Atomizing nozzle

A technology of atomizing nozzles and injection ports, which is applied in the direction of spraying devices, spraying devices, etc., can solve problems such as unsatisfactory atomization effects, and achieve the effects of improving atomization effects, increasing the collision area, and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

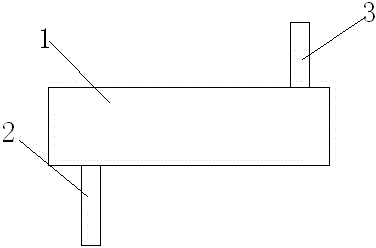

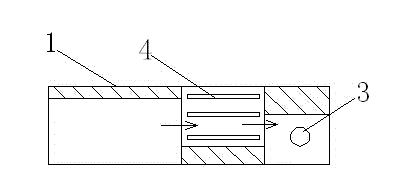

[0012] The present invention comprises a gas-liquid mixing chamber 1, one end of the gas-liquid mixing chamber 1 is provided with a liquid inlet 2, and the other end is provided with an injection port 3 which is axially offset from the liquid inlet 2;

[0013] The channel of the gas-liquid mixing chamber 1 has protruding ribs 4 .

[0014] The channel of the gas-liquid mixing chamber 1 becomes smaller and smaller along the direction from the liquid inlet 2 to the injection port 3 .

[0015] The convex line 4 of the present invention is arranged parallel to the axis of the gas-liquid mixing chamber 1, so as to avoid the pressure loss caused by the excessive resistance to the conveying medium caused by the vertical arrangement of the convex line 4 and the axial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com