Intelligent holographic three dimension laser measuring system

A technology of 3D laser and measurement system, which is applied in measurement devices, optical devices, instruments, etc., to achieve the effect of improving measurement accuracy, high integration, and rapid evaluation of 3D surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

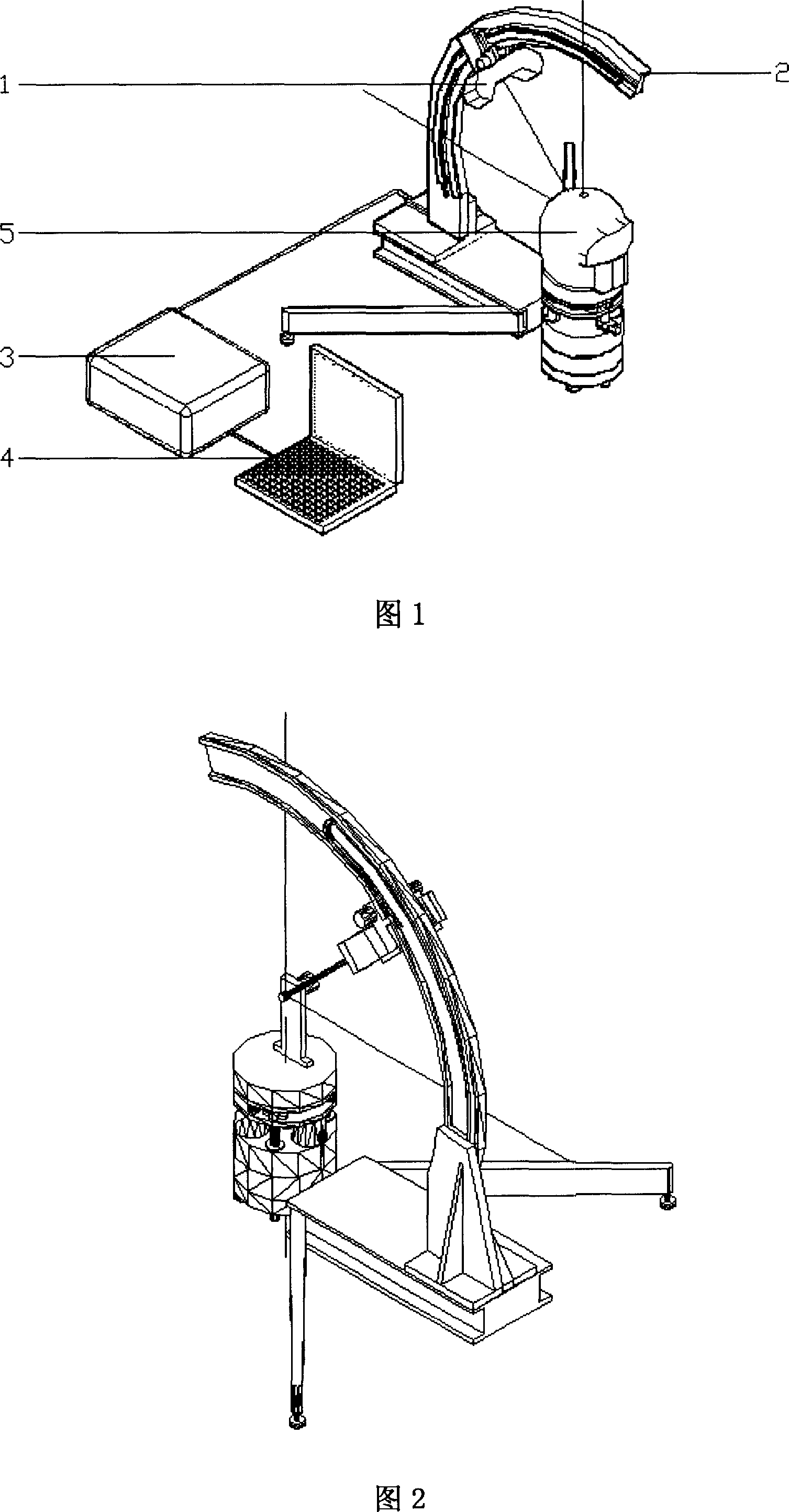

[0038] The best implementation example is as follows in conjunction with the aforementioned operation steps:

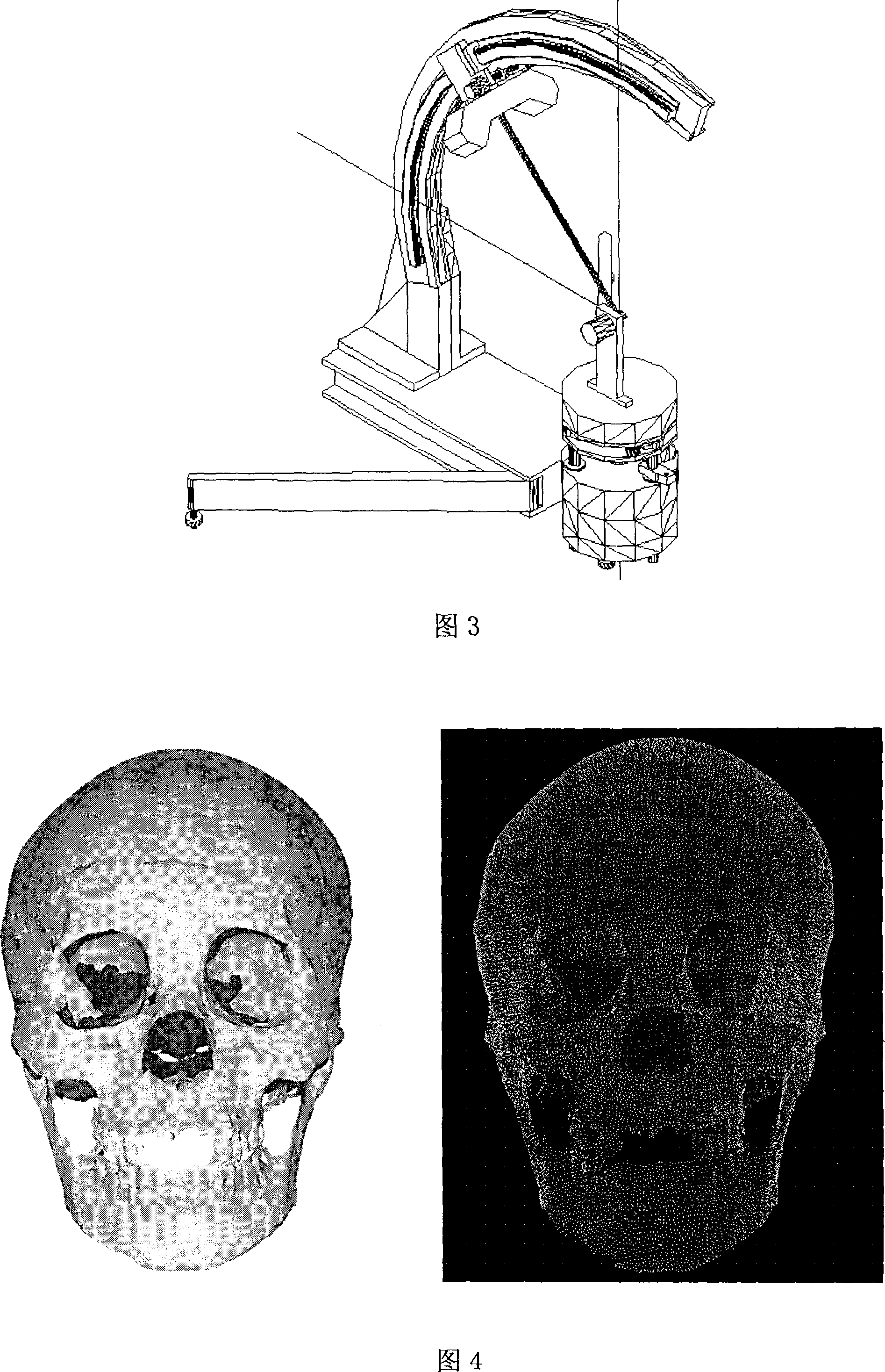

[0039]Laser measuring head 1 is a non-contact binocular laser measuring head. The laser light source adopts a 650nm semiconductor laser. The width of the linear laser beam is less than 1mm. A connecting joint that can adjust the pitch angle and steering angle of the CCD camera is used between the CCD camera of the acquisition system and its bracket. The high-precision arc-shaped slide rail and slider are fixed on the C-shaped measuring arm of the holographic scanner 2, and the bracket supporting the laser probe 1 is vertically fixed on the slider so that the linear laser beam passes through the center of the arc-shaped slide rail and The central axis of the lifting turntable of the holographic scanner 2. The slider can make a precise arc movement relative to the center of the arc-shaped slide rail. The bracket fixed on the slider is composed of a U-shaped frame, a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com