Forming method of part semiconductor assembly

A technology for semiconductors and components, which is applied in the field of forming some semiconductor components, can solve the problems of inconvenience and lack of suitable manufacturing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

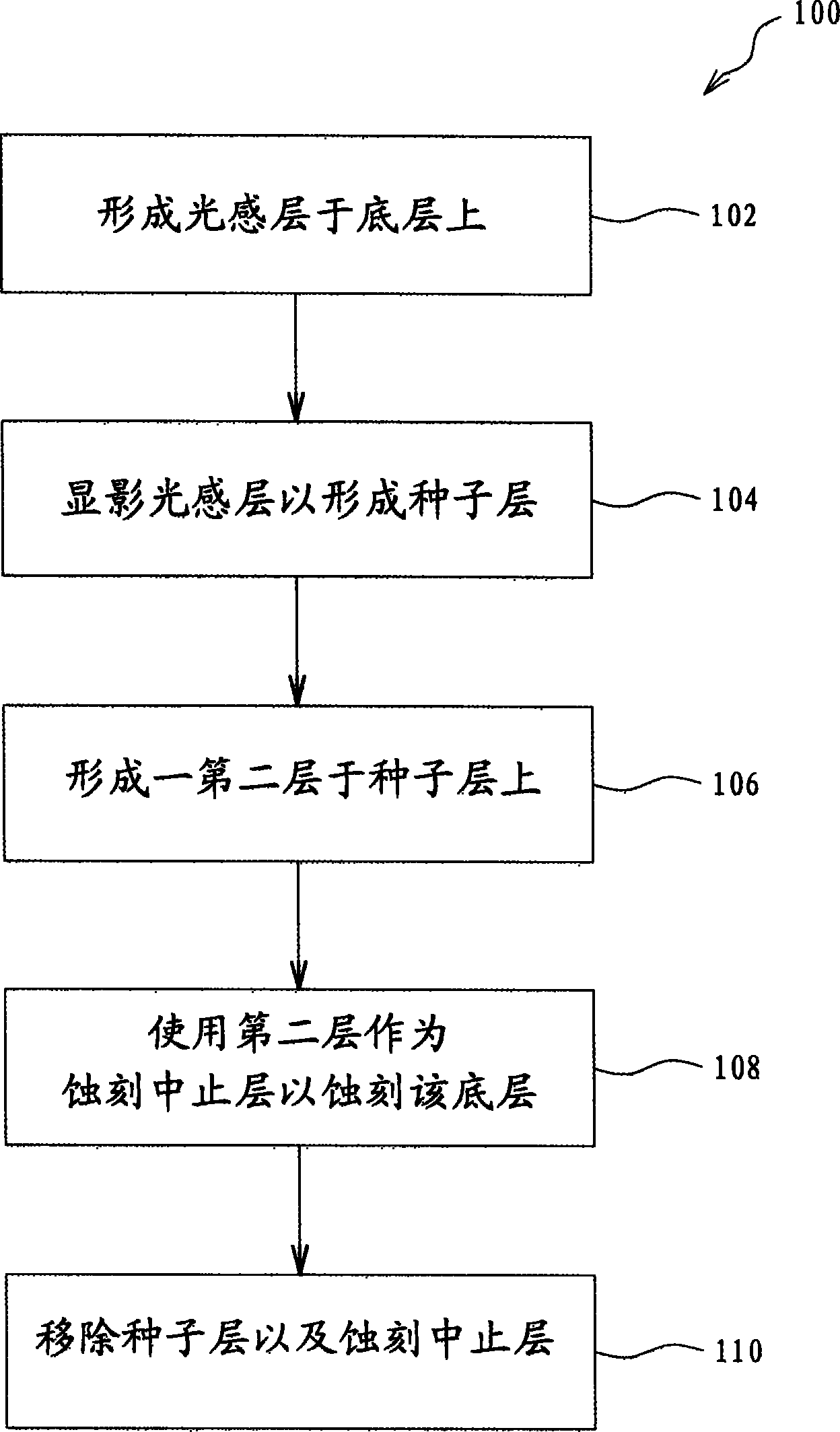

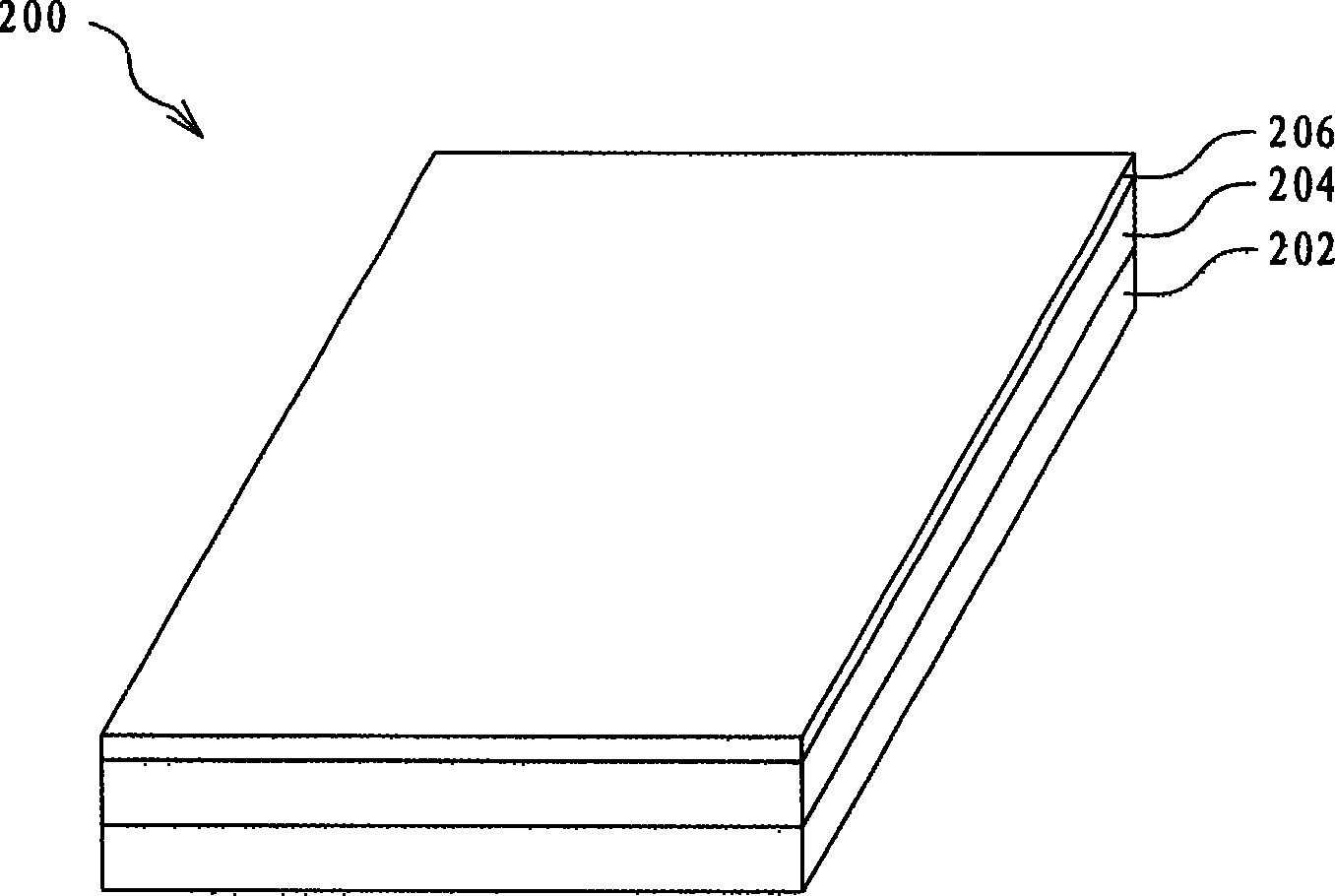

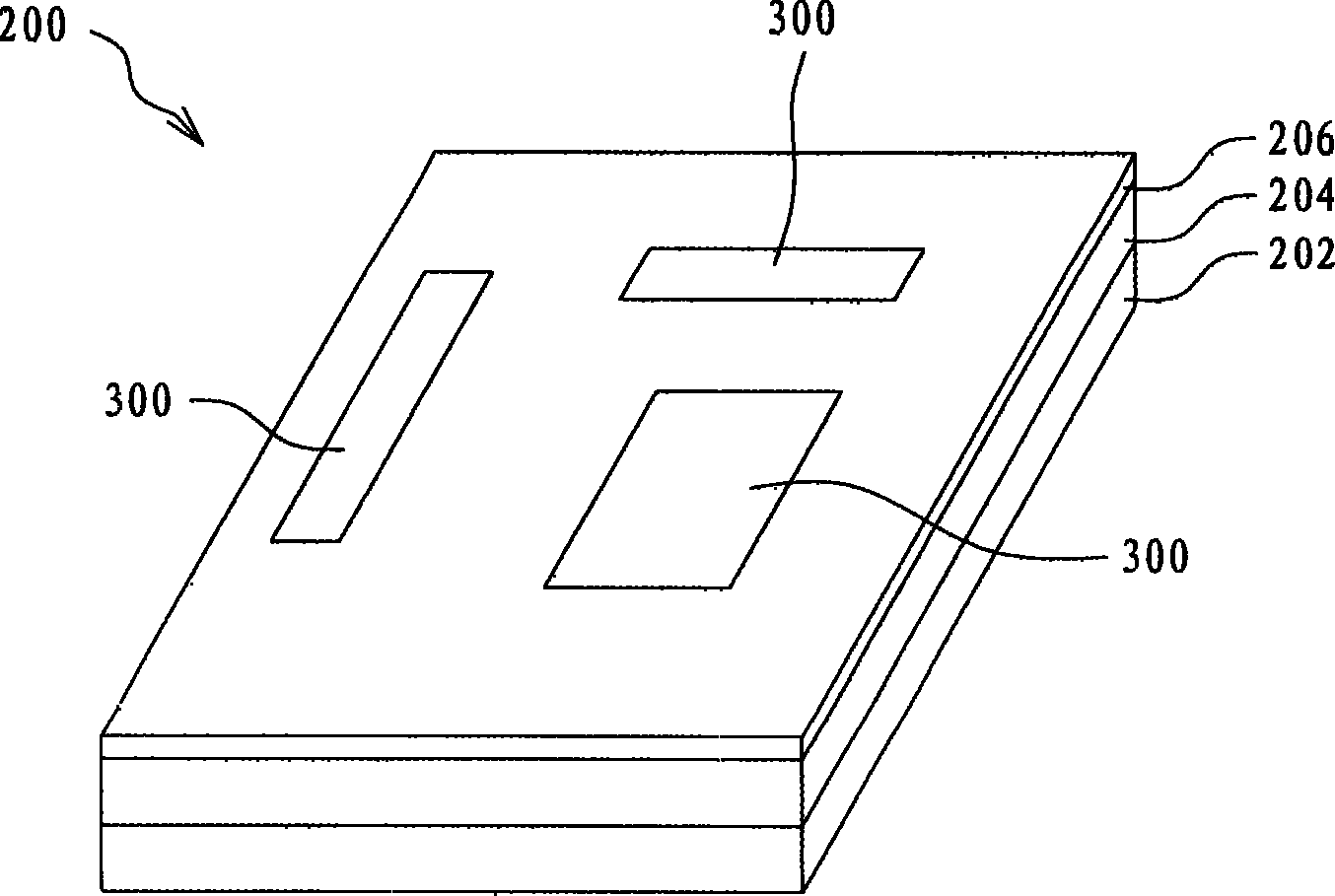

[0058] In order to further illustrate the technical means and effects that the present invention adopts for reaching the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, its specific implementation, method (manufacturing method) of the method for forming part of the semiconductor component proposed according to the present invention , processing method), steps, features and effects thereof, detailed descriptions are as follows.

[0059] The invention to be disclosed next provides many different embodiments, or examples, to illustrate different features of the invention. The following specific examples of constituent elements and arrangements will facilitate understanding of the present invention. Of course, these examples are not intended to limit the present invention. In addition, some reference numerals or nouns are repeated in various embodiments of the present invention, which is for the purpose of simplify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com