Preparing method of anode material of lithium cobalt, nickel, manganese, oxygen lithium ion battery

A lithium-nickel-manganese-cobaltoxylithium and ion battery technology, applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of less than 2 microns (usually 0.5-2 microns) that cannot meet actual needs, and achieve Improve the specific capacity and cycle stability, improve the appearance and shape, and facilitate the infiltration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is used to illustrate that the secondary ball cathode material LiNi provided by the present invention 1 / 3 mn 1 / 3 co 1 / 3 o 2 method of preparation.

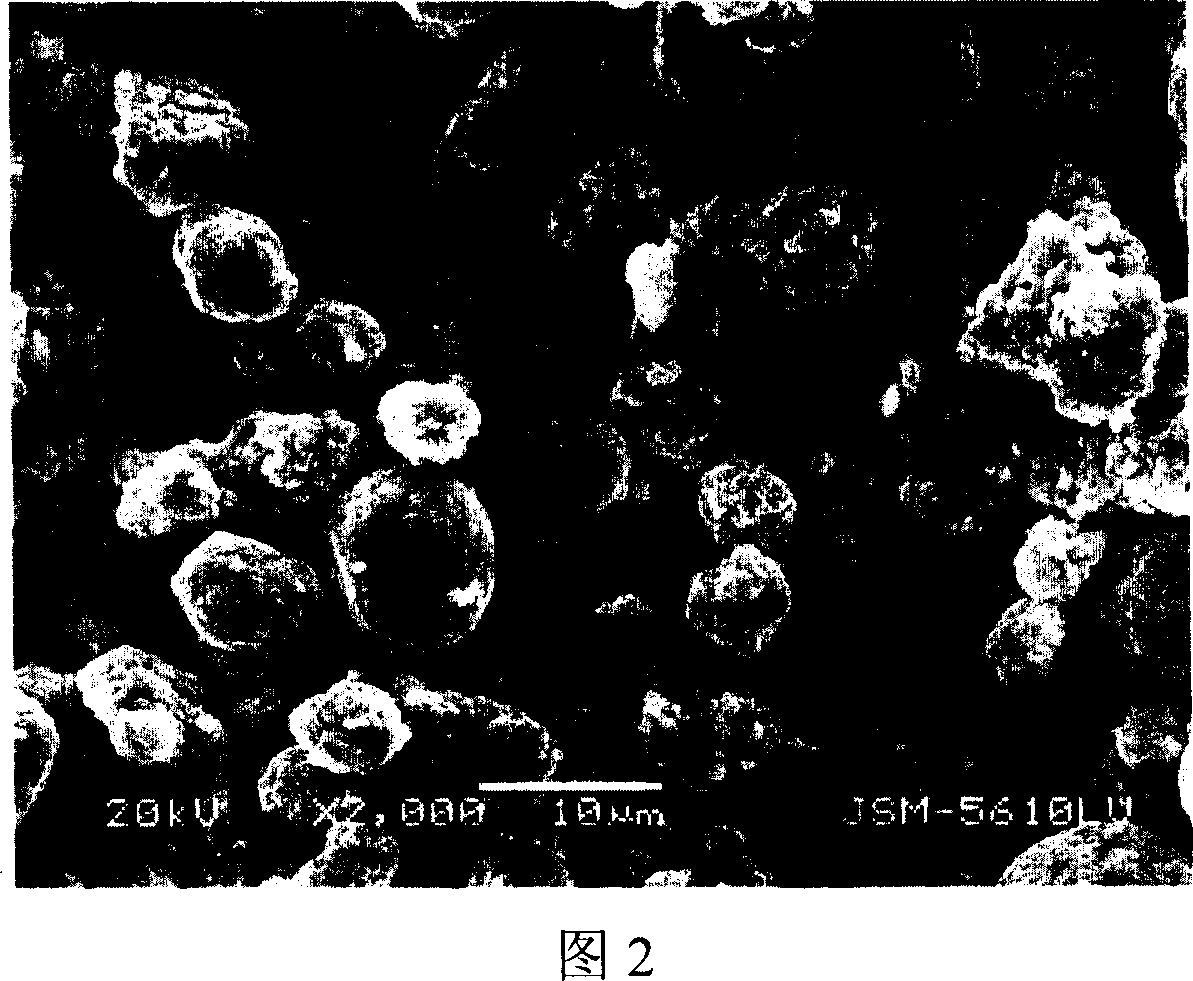

[0028] 1 mole of nickel cobalt manganese hydroxide Ni with an average particle size of 0.6 micron 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 Put it into the intermittent fluidized bed granulator, feed compressed air at 110°C at a speed of 5 m / s, the precursor nickel cobalt manganese hydroxide Ni 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 Fluidize rapidly in the fluidized bed granulator, simultaneously with spray gun, 500 gram concentrations are sprayed in the fluidized bed granulator with the sodium carboxymethyl cellulose aqueous solution of 1% by weight, and the speed of injection is 5 g / min, Obtain spherical secondary particles; put the obtained secondary particles into a high-temperature furnace at 300°C for one-stage sintering for 4 hours to obtain a one-stage sintered product, and then mix the obtained one-stage sintered produc...

Embodiment 2

[0031] This embodiment is used to illustrate that the secondary ball cathode material LiNi provided by the present invention 2 / 5 mn 2 / 5 co 1 / 5 o 2 method of preparation.

[0032]Repeat the steps of Example 1 to prepare positive electrode material LiNi 2 / 5 mn 2 / 5 co 1 / 5 o 2 , the difference is that the nickel manganese cobalt hydroxide used is Ni 2 / 5 mn 2 / 5 co 1 / 5 (OH) 2 .

[0033] For the above LiNi 2 / 5 mn 2 / 5 co 1 / 5 o 2 The powder is analyzed with an IRIS Advantange 1000ICP-AES type plasma emission spectrometer, and the recorded Li, Mn, Ni, and Co contents are respectively 7.22% (7.22% in theory), 22.85% (22.85% in theory), and 24.29% (in theory 22.33%), 12.25% (theoretical 12.25%). Particle size analysis was carried out with a MASTERSIZER laser particle size analyzer, and the measured D 50 = 11.63 microns.

Embodiment 3

[0035] This embodiment is used to illustrate that the secondary ball cathode material LiNi provided by the present invention 2 / 5 mn 2 / 5 co 1 / 5 o 2 method of preparation.

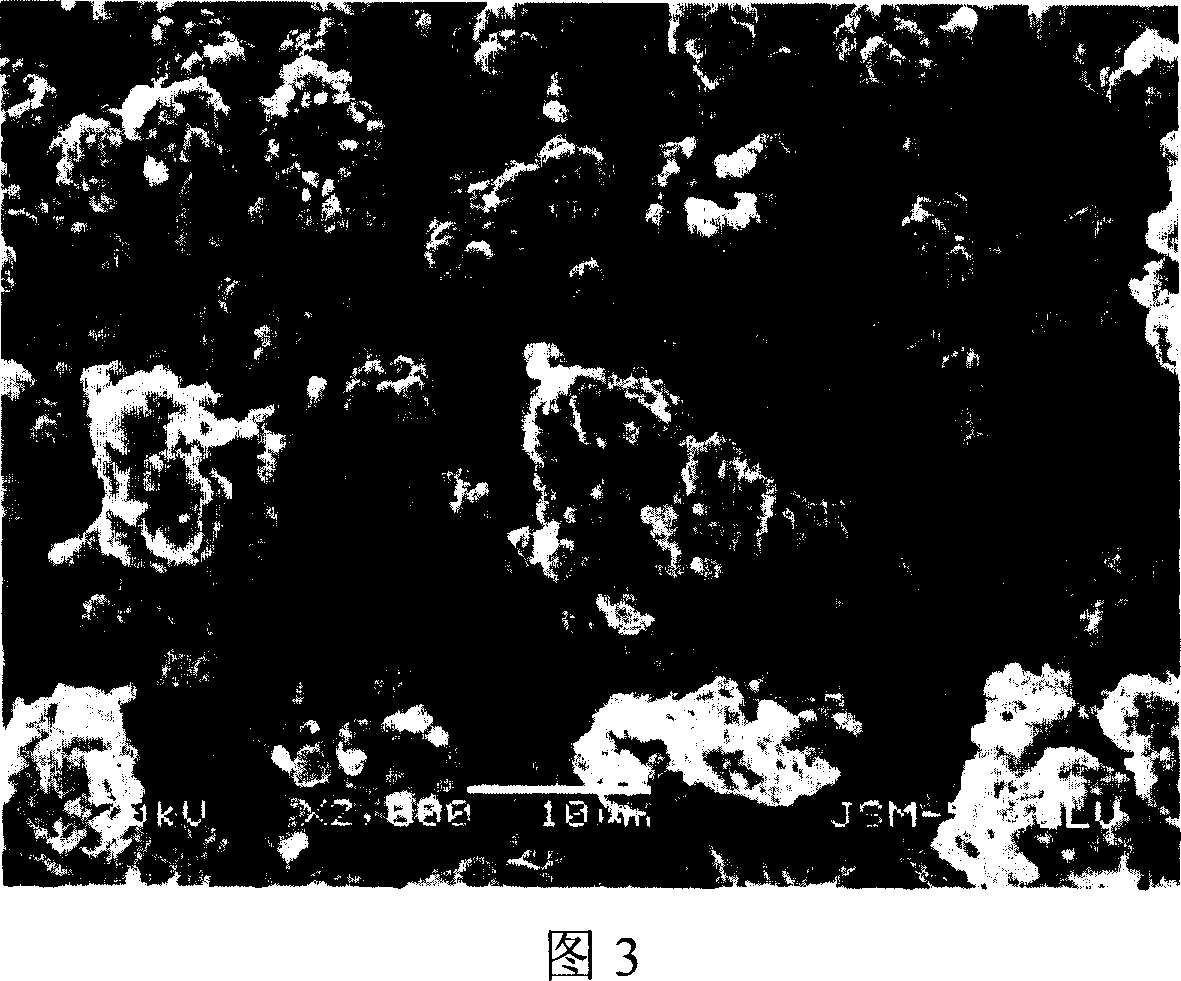

[0036] Take by weighing 1 mole of nickel nitrate, 1 mole of manganese nitrate and 1 mole of cobalt nitrate in the ratio of Ni:Mn:Co=1:1:1 and dissolve them in 750 milliliters of deionized water to form a solution of 4 moles / liter. Slowly add 1500 milliliters of 4 mol / liter NaOH aqueous solution under stirring conditions, control the temperature of the solution to 50°C, stir for 3 hours and then filter to obtain nickel manganese cobalt hydroxide Ni with an average particle size of 0.5 microns. 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 ; The above-mentioned nickel manganese cobalt hydroxide Ni 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 Add it to the fluidized bed granulator, feed compressed air at 120°C at a speed of 1 m / s, the precursor nickel cobalt manganese hydroxide Ni 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 Fluidize rapidly in the fluidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com