Hydrogenation catalyst

A catalyst and hydrotreating technology, applied in refining to remove heteroatoms, etc., can solve the problem of low catalyst activity and achieve good hydrofining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

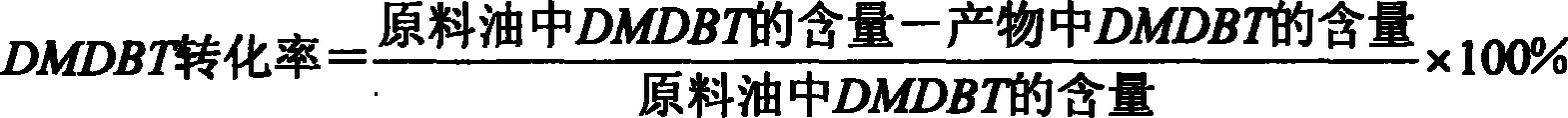

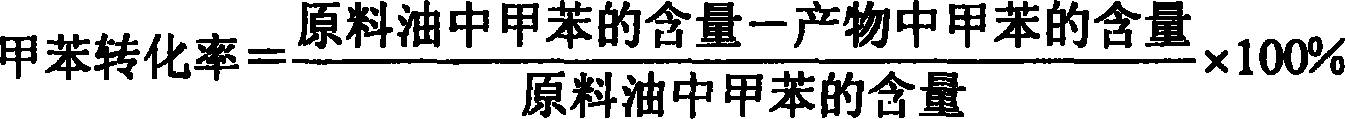

Method used

Image

Examples

example 1

[0023] Take by weighing 2000 grams of aluminum hydroxide powder (dried rubber powder produced by Changling Branch Catalyst Factory) and 160 grams of silica gel (produced by Qingdao Ocean Chemical Factory) and mix, and extrude into a clover-shaped strip with a circumscribed circle diameter of 1.4 mm , wet strips were dried at 120°C for 4 hours. Take 1000 grams of this dry strip, and process it for 4 hours under the conditions of 600°C at a volume ratio of air to water vapor of 1:3, a gas flow rate of 1.6 cubic meters / kg.hour, and a temperature of 600°C to obtain the carrier S 1 , Determination of carrier S 1 The silicon oxide content is 10.0w%.

[0024] Take carrier S 1 100g, impregnated with 90ml of aqueous solution containing 10.2g of ammonium molybdate for 3 hours, dried at 120°C for 5 hours, then impregnated with 83ml of aqueous solution containing 18.0g of nickel nitrate and 34.8g of ammonium metatungstate for 1 hour, and dried at 160°C 4 hours, to obtain catalyst C 1 . ...

example 2

[0029] Take carrier S 1 100g, impregnated with 90ml of aqueous solution containing 8.6g of ammonium molybdate for 3 hours, dried at 120°C for 5 hours, then impregnated with 83ml of aqueous solution containing 18.7g of nickel nitrate and 42.7g of ammonium metatungstate for 1 hour, and dried at 160°C 4 hours, to obtain catalyst C 2 . Catalyst C 2 The contents of Mo, Ni and W are listed in Table 1.

example 3

[0031] Weigh the carrier S 1 100 grams, impregnated with 88 ml of an aqueous solution containing 5.8 grams of ammonium molybdate and 31.0 grams of glycerol for 3 hours, dried at 120°C for 5 hours, and then impregnated with 85 ml of an aqueous solution containing 19.3 grams of nickel nitrate and 56.9 grams of ammonium metatungstate 1 hour, dried at 160°C for 4 hours to obtain catalyst C 3 . Wherein the molar ratio of glycerol to nickel, molybdenum and tungsten in terms of oxides is 1.12. Catalyst C 3 The contents of Mo, Ni and W are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com