Self-injection underwater perforating twist-sucking drilling machine

A penetrating and twisting suction technology, which is applied in the field of self-penetrating underwater drilling drills, can solve the problem of high cost, achieve the effects of avoiding use, reducing construction costs, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

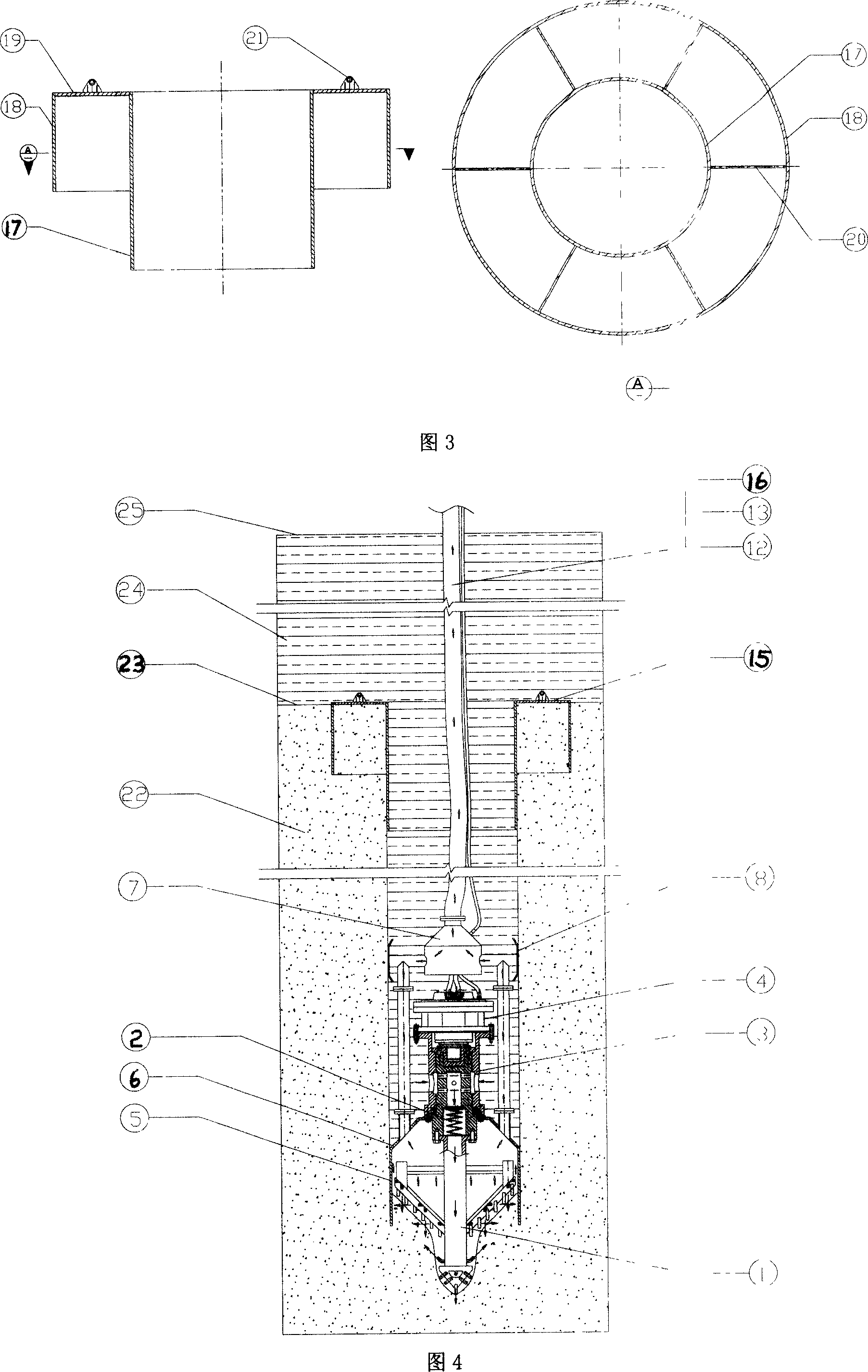

[0013] A self-penetrating underwater drilling cutter suction drilling rig, which is constructed from the following parts from bottom to top (see Figure 1)

[0014] The jet drill (1) includes a center drill and a drill frame: the center drill is hollow tubular, with a cutter plate and drill teeth at the lower end; the triangular structure welded to the drill frame and steel pipes provides sufficient rigidity, and is also a high-pressure water passage. The water nozzle, sprays high-pressure water flow when the drill bit is drilled. A low-pressure shut-off valve (2) is installed on the upper end of the jet drill bit (1), and its upper part is an over-current swivel head (3). Drill bit (1) is connected with flange. The rotating shaft of the over-current swivel head (3) is a hollow structure, with side holes in the middle and the upper end, its function is to transmit the rotational torque of the hydraulic motor (4) to the drill bit, and let the water outside the over-current swiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com