Bamboo residential building

A technology for residential construction and bamboo, which is applied in the direction of residential construction, architecture, building structure, etc., can solve the problems of long timber production period and other problems, and achieve the effects of short construction period, large output and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be further described in detail with reference to the drawings and specific embodiments.

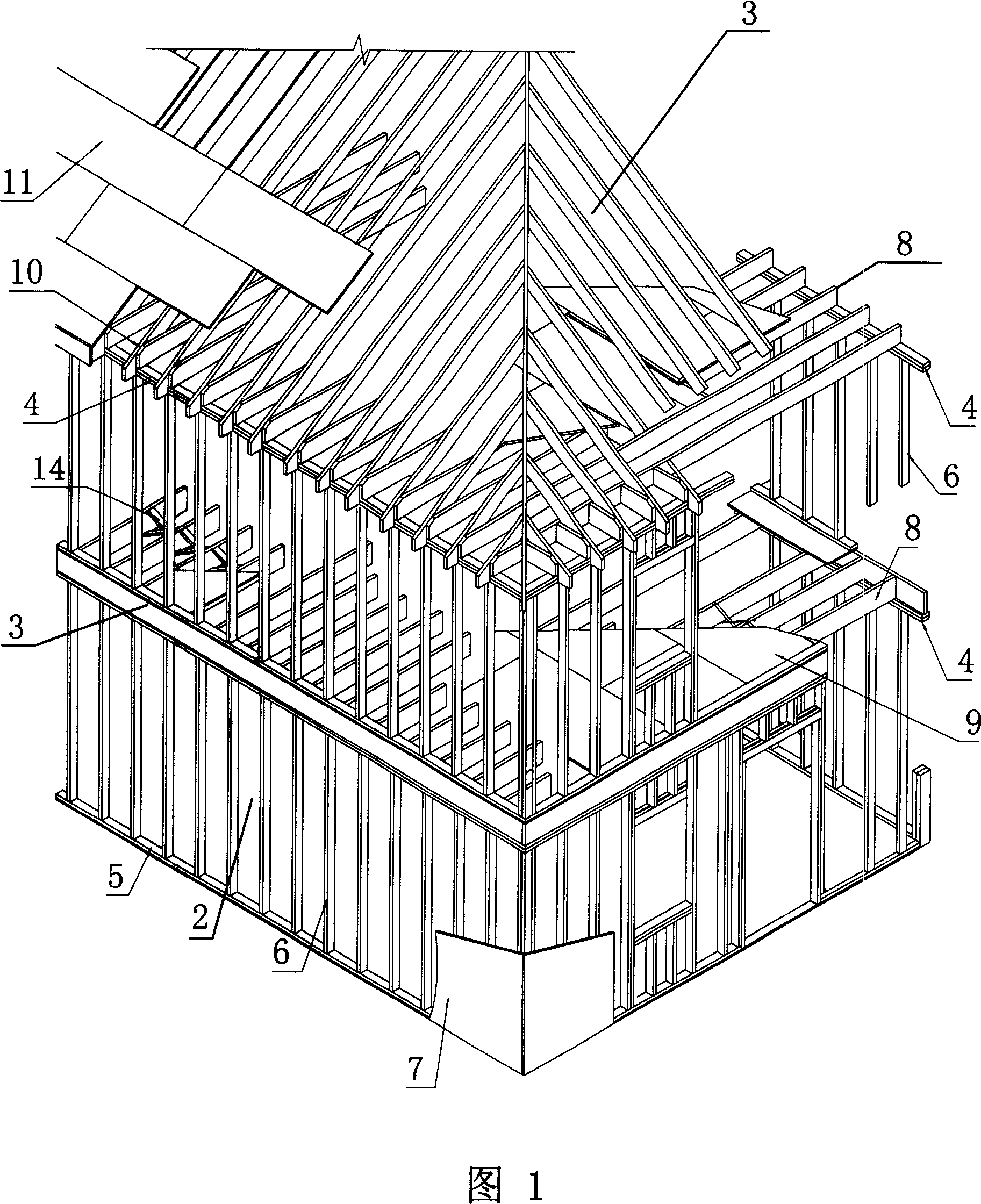

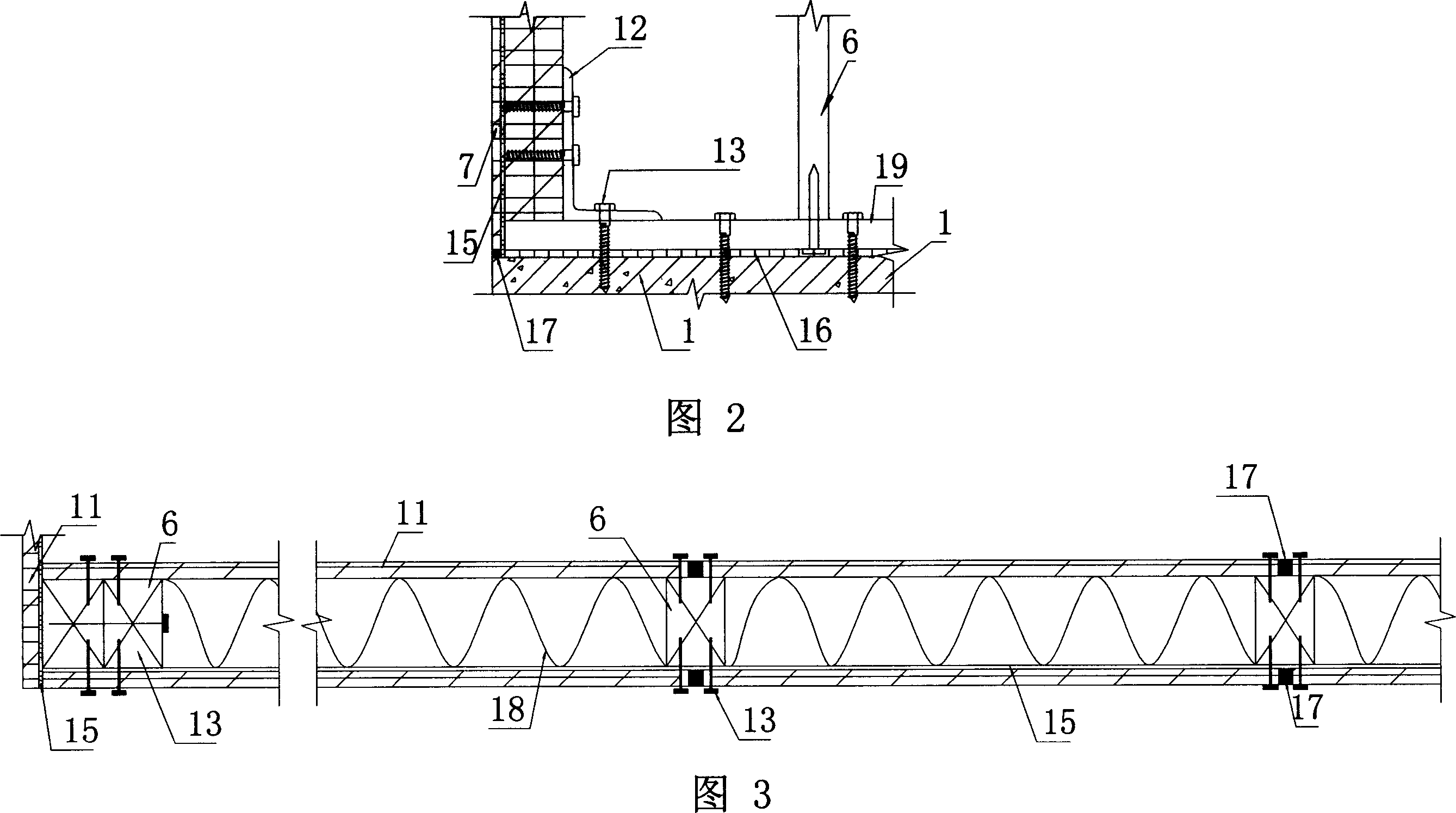

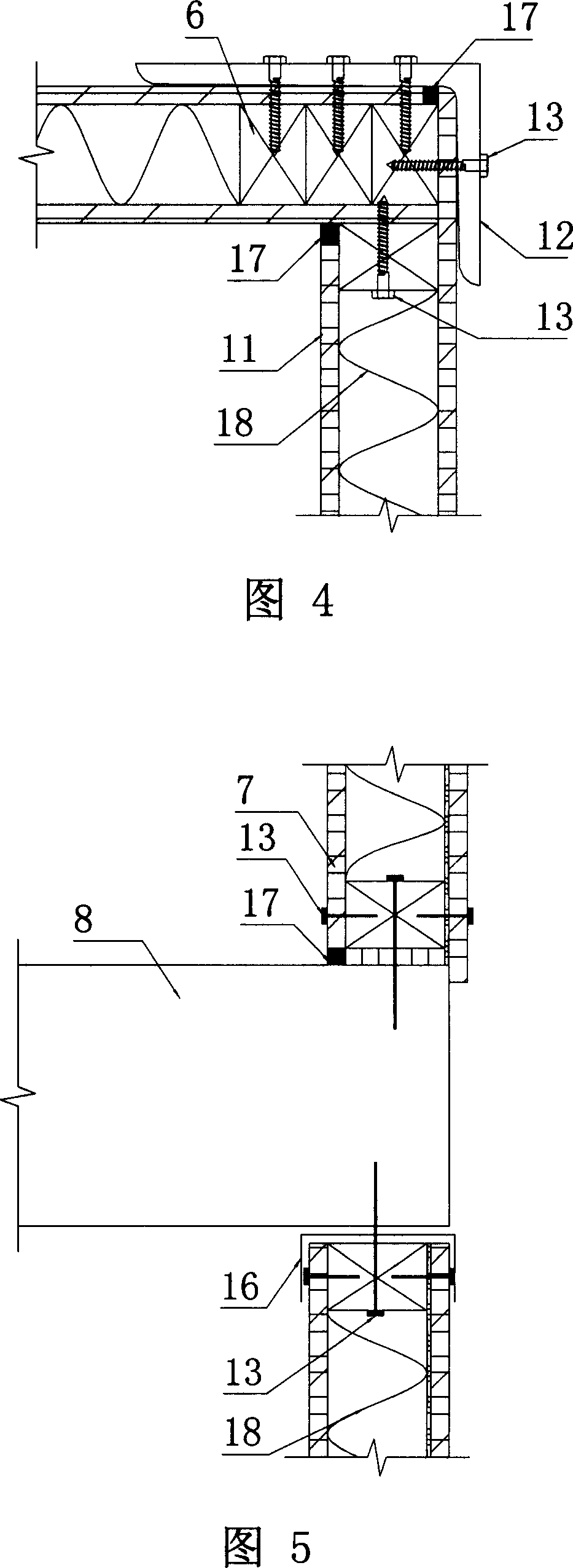

[0038] As shown in Figure 1, the bamboo residential building of the present invention includes a foundation 1, a wall 2, a floor cover 3, and a roof 20 in order from bottom to top. The connections between the various components adopt iron nails, screws, and cementing methods. Supplemented with special connectors and fiber reinforced plastic layer (FRP) to maintain integrity. Among them, the foundation 1 is a bamboo-reinforced concrete or reinforced concrete structure, and the wall 2 and the floor 3 are made of bamboo or bamboo-wood composite members. The main advantage is that the floor 3 and the wall 2 can be constructed separately, so the completed floor 3 can be used as a working platform during the construction of the upper wall 2, and the bamboo components can also be assembled in other places before being transported to the construction sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com