A zinc oxide based blue LED and its manufacture method

A blue-light luminescent, zinc oxide-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the limitation of luminous efficiency, achieve the effects of reducing interface pollution, improving luminous efficiency, and reducing non-radiative recombination centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

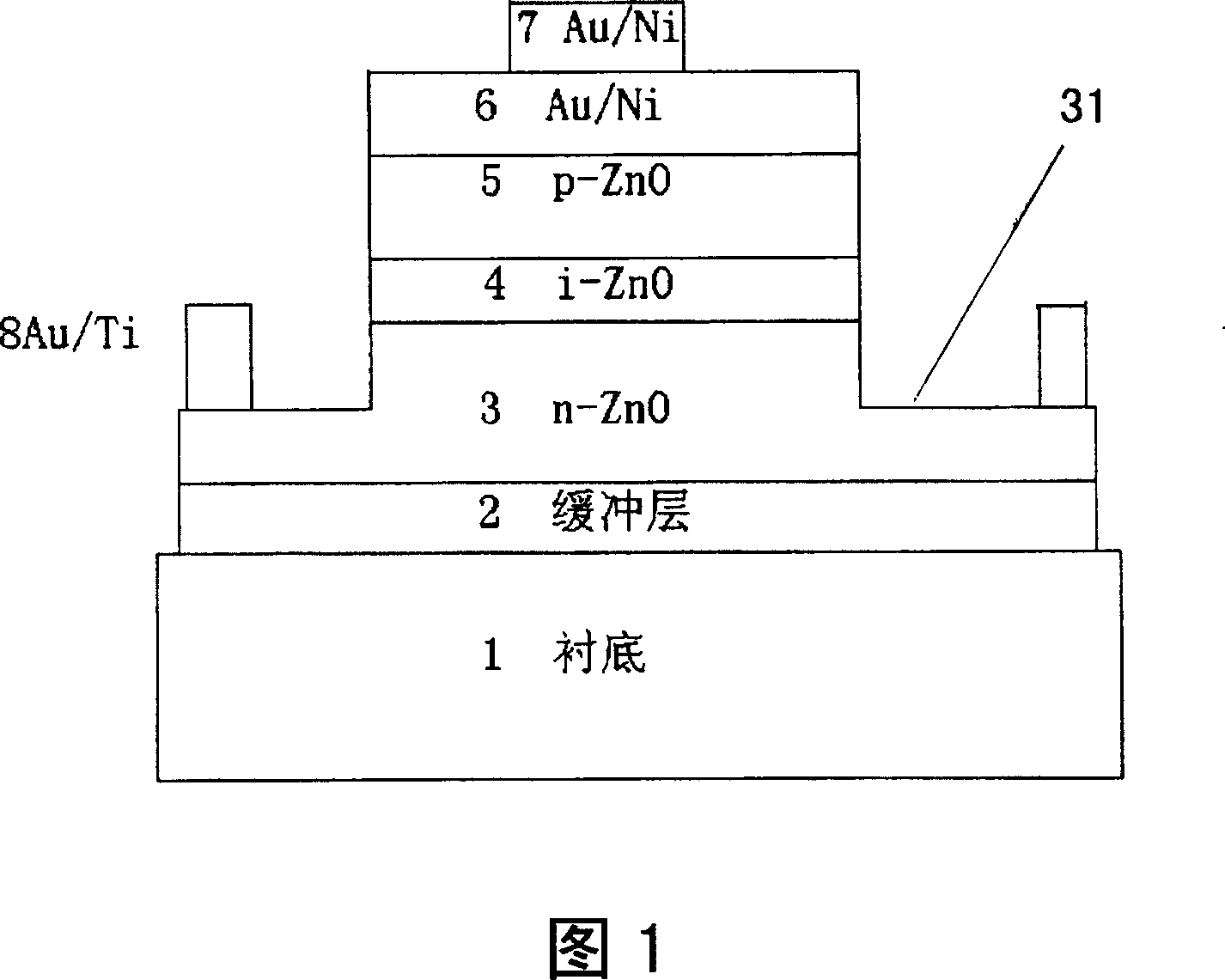

[0037] See also shown in Fig. 1, the present invention 1, a kind of zinc oxide-based blue light-emitting diode, is characterized in that, comprises:

[0038] A substrate 1, the substrate 1 is circular, and the substrate 1 is glass, silicon wafer, sapphire, zinc oxide or ScAlMgO 4 ;

[0039] A buffer layer 2, the buffer layer 2 is made on the substrate 1, and the buffer layer 2 is conducive to improving the quality of epitaxial growth of materials;

[0040] An n-zinc oxide layer 3, the n-zinc oxide layer 3 is made on the buffer layer 2, and an annular step 31 is etched on the edge of the n-zinc oxide layer 3, and the n-zinc oxide layer 3 is conducive to making a ring Gold / titanium electrode 8;

[0041] An i-zinc oxide active layer 4, the i-zinc oxide active layer 4 is fabricated on the n-zinc oxide layer 3, the main function of the i-zinc oxide active layer 4 is electron-hole recombination;

[0042] A p-zinc oxide layer 5, the p-zinc oxide layer 5 is made on the i-zinc oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com