Tyre surface line-plotting device

A tire and positioning wheel technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of non-parallel circumferential lines and tire edges, increase the difficulty of drawing lines, and fail to achieve drawing effects, and achieve a simple structure. , low cost, high parallelism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

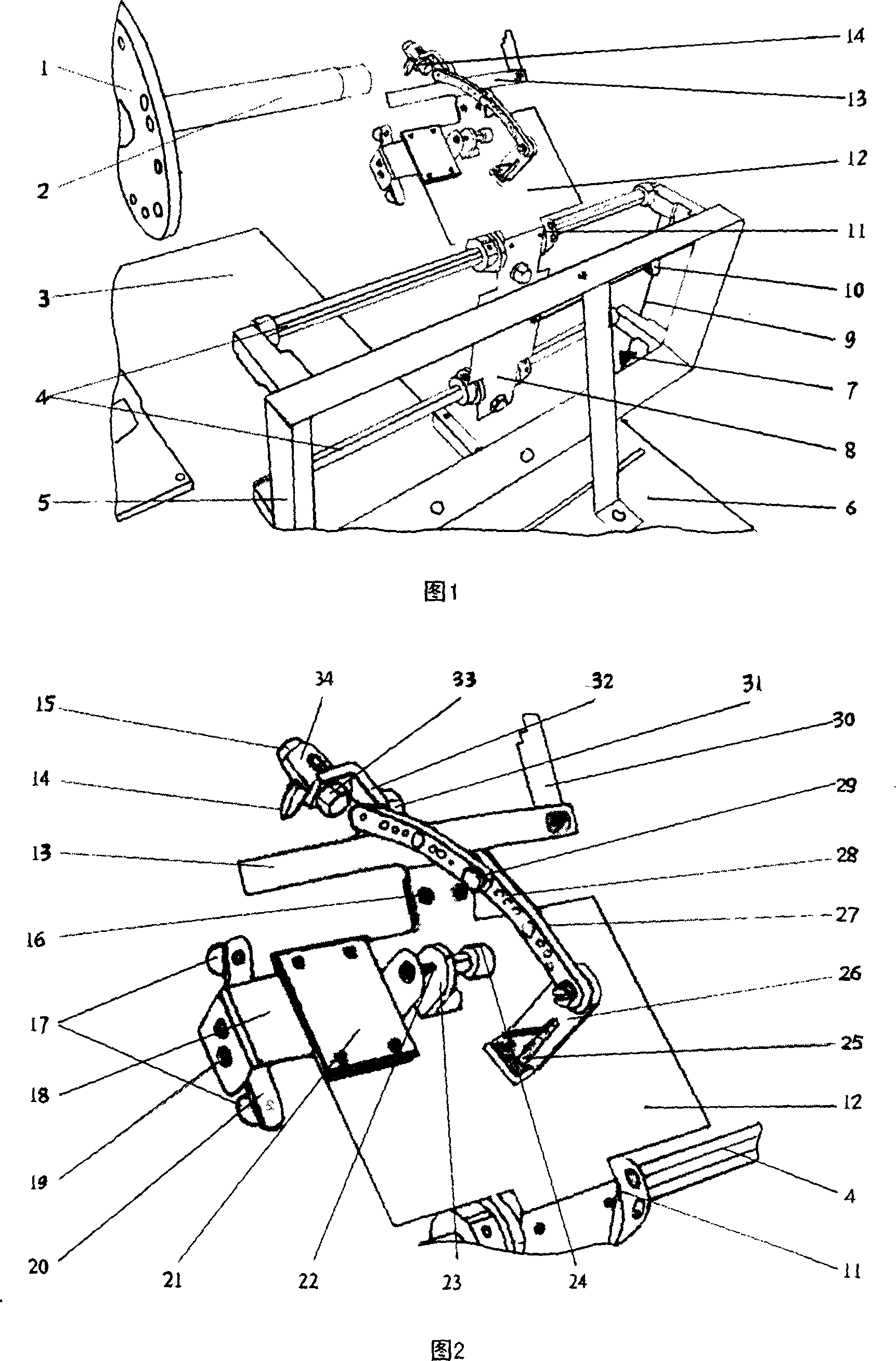

[0013] Below, the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0014] The tire surface drawing device described in Fig. 1 is made up of five major parts of fixing and supporting mechanism, floating positioning mechanism, fine-tuning mechanism, scale and drawing line mechanism; Mechanism, fine-tuning mechanism, ruler and line-drawing mechanism are connected.

[0015] The fixation and support mechanism of this tire surface drawing device is as described in Fig. 1, is made of base 3, main shaft 2, connection plate 1, tool holder 6, support 5 and slide rail 4, pallet 12 etc.; Fixed support mechanism has a Main shaft 2, the main shaft 2 is equipped with a connecting plate 1, a tool seat 6 is movably connected with the base 3, the bracket 5 is fixed on the tool seat 6 by bolts, the main shaft 2 is connected with the bearing seat on the bracket 5 through a bearing, the main shaft 2 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com