Online tobacco steam expanding apparatus and relevant tobacco stem treating method

A technology of expansion treatment and treatment method, applied in the field of tobacco stem online expansion equipment, can solve problems such as waste of steam energy, clogging, complicated pre-processing procedures, etc., and achieve the goal of saving steam energy, improving treatment efficiency, and improving online expansion treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

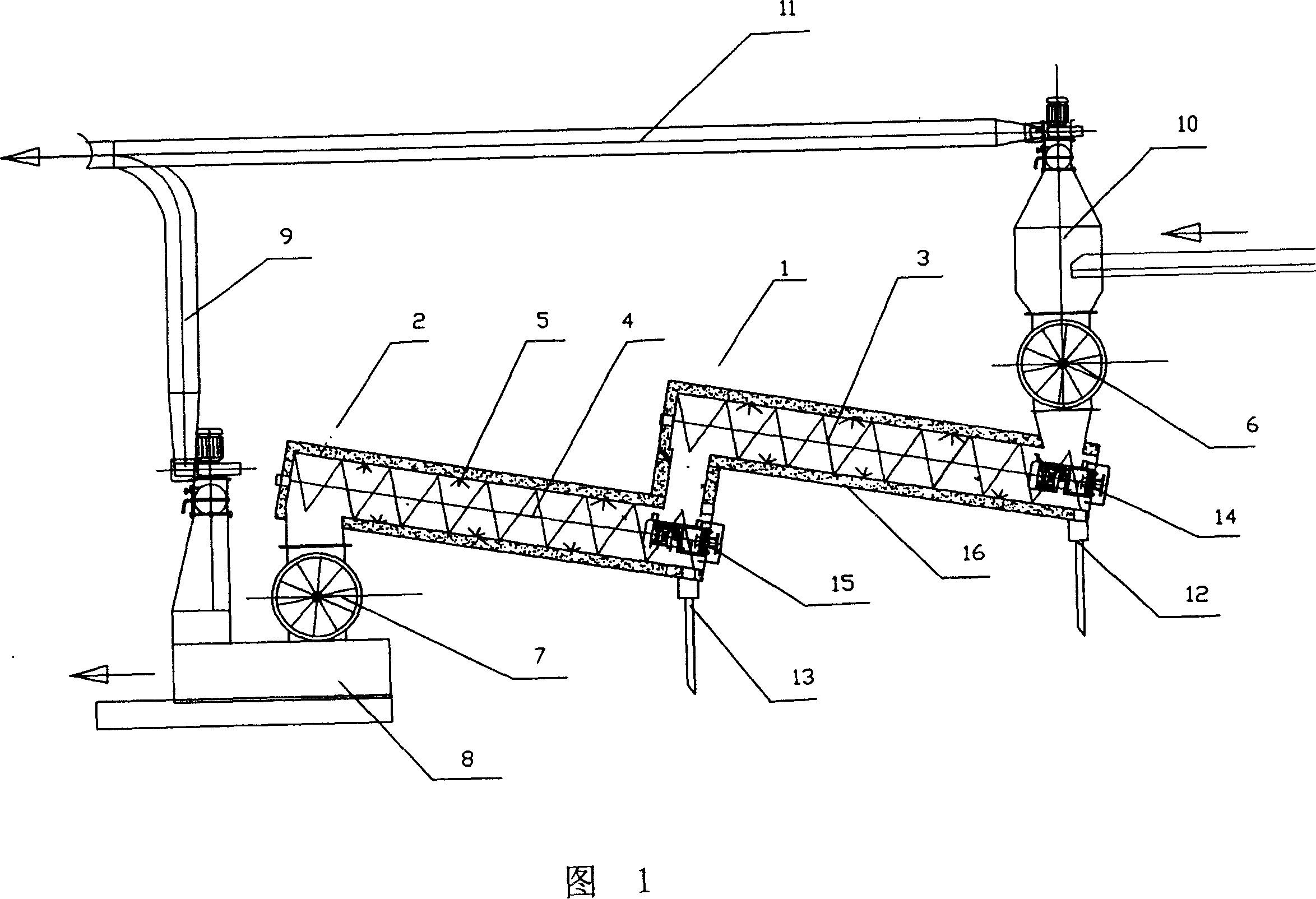

[0030] The tobacco stem online expansion equipment involved in the present invention mainly includes a pressurized steam treatment device and steam airlocks respectively arranged at the inlet and outlet of the pressurized steam treatment device.

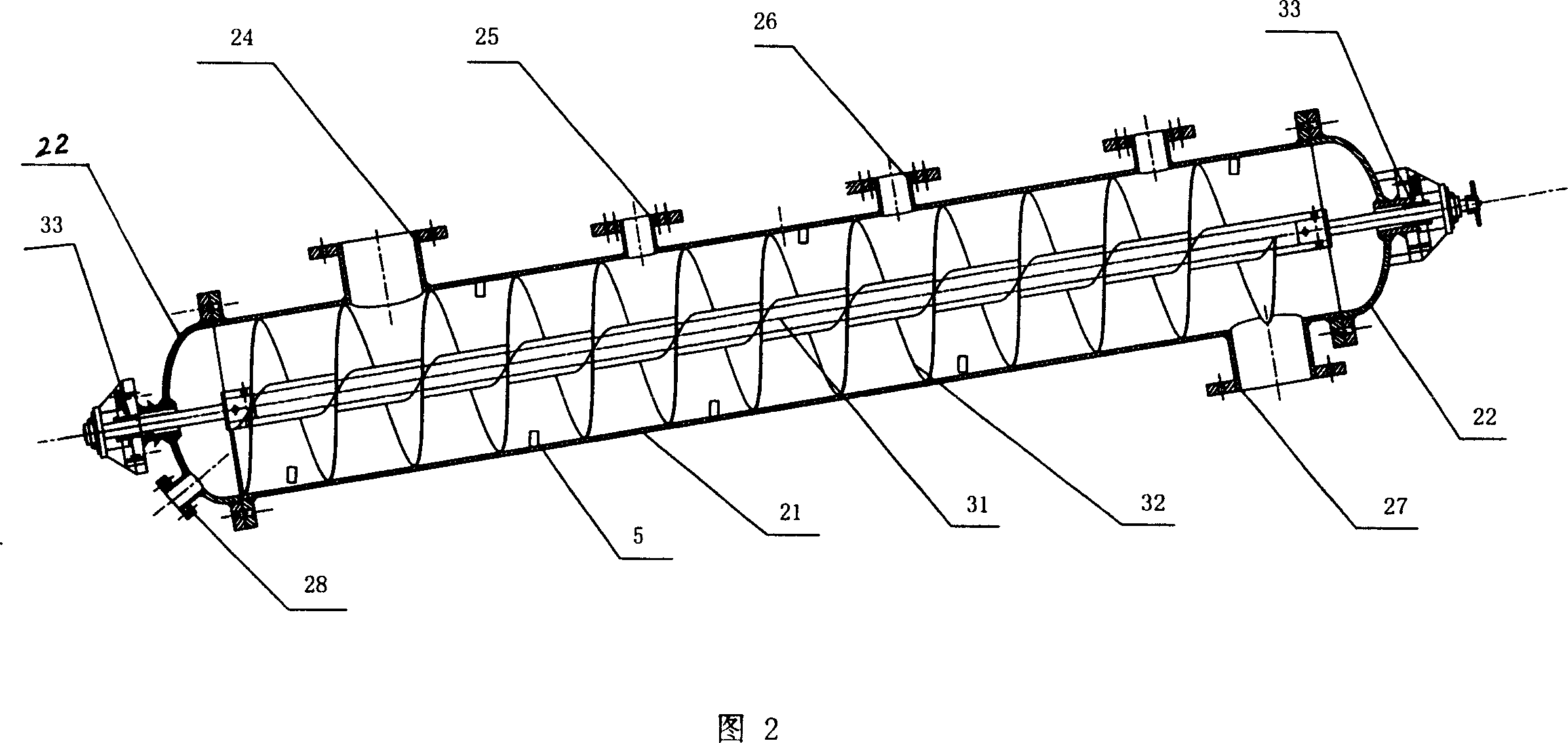

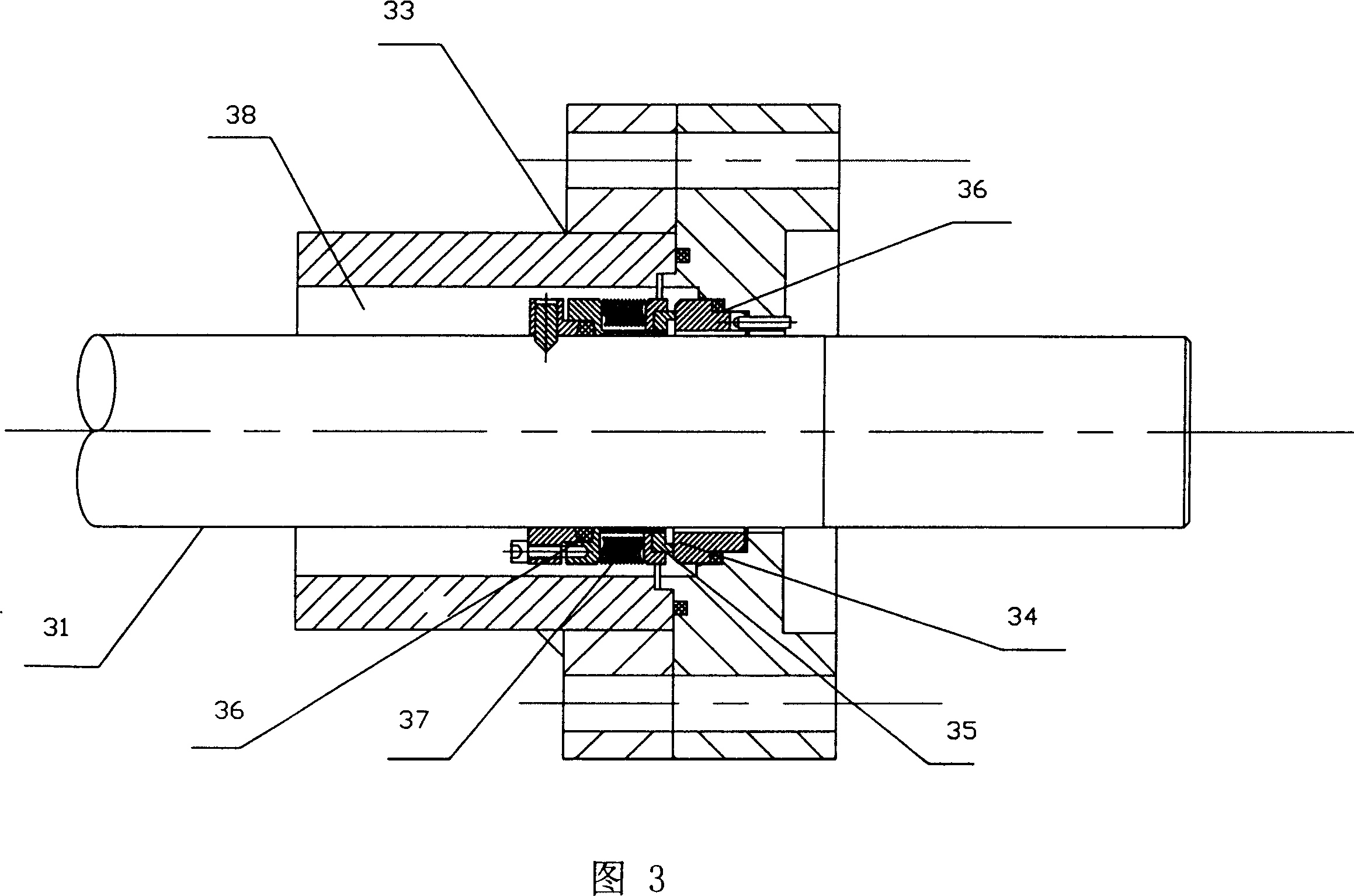

[0031] As a preferred embodiment, as shown in Figure 1, the pressurized steam treatment device includes a first pressurized treatment chamber 1 and a second pressurized treatment chamber 2 with the tail slightly inclined upwards; the first pressurized treatment chamber 1 The outlet below the tail is directly connected to the inlet above the head of the second pressurized treatment chamber 2; the first pressurized treatment chamber 1 and the second pressurized treatment chamber 2 are both equipped with a screw conveying device 3, 4; the screw conveying device 3, 4 Driven by speed-adjustable driving motors 14 and 15 respectively; several steam injection nozzles 5 are evenly arranged along the circumference and axial direction of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com