Bowl-type medium speed coal mill

A technology of coal mill and medium speed, applied in the field of bowl type medium speed coal mill, can solve the problems of downtime, inconvenient maintenance and high external size of the coal mill, reduce vibration, reduce failure rate and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

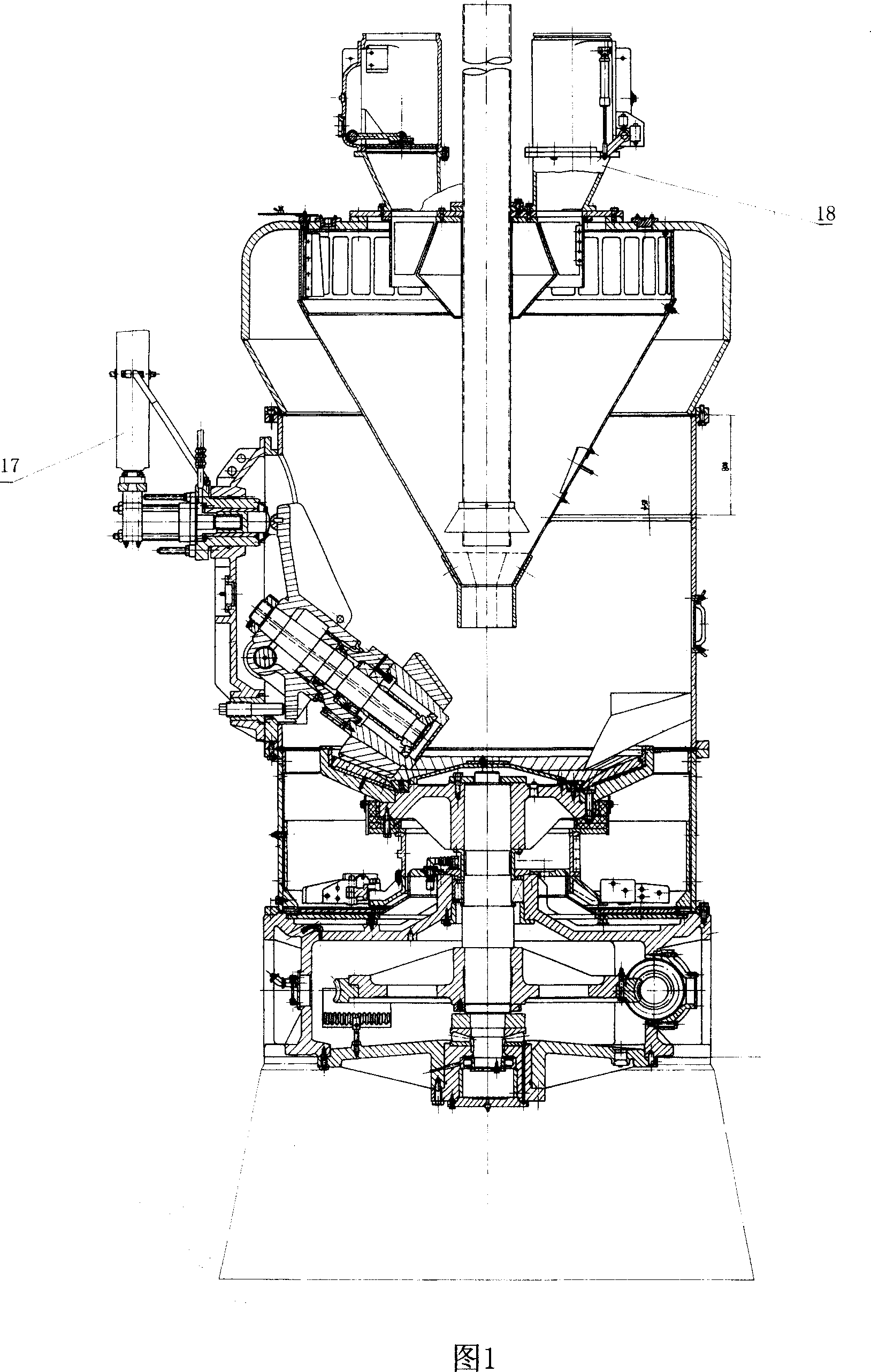

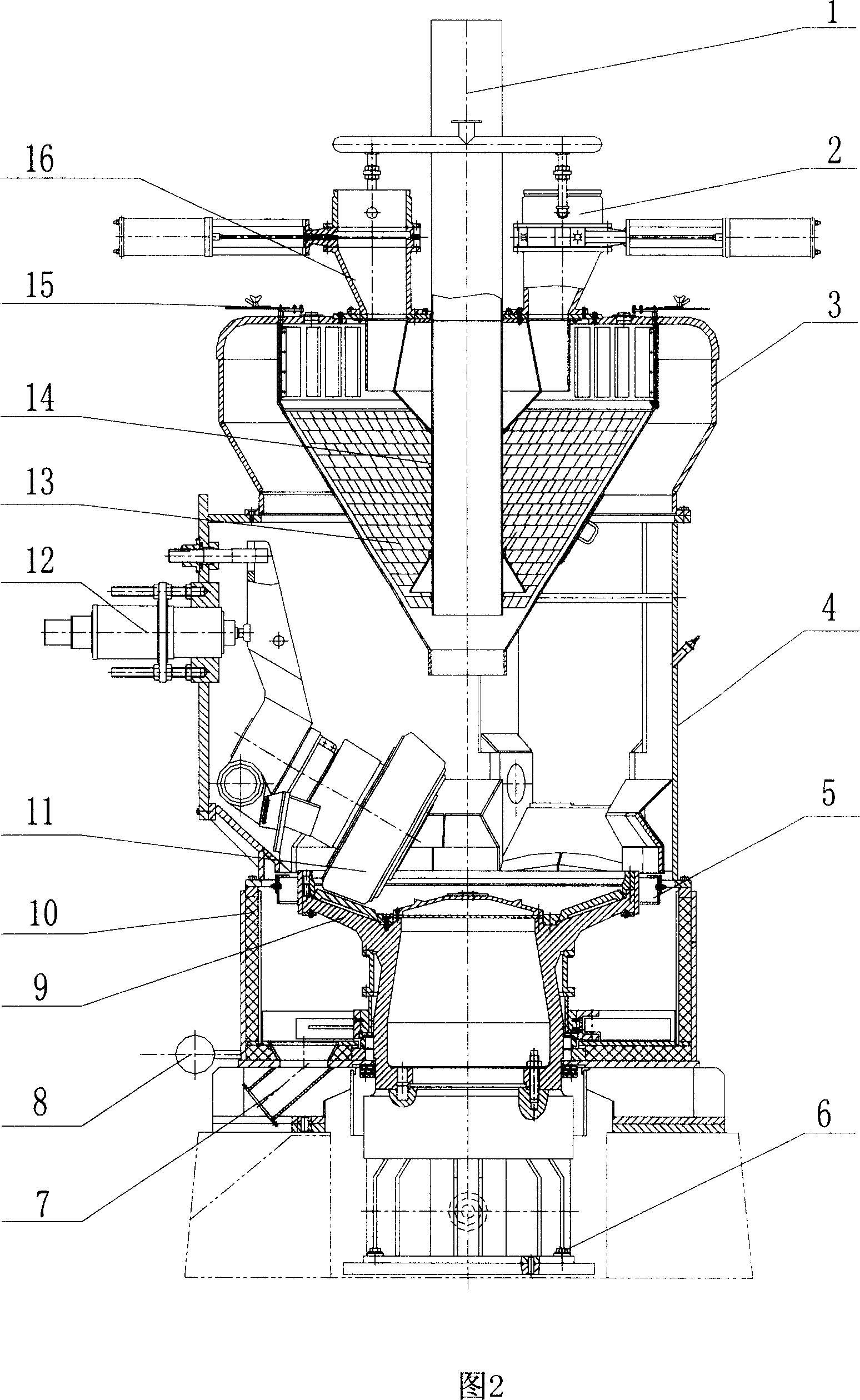

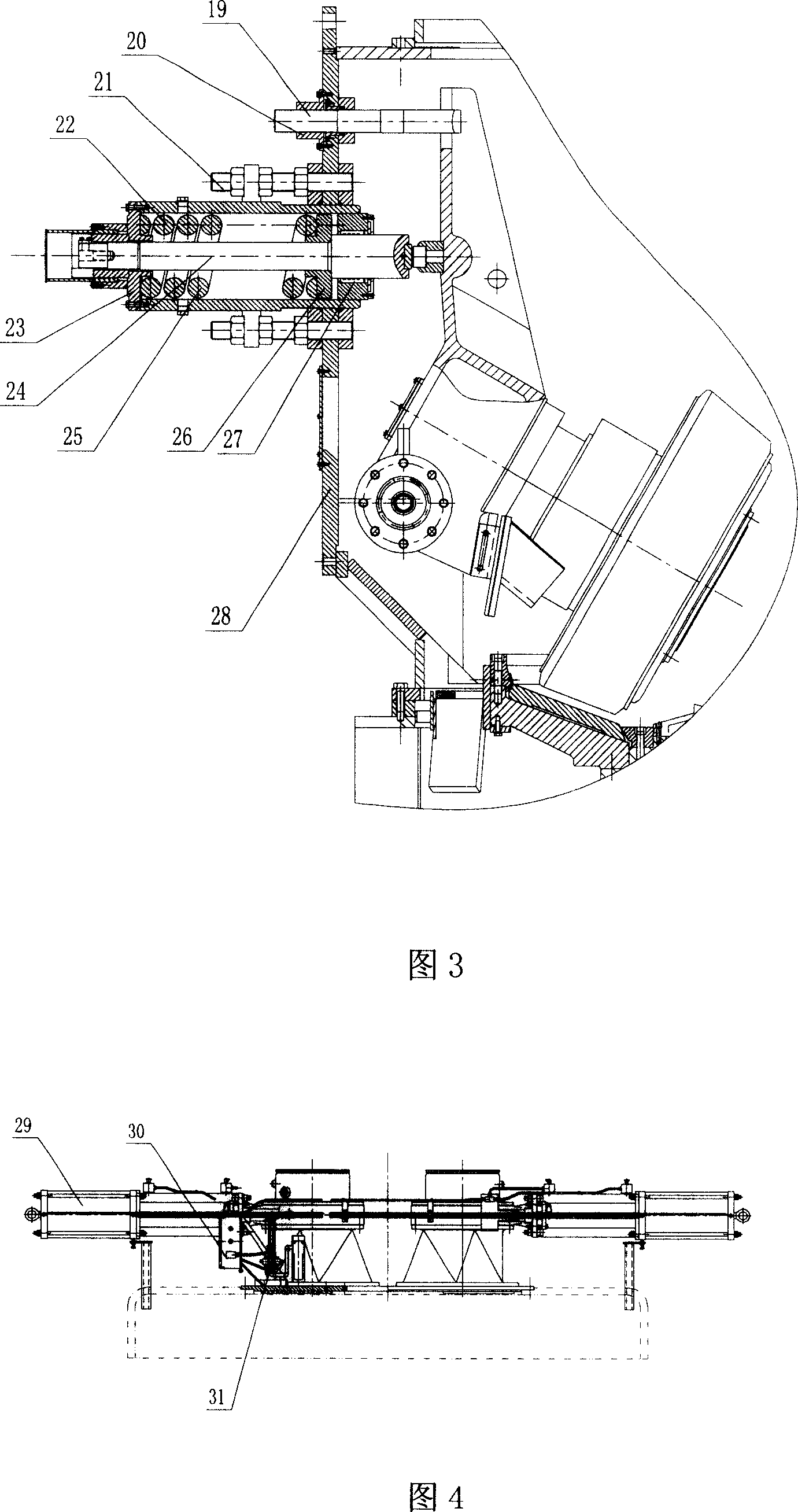

[0016] As shown in Figure 2, the bowl-type medium-speed coal mill of the present invention mainly includes: a coal drop pipe 1, a separator top cover 3, an inner cone 13, a separator body 4, an impeller device 5, a reduction box 6, and a discharge valve device 2. Folding door adjustment device 15, venturi tube 14, spring variable loading device 12, side body device 10, grinding roller device 11, bowl grinding device 9, sealed air header 8, pebble coal discharge port 7, multiple outlets Device 16 etc.

[0017] The reduction box 6 is composed of planetary gears, has an appropriate reduction ratio, and is directly driven by the electric motor. The reduction box 6 is directly connected with the grinding bowl device 9 to make the grinding bowl reach the required rotating speed. The side body device 10 is equipped with a liner, forms an air inlet around the grinding bowl, and supports the separator body 4, and the hot air used for drying and transporting coal powder is introduced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com