Filter device

A filter device and filter element technology, which is applied in filtration and separation, membrane filter, mobile filter element filter, etc., can solve the problems of pollution and waste water purification reaction, and achieve the effect of simple support and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

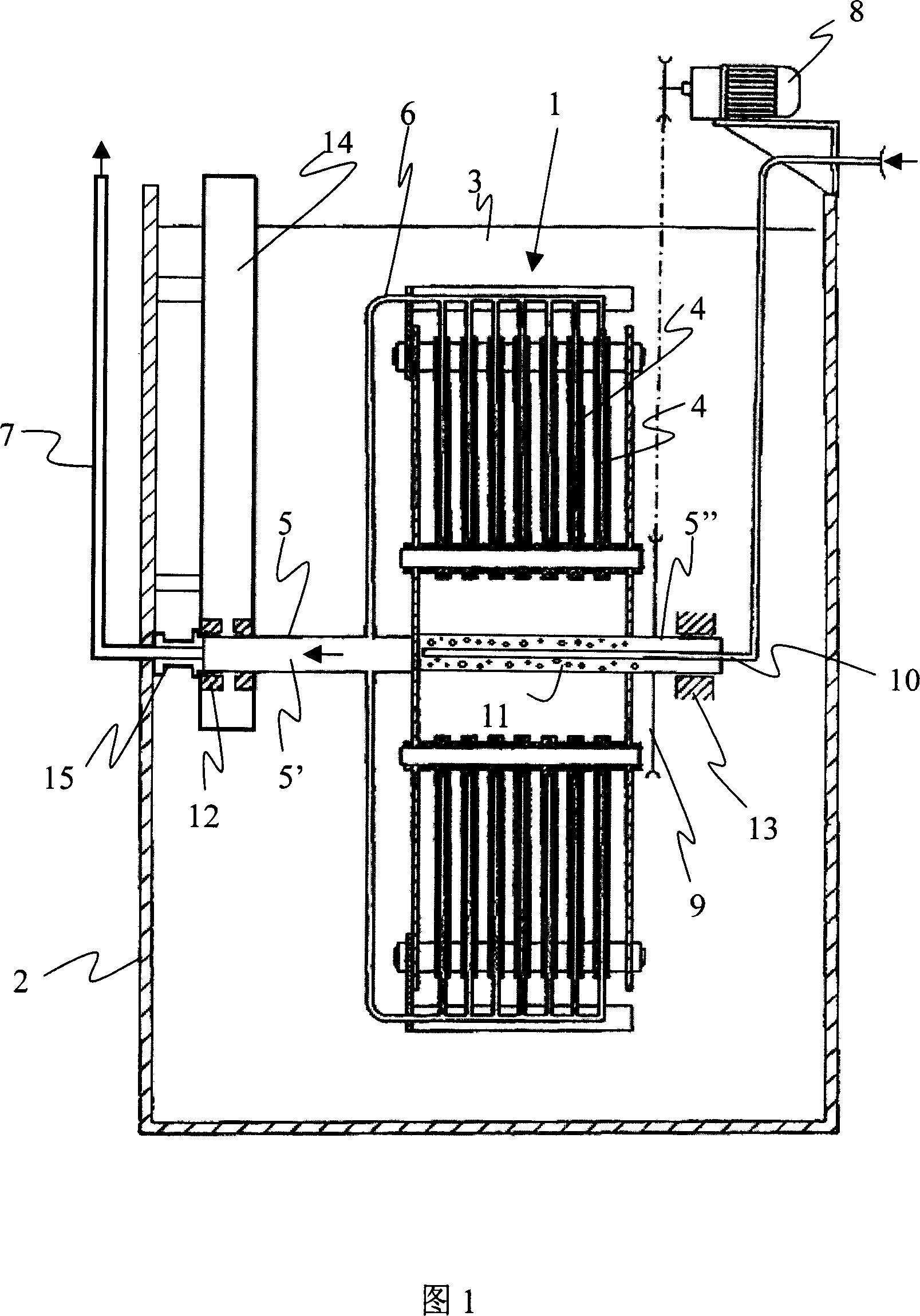

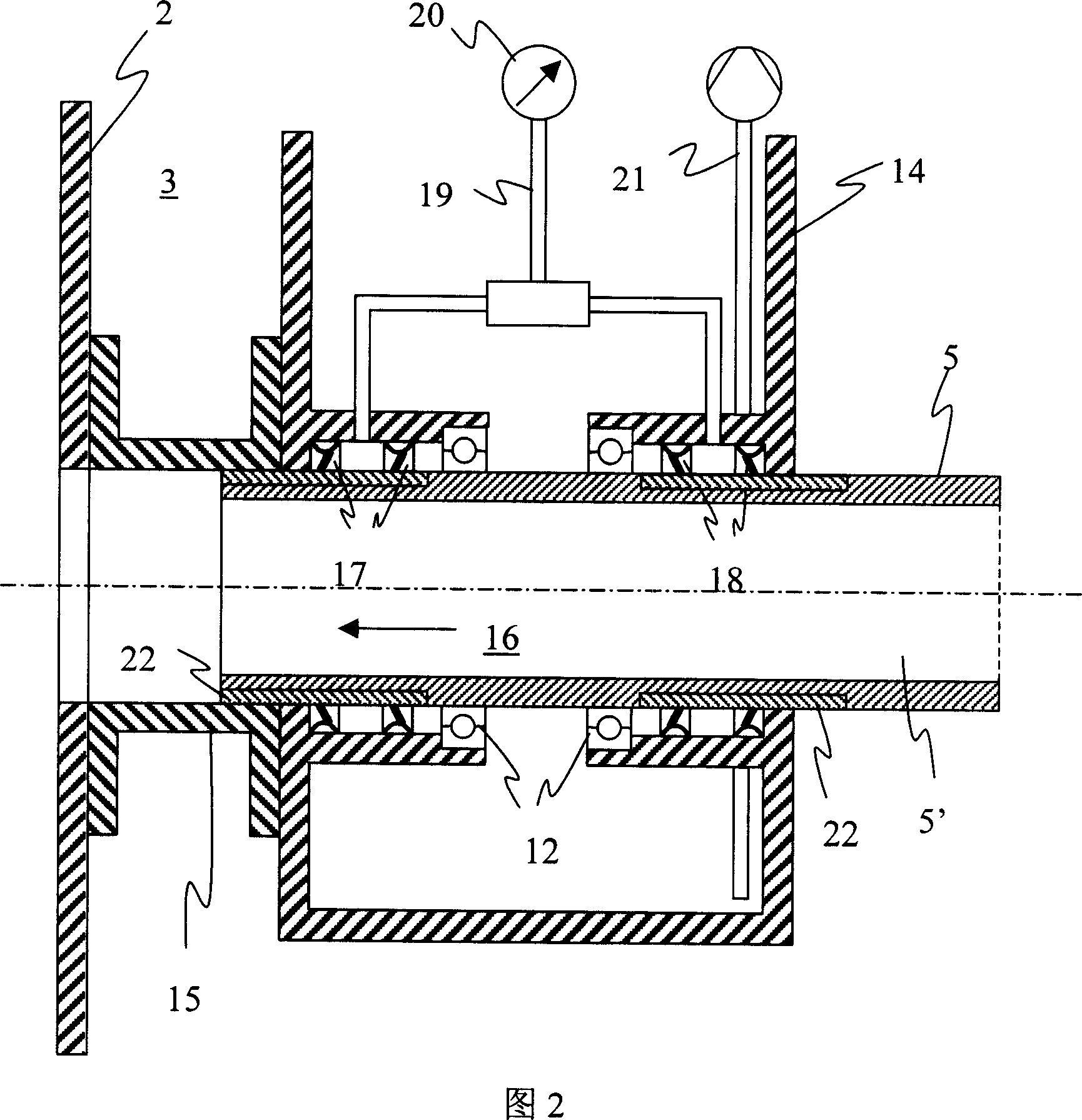

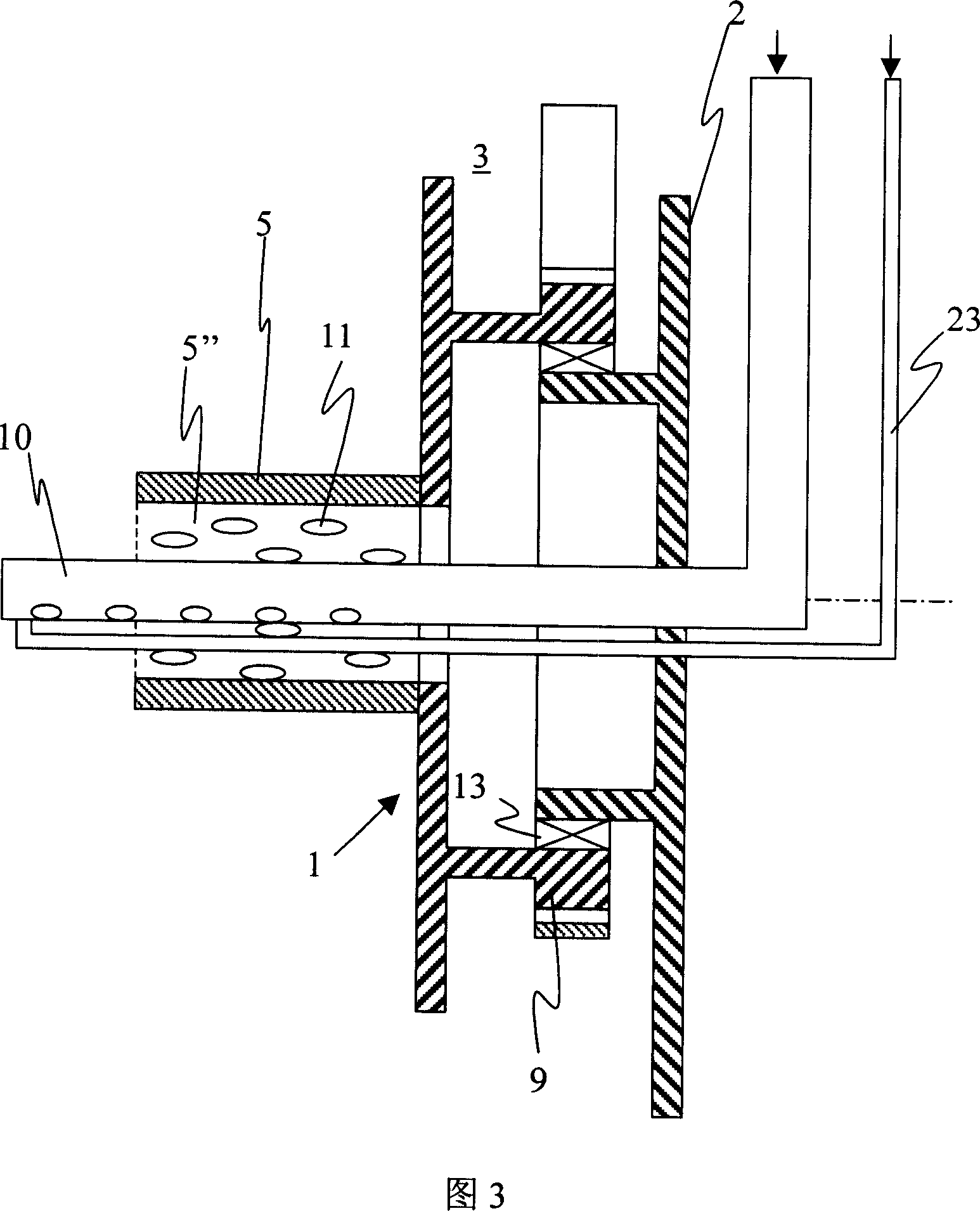

[0028] FIG. 1 shows a filter device 1 inside a container 2 containing raw liquid, in particular waste water 3 . The filter device 1 consists of several filter elements 4 arranged at intervals in a circle or polygon on a rotatably mounted hollow shaft 5 . The waste water 3 rests on the outside of the filter element 4 and is sucked through the filter element 4 into the supply line 6 . The supply line 6 leads to the hollow shaft 5 and from there is conveyed to the stationary duct 7 for removal from the container 2 .

[0029]The hollow shaft 5 together with the filter device 1 is driven by a drive motor 8 , in this example with a chain drive, which acts on a transmission gear 9 of the hollow shaft. A lance 10 through which a flushing medium, for example flushing gas or flushing liquid, is introduced is introduced into the interior of the hollow shaft 5 . The hollow shaft 5 is provided with several holes 11 in the area of the lance 10, through which the flushing medium of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com