Heat radiator

A technology of a heat sink and a heat sink, which is applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve the problems of inconvenient operation and laborious operation, and achieve the effect of convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

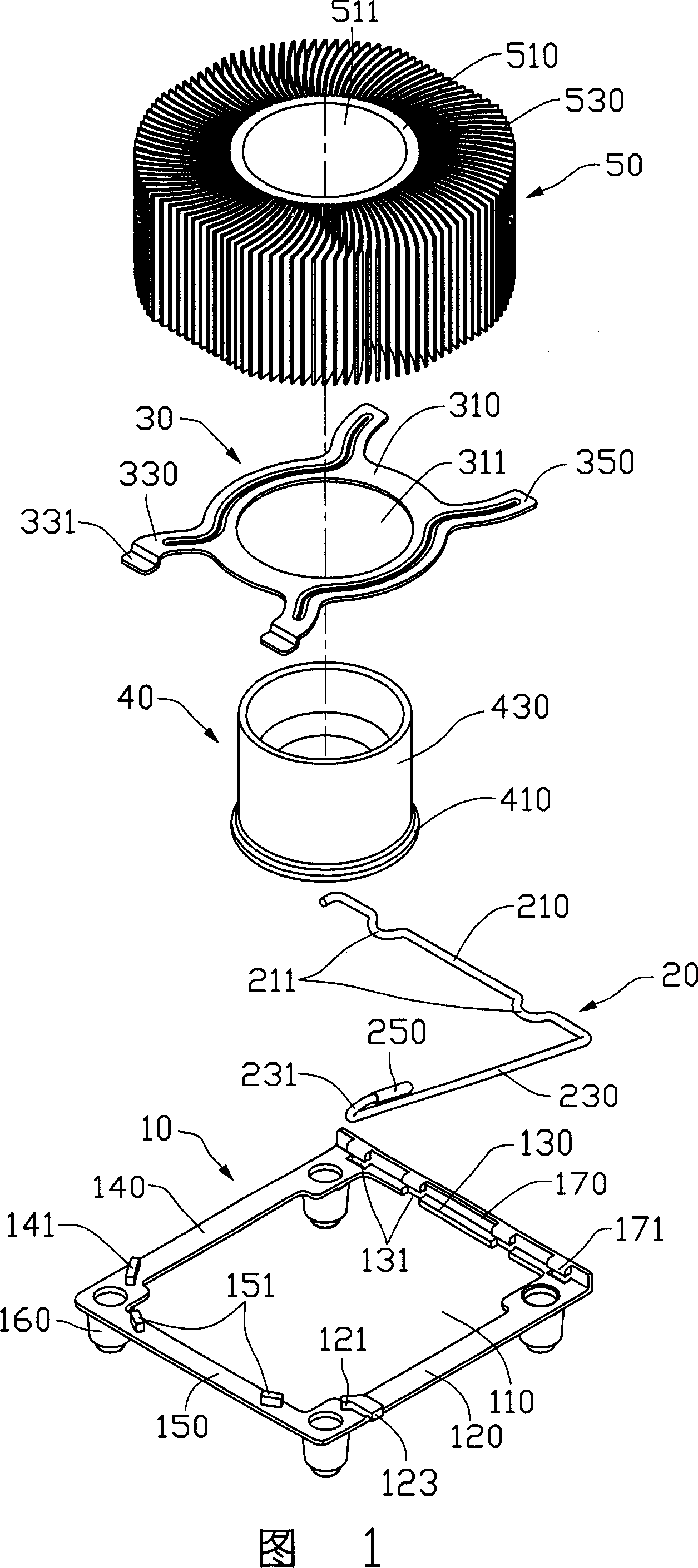

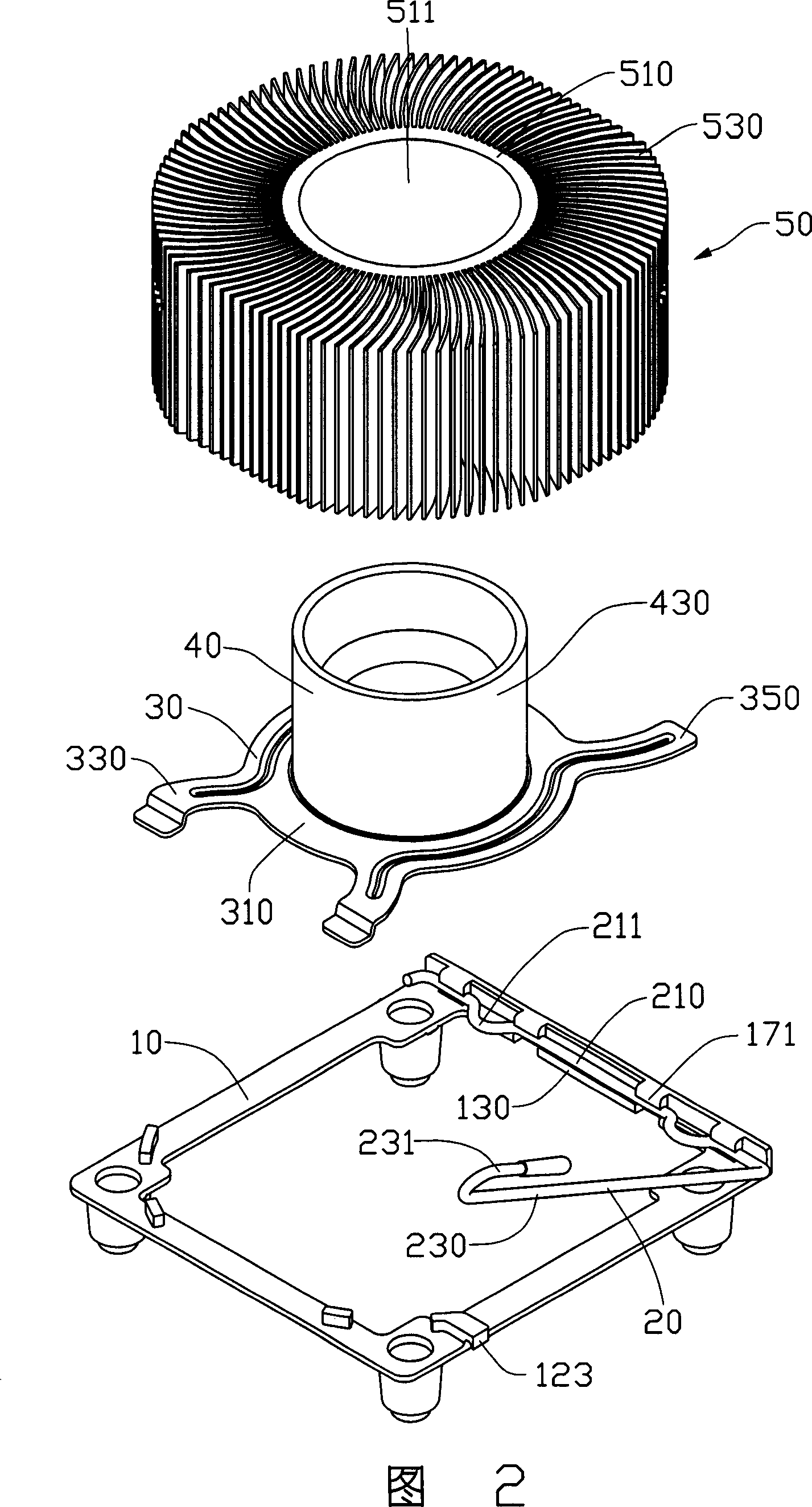

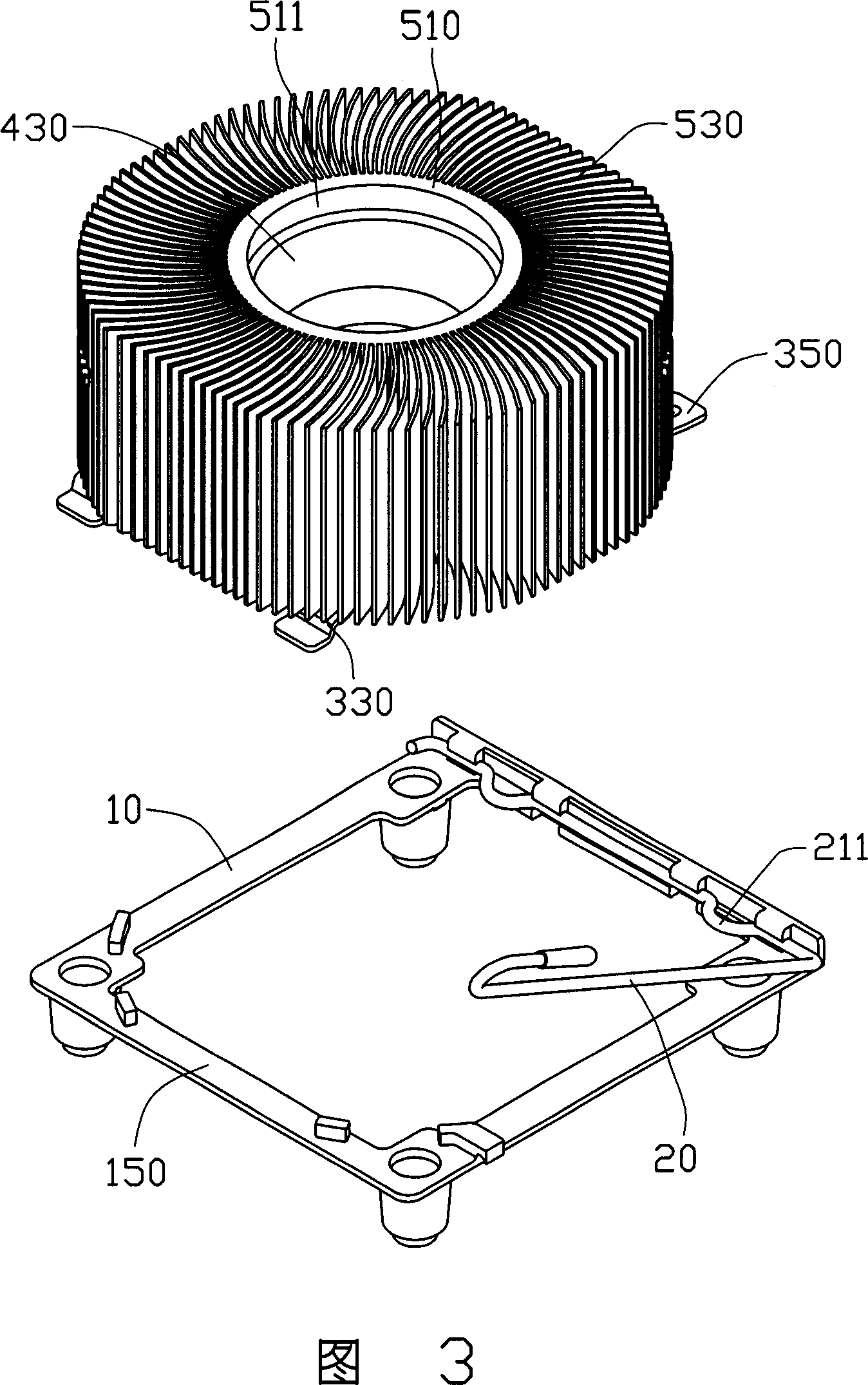

[0015] Please refer to FIG. 1 , the heat dissipation device is used for dissipating heat generated by an electronic component (not shown) mounted on a circuit board (not shown). The heat dissipation device includes a heat sink, and the heat sink includes a heat dissipation body 50 and a heat conductor 40 combined with the heat dissipation body 50 . The heat dissipation device further includes a fixing plate 30 matched with the heat conductor 40 , a buckle 20 and a fixing module 10 matched with the buckle 20 and the fixing plate 30 .

[0016] The fixing module 10 is a square frame, which is arranged on the circuit board around the electronic components. The fixing module 10 has an opening 110 for accommodating electronic components and first, second, third, and fourth sides 120 , 130 , 140 , and 150 surrounding the opening 110 . Four corners of the fixing module 10 extend downwards to define four fixing feet 160 for fixing the fixing module 10 to the circuit board. The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com