Multilayer tubular busbar structure

A technology of tubular busbar and busbar structure, which is applied in busbar installation, cooling busbar device, fully enclosed busbar device, etc., can solve the problems of current carrying, heat dissipation, material saving, etc. Mature technology, flexible splicing, and the effect of air convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

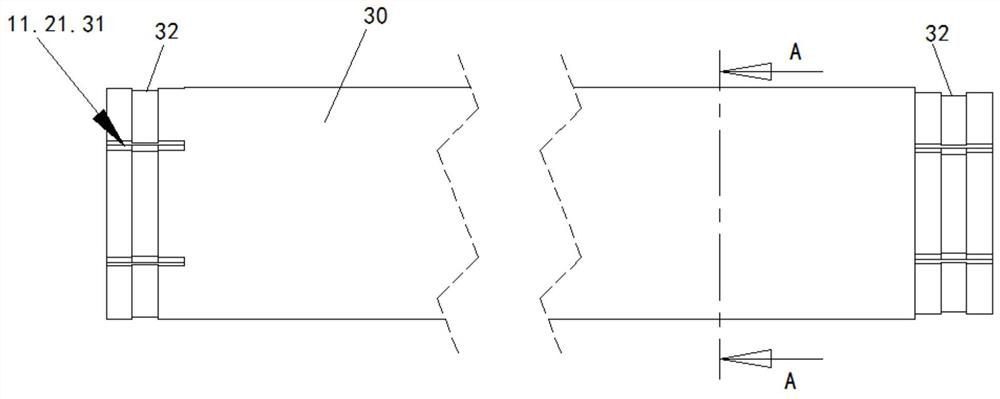

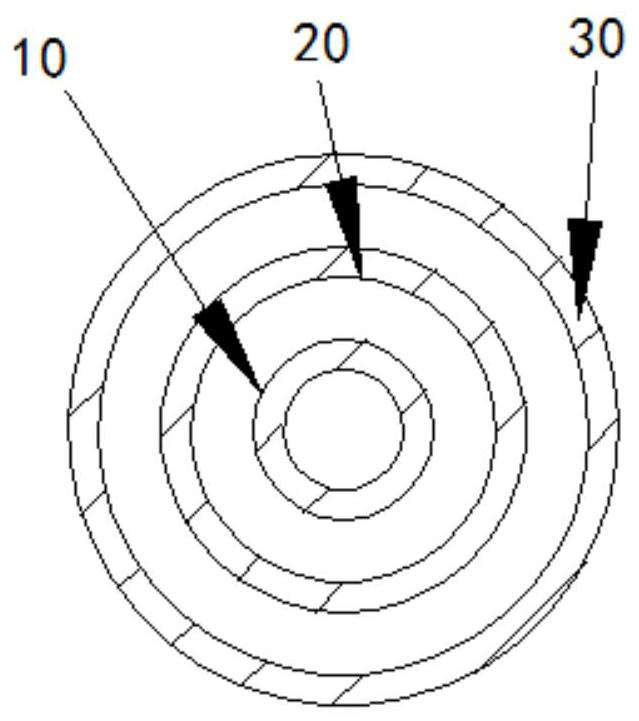

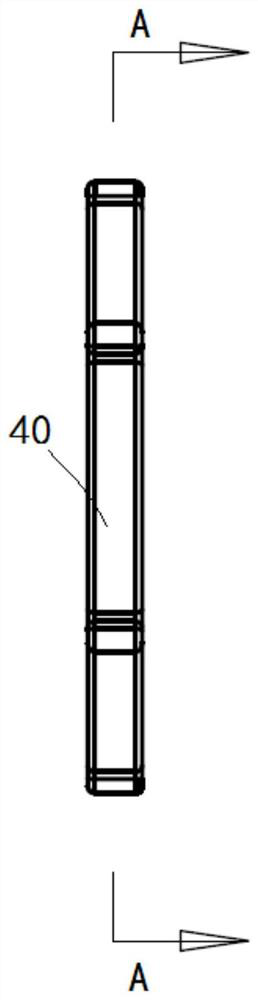

[0028] The following uses the three-layer tubular bus structure as an example to illustrate the multi-layer tubular bus structure of the present invention. Of course, the present invention is not limited to the three-layer tubular bus structure, and may also be a two-layer tubular bus structure or more than three layers Tubular busbar structure. The multi-layer linear tubular busbar uses copper pipes of different diameters for multi-layer layout. According to the product application occasion and current carrying size and other factors, the number of layers can be adjusted and configured from 1 to N layers.

[0029] see figure 1 and figure 2 , the three-layer linear tubular busbar shown in the figure includes three layers of linear tubular busbars arranged from the inside to the outer layer, that is, the inner layer linear tubular busbar 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com