Coating apparatus and process for longoptic fiber grating

A fiber grating and coating device technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of difficulty in ensuring coating uniformity, fiber grating reflection, time delay and other characteristics degradation , to achieve the effects of low cost, improved mechanical stress resistance, and high-quality curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

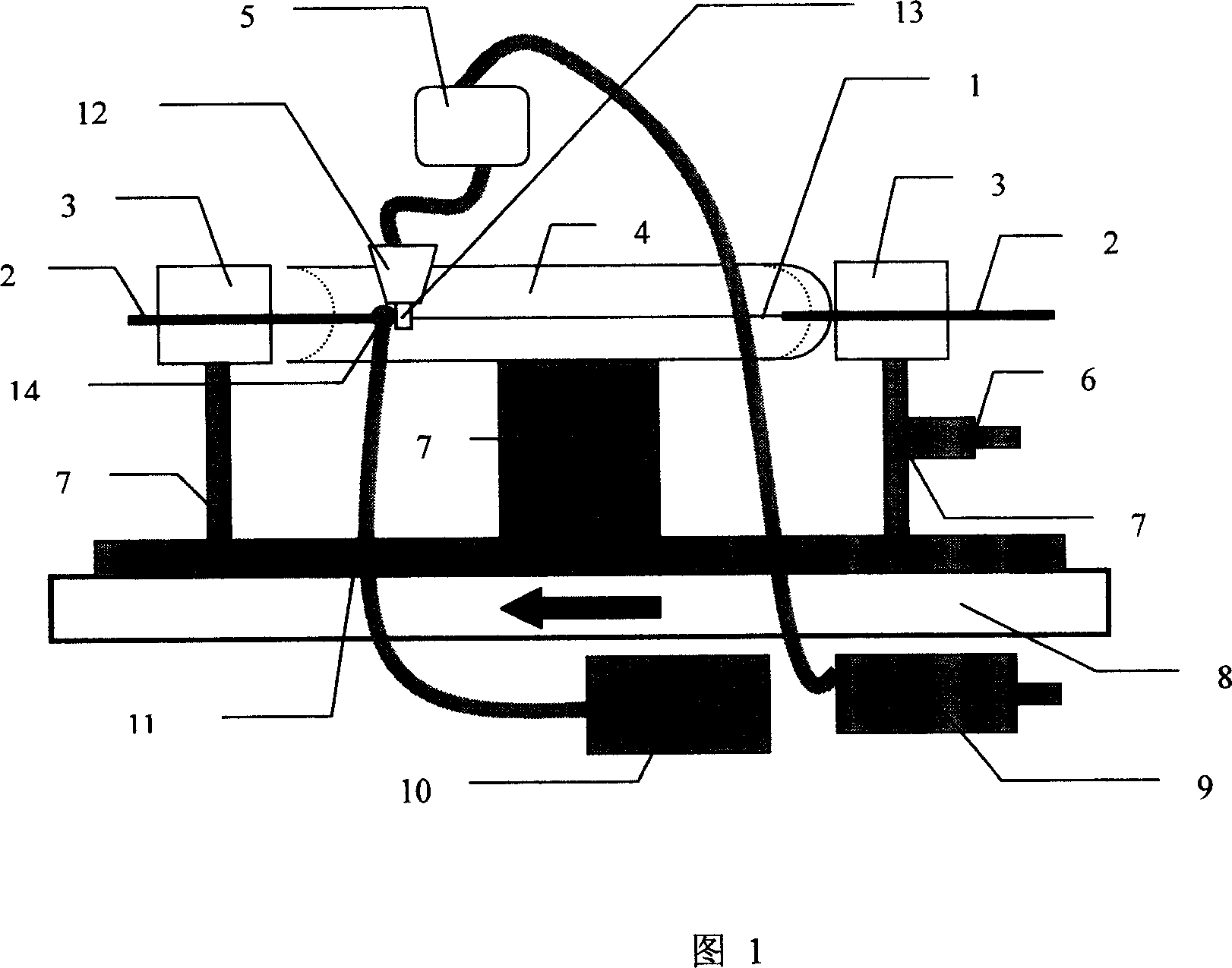

[0019] As shown in Figure 1, the bottom is a high-precision mobile platform 8 controlled by a computer, that is, the ESP 300 motor. The black arrow in the figure indicates the direction in which the fiber grating moves, and its function is to control the movement of the fiber grating during the coating process. The moving range of the moving platform 8 is 200mm, so that the length of the coated fiber grating can reach up to 200mm. The optical adjustment frame 7 is carried on it, and two parts are installed on the optical adjustment frame 7: one part is an optical fiber clamp 3 with a V-shaped groove, which is used to clamp the coated optical fiber 2 part, and the optical fiber clamp on the right side is simultaneously equipped with There is a stress adjustment device 6, which is used to adjust the distance between the two fixtures. When adjusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com