Field emission element in use for background light

A technology of emitting elements and field emission, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of high power consumption, energy reduction, and efficiency reduction, and achieve the goal of reducing power consumption, reducing possibility, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

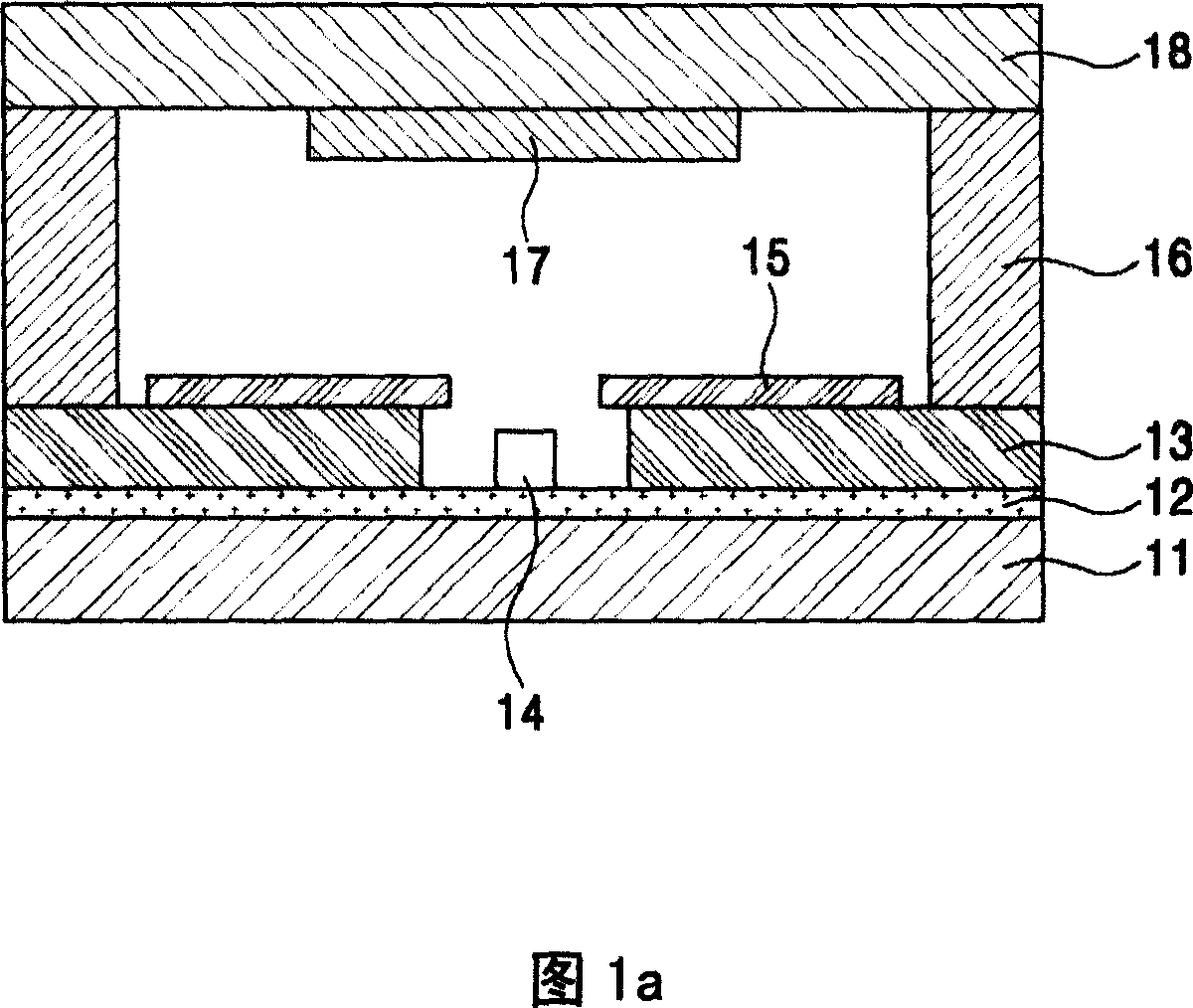

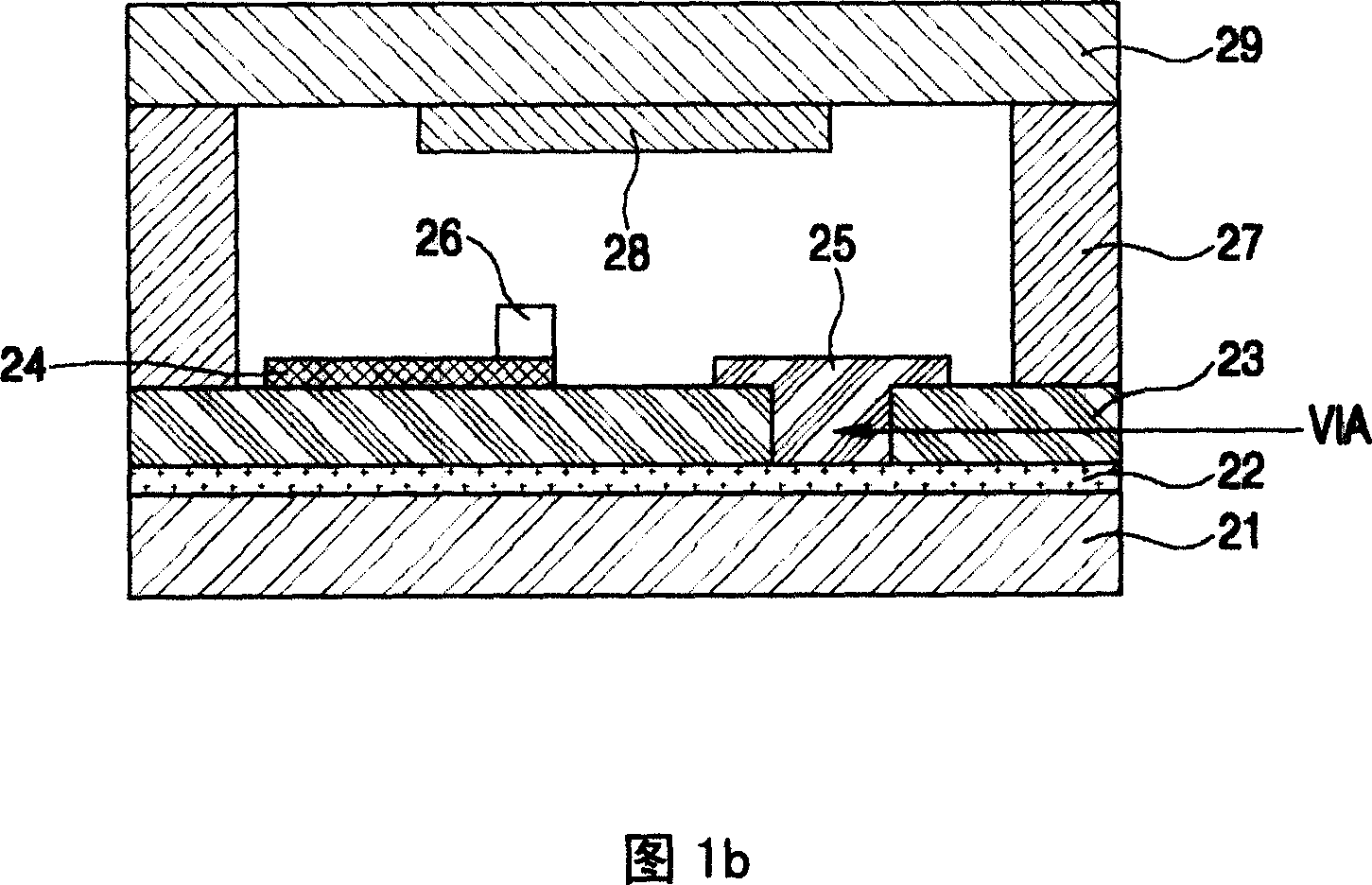

[0032] Below, the preferred embodiment of the field emission element for the backlight according to the present invention will be referred to the accompanying drawings.

[0033] Examples are described in detail.

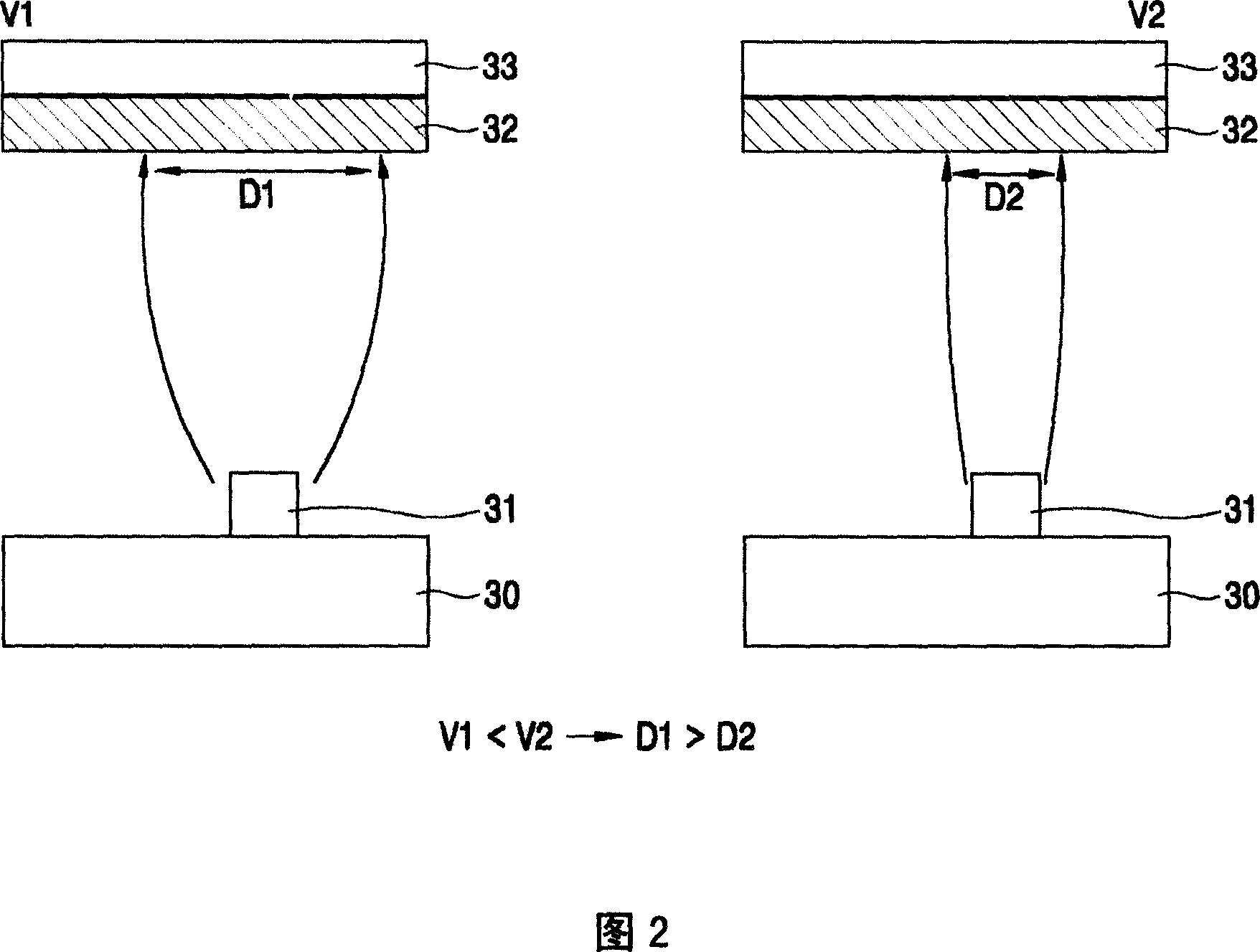

[0034] Generally speaking, the efficiency of the backlight is expressed by "efficiency=brightness×π×display area / power". It can be known from the formula that efficiency is directly proportional to brightness and display area, and inversely proportional to power.

[0035] The main features of the present invention are as follows: the shape of the fluorescent surface that collides with the electrons released from the carbon nanotube to emit light is a protruding surface structure, and the surface area of the fluorescent body that collides with the emitted electrons is enlarged.

[0036] Fig. 3 shows a cross-sectional view of a carbon nanotube field emission element with a counter electrode bottom gate structure for a background light according to the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com