Air-cooling thin oil lubricant solid bowl type bearing structure with bearing collar without water

A technology of thin oil lubrication and water strips, which is applied in the fields of hydropower generation, greenhouse gas reduction, climate sustainability, etc., can solve problems such as complex design of hydraulic turbine bearings, oil mist splashing in the oil circulation system, unfavorable installation and maintenance, etc., to achieve No oil mist splash, reliable oil circulation system and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

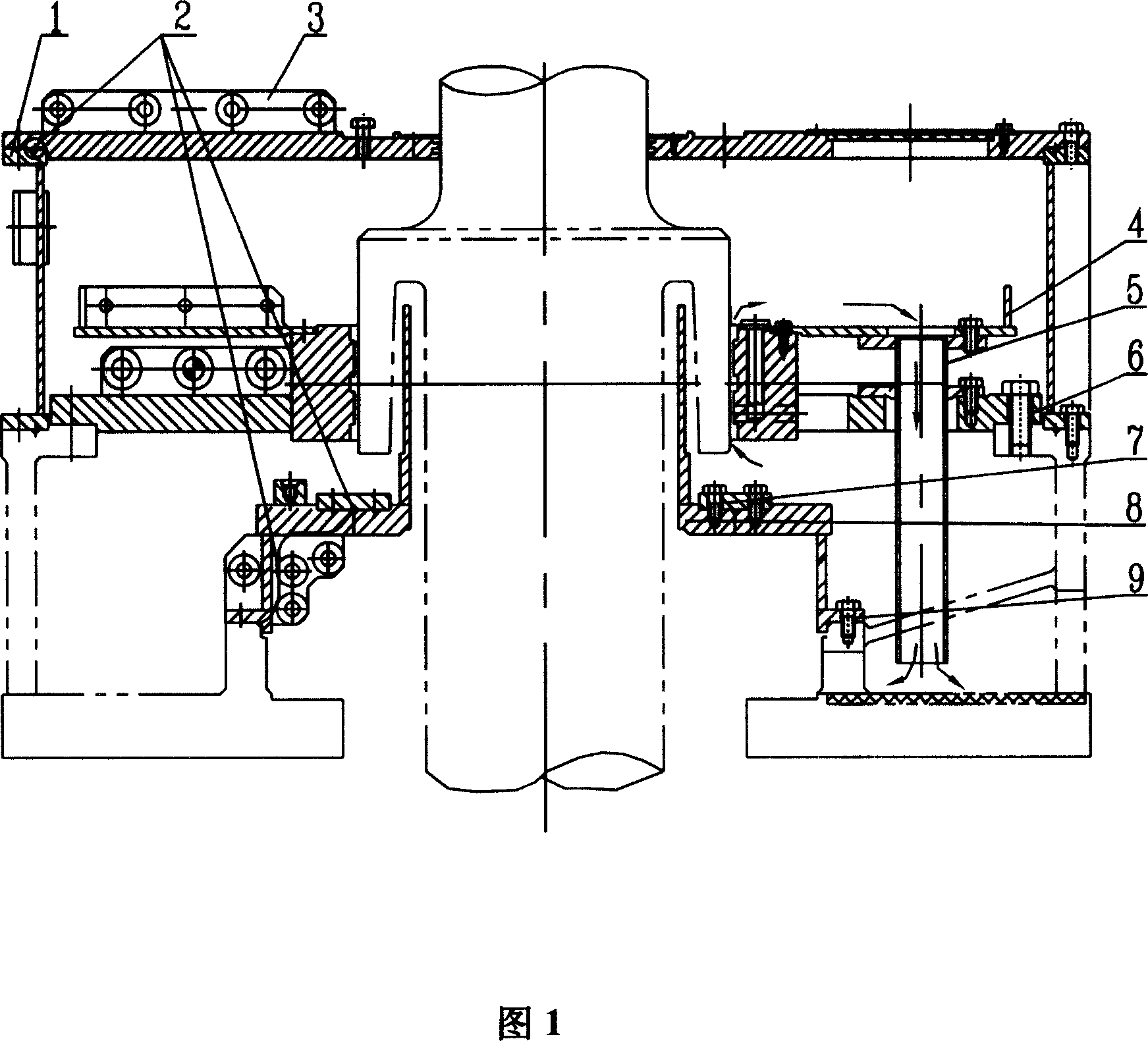

[0009] The present invention will be further described below in conjunction with the accompanying drawings: as shown in Figure 1, an air-cooled anhydrous thin oil lubricated cylindrical bearing structure with a shaft collar, which includes an upper oil tank 1, a bearing cover 3, an oil passing plate 4, a bearing body 6, a return Oil pipe 5, support cover 9, oil retaining cylinder 8 and signal monitoring device, bearing body 6 is a bearing body poured with babbitt alloy tiles. The lower oil tank is composed of the top cover 10, the seal 2, the bearing body 6, the pressure plate 7, the oil retaining cylinder 8, the support cover 9 and the corresponding connectors, through the external air cooling of the top cover and the formation between the bottom of the top cover and the runner The seal between the upper crown of the runner and the top cover in the annular cavity cools the top cover, thereby reducing the oil temperature. Some cooling fins are arranged on the top cover as part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com