In-situ measuring apparatus for high temperature distortion ceramic fiber

A high-temperature deformation, in-situ measurement technology, applied in measuring devices, using optical devices, and applying stable tension/pressure to test the strength of materials, etc., can solve the problems of low test temperature and inaccurate strain measurement, and achieve strain measurement. Accurate, simple installation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

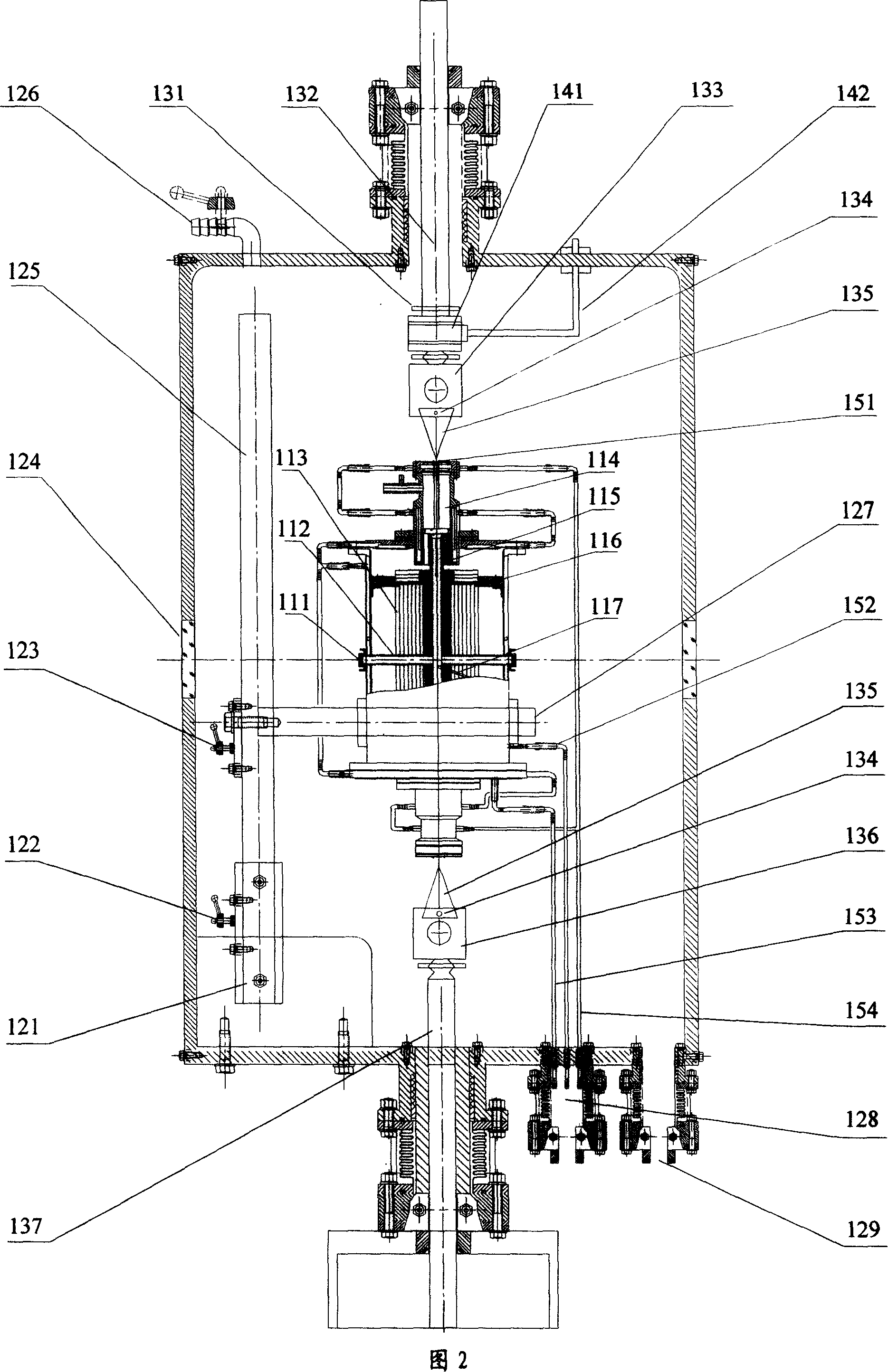

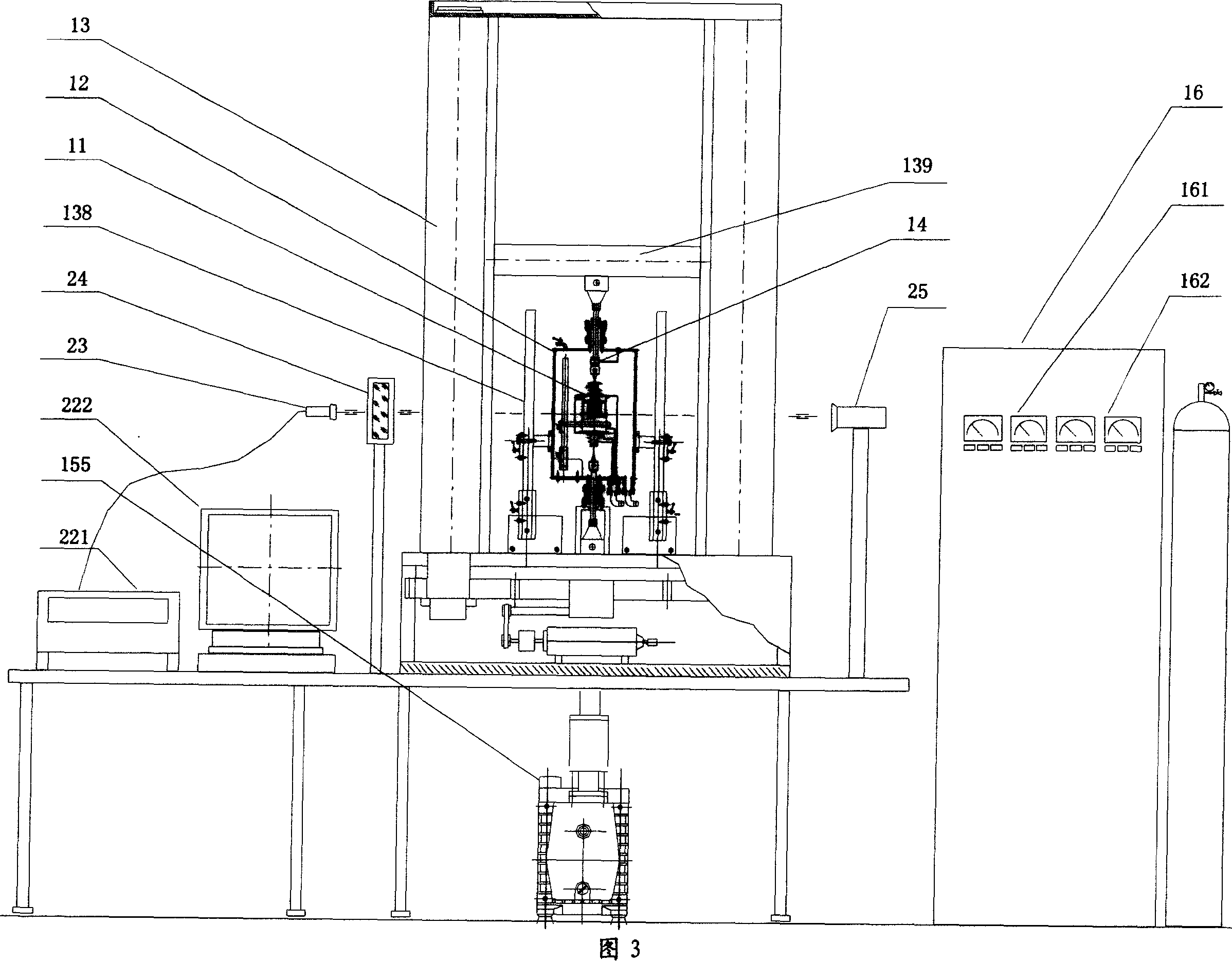

[0024] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

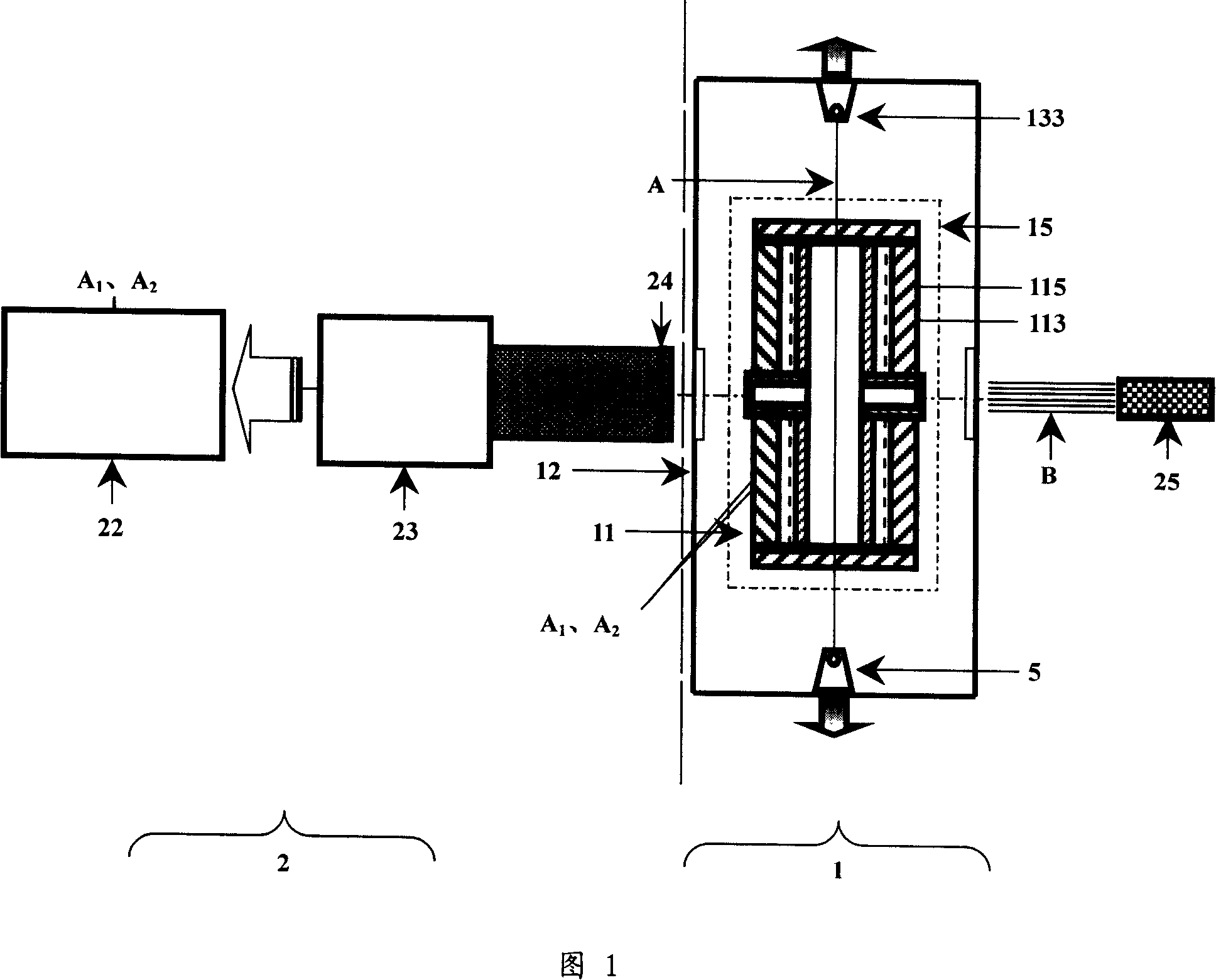

[0025] Referring to Figures 1-3, the in-situ measurement device for the deformation of ceramic fiber samples under high-temperature atmosphere protection consists of a high-temperature atmosphere furnace treatment system 1 and a high-precision optical measurement system 2.

[0026] The high-temperature atmosphere furnace processing system consists of a double furnace structure. The main function of the inner furnace 11 is to ensure high temperature, and the outer furnace 12 ensures the vacuum degree, which fully guarantees the vacuum degree and the airtightness of the inert gas. The inner furnace 11 and the outer furnace 12 are connected and fixed through the metal bracket 125 and the supporting metal ring 127. The two furnaces are placed in the middle of the universal testing machine 13 and fixed on the working platform of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com