Filter for removing minim moisture from organic solvent

A technology for removing organic solvents and trace amounts of water. It is applied to fixed filter element filters, filtration separation, and liquid separation. It can solve the problems of filter element clogging, high cost and high price of composite membranes, and extend the service life and improve the water removal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

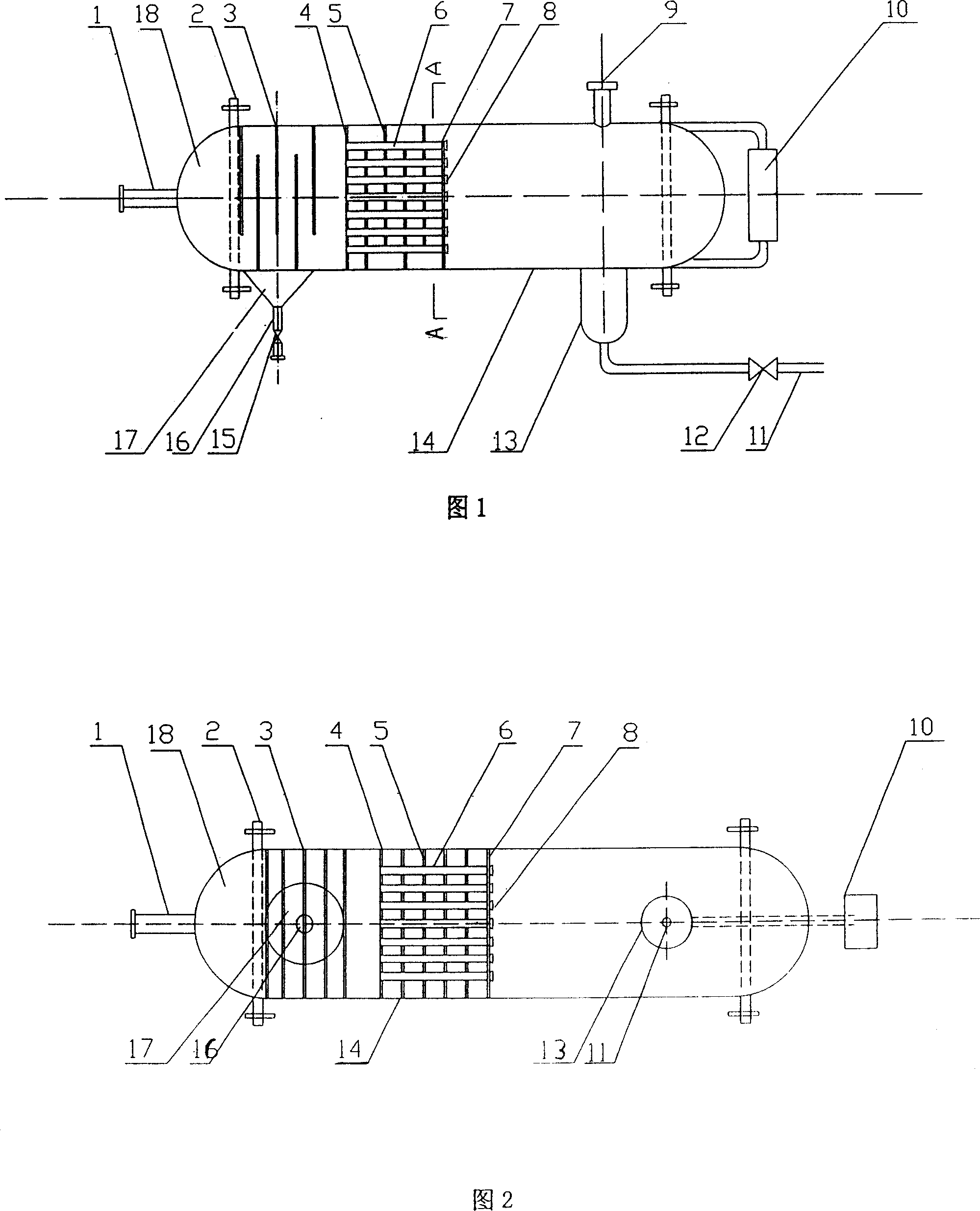

[0025] Embodiment 1: The following components are connected in the manner shown in Fig. 1-Fig. 3, and those skilled in the art can implement it smoothly. The filter housing 14 has a length of 1.6 meters, an outer diameter of 159 mm, a wall thickness of 4.5 mm, and is made of 304 stainless steel. The vertical dividing plate 3 is 5 pieces, the thickness of each piece is 4mm, the thickness of the perforated fixed plate 4 is 6mm, the thickness of the perforated dividing plate 5 is 5mm, the inner diameter of the filter core tube 6 is 10mm, and the thickness of the filter medium layer is 2.5mm. The thickness of the plate 7 is 6 mm, the size of the discharge pipe 9 is φ18×1.5 mm, the control liquid level gauge 10 adopts a float level controller, and the moisture storage tank 13 has a capacity of 1 liter. The device is used in a small enterprise to remove trace moisture in phenol-acetone mixed organic solvents. Before filtration, the mixed organic solvents not only contain nearly 100p...

Embodiment 2

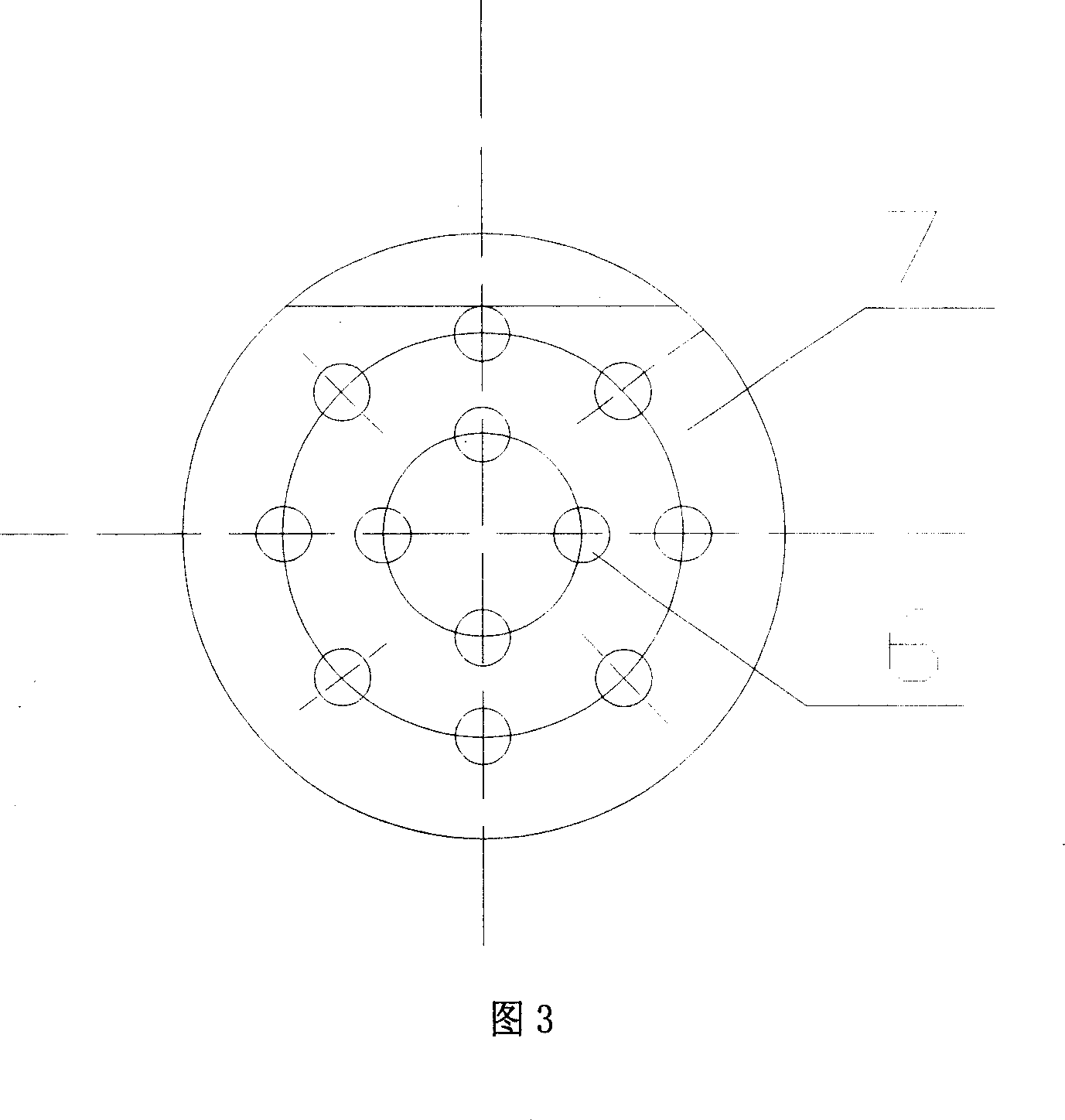

[0028] Embodiment 2: The filter housing 14 has a length of 1.8 meters, an outer diameter of 169 mm, a wall thickness of 4.5 mm, and is made of 304 stainless steel. The vertical dividing plate 3 is 5 pieces, the thickness of each piece is 4mm, the thickness of the perforated fixed plate 4 is 6mm, the thickness of the perforated dividing plate 5 is 4mm, the inner diameter of the filter core tube 6 is 12mm, the thickness of the filter medium layer is 3mm, the filter core tube Arranged in two circles, the number of filter tubes in the inner and outer circles is 4 and 8 respectively, the total number is 12, the thickness of the fixed plate 7 is 6mm, the size of the discharge pipe 9 is φ18×1.5mm, and the control liquid level gauge is 10 Adopt float level controller, moisture storage tank 13 capacity is 1.5 liters. The device is used to remove the residual moisture in the oil of an oil refining enterprise. The oil product passes through the mechanical filtration of the vertical part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com