Hollow four plane tie-in

A flat, hollow technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of high cost of conversion fittings, uneven current distribution, blown tube busbar, etc., to save non-ferrous metals, save energy, The effect of reducing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

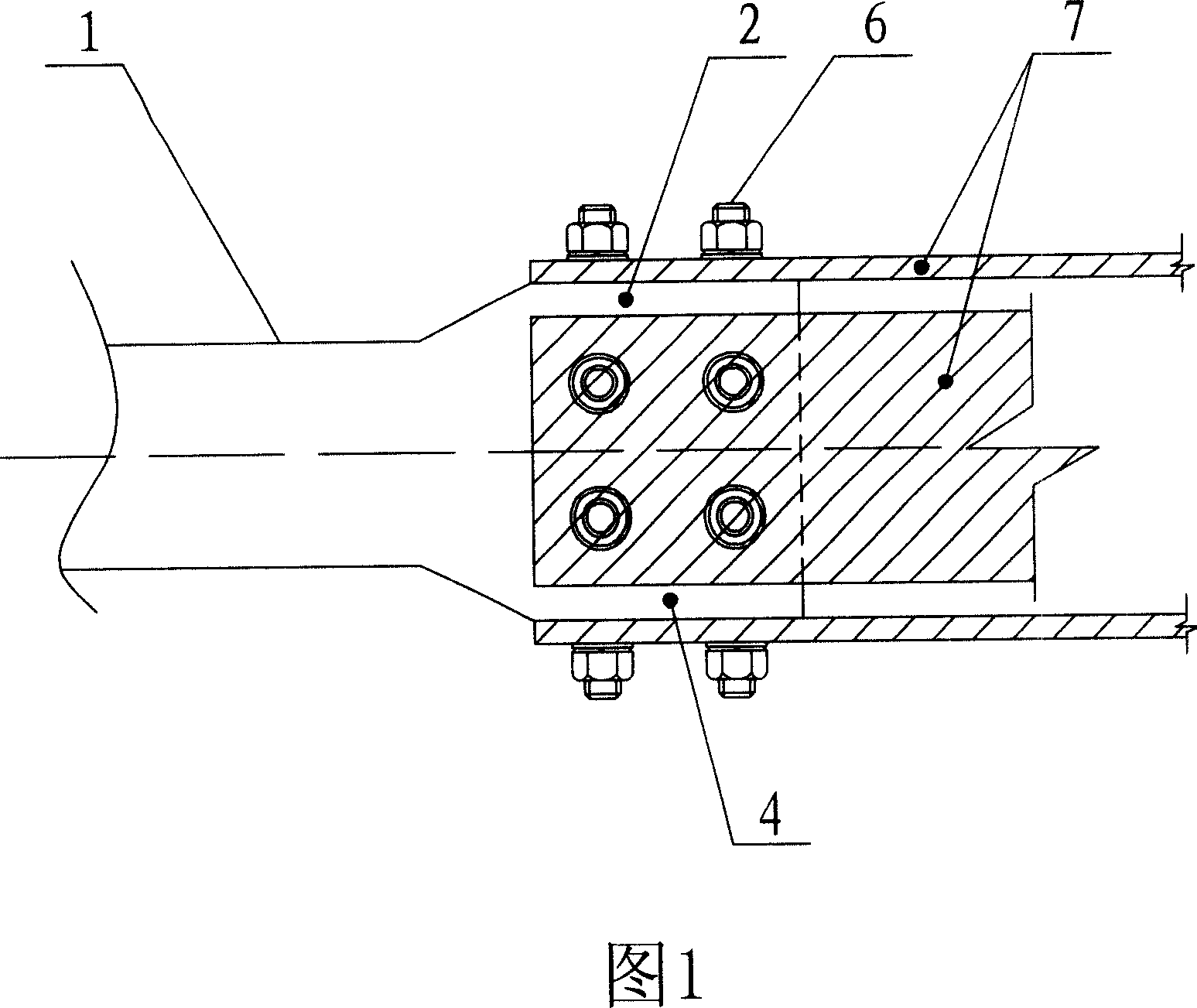

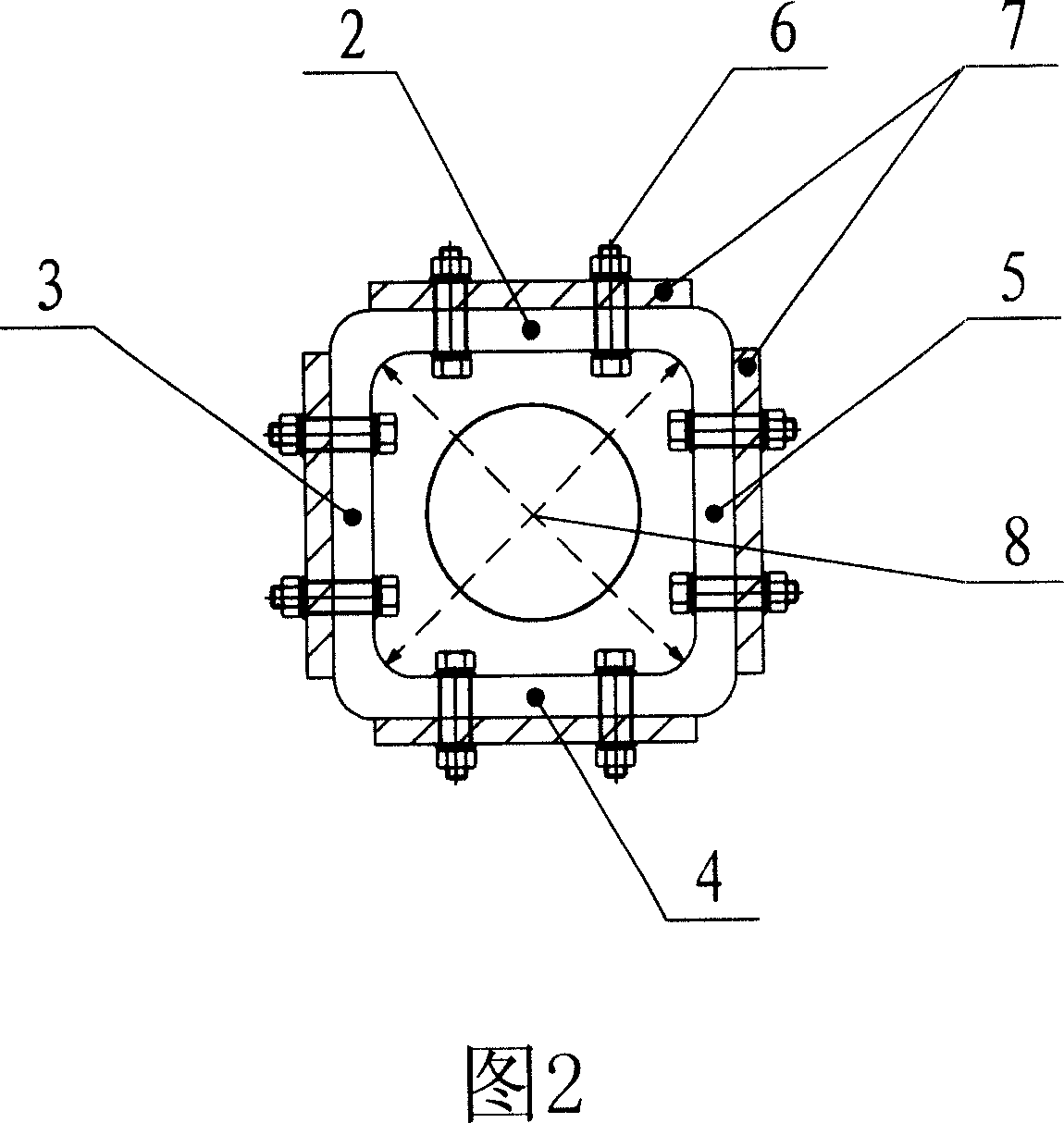

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] As shown in Figure 1, the hollow four-plane joint of the present invention is a hollow four-plane joint in which the end of the tube bus bar is formed by stamping and forming hollow four conductive planes. The four conductive planes are connected, and the four conductive planes are connected. There is a certain heat dissipation space between the planes, and the 4 conductive planes formed by this stamping are connected with other devices through rectangular conductors or soft connections, which form a heat-dissipating hollow four-plane joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com