Packing box for glass base plates, and packed composition

A glass substrate and packaging box technology, applied in packaging, transportation and packaging, packaging of vulnerable items, etc., can solve problems such as low safety factor and glass substrate damage, and achieve the effect of saving cost, reducing stress concentration and improving safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

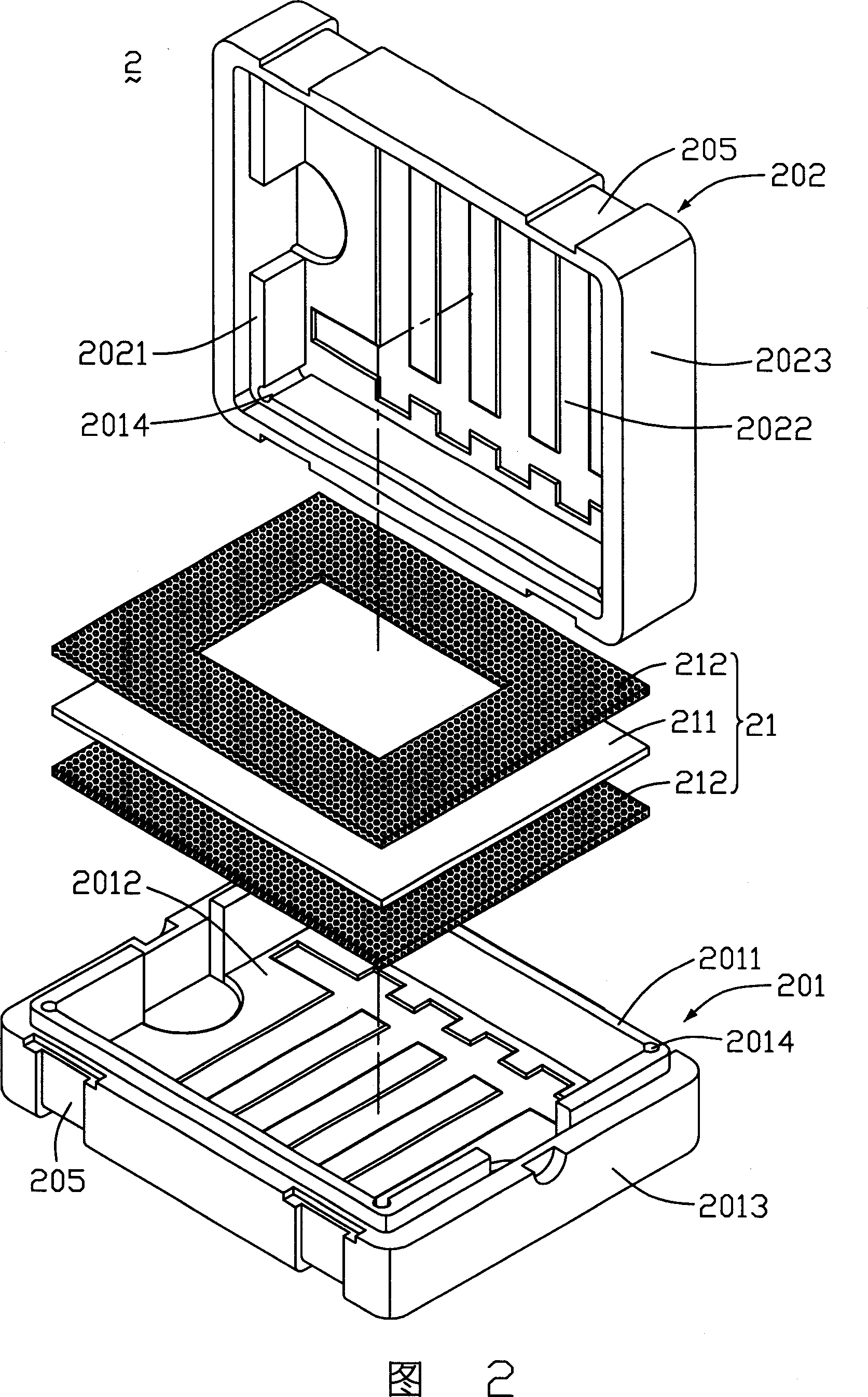

[0030] Please refer to FIG. 2 , which is a three-dimensional exploded schematic diagram of a packaging combination of a glass substrate disclosed in a preferred embodiment. This exploded view expresses the main structure of the packaging combination in the least amount. The packaging combination 2 includes a composite body 21 and a packaging box 20 (see FIG. 3 ). The composite body 21 includes two spacers 212 and a glass substrate 211 stacked on top of each other. The packaging box 20 includes a box body 201 and a cover body 202 , the box body 201 and the cover body 202 fit and nest together to form a receiving space. The stacked body 21 is accommodated in the accommodation space formed by the box body 201 and the cover body 202 .

[0031] The box body 201 of the packaging box 20 is a box body with a bottom, and the box body 201 includes four inner walls 2011 , a bottom 2012 and four outer walls 2013 . The four outer walls 2013 are respectively perpendicular to the bottom 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com