Method for reclaiming methylene chloride from waste gas

A dichloromethane and recovery method technology, which is applied in the field of recovery of dichloromethane in exhaust gas, can solve the problems of limiting the application of absorption recovery technology and high requirements on absorbent performance, and achieves small one-time investment, high recovery rate and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

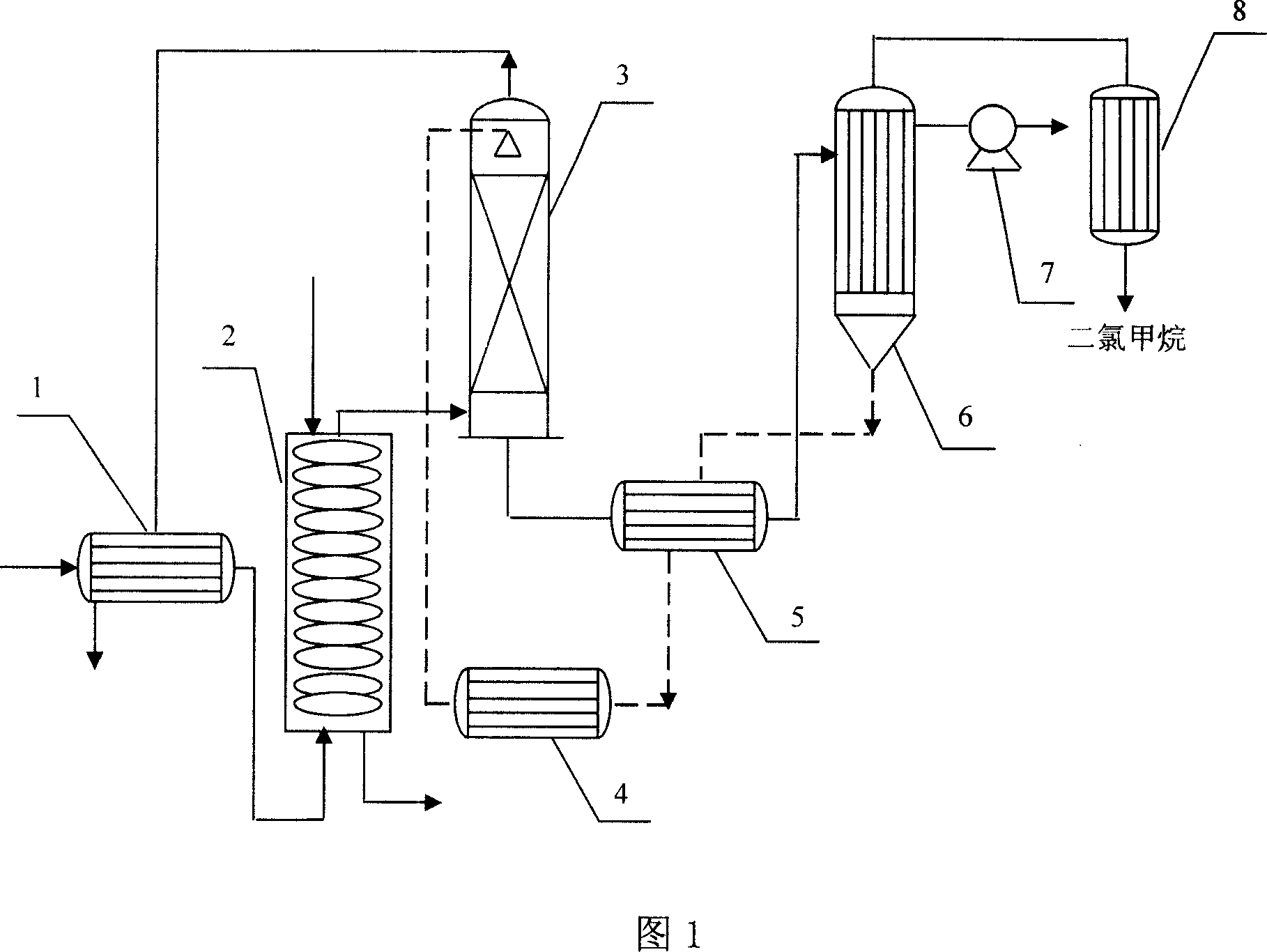

[0014] The invention proposes a method for recovering dichloromethane in waste gas. This recovery method adopts the combination method of condensation and absorption to recover the dichloromethane in the exhaust gas. First, water is used as the cooling medium to condense the exhaust gas, and then dimethylformamide is used as the absorbent in the packed absorption tower to remove dichloromethane in the exhaust gas. Chloromethane is absorbed, and the absorbent is heated and decomposed in the falling film evaporator under negative pressure conditions, so that the absorbent is regenerated to form a closed cycle. Among them, the absorbent should have greater solubility for the organic gas to be recovered, obvious selective absorption, low volatility, low viscosity, low pressure drop, non-corrosive, non-toxic, high conductivity, non-flammable, non-foaming, freezing point Low, cheap and easy to obtain, easy to desorb and regenerate, good chemical stability, etc. Fig. 1 is the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com