Device and method for conditioning and monitoring of a saw blade

A technology of saw blade and guide device, which can be used in attachment devices of sawing machines, fine working devices, metal sawing equipment, etc., and can solve complex and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

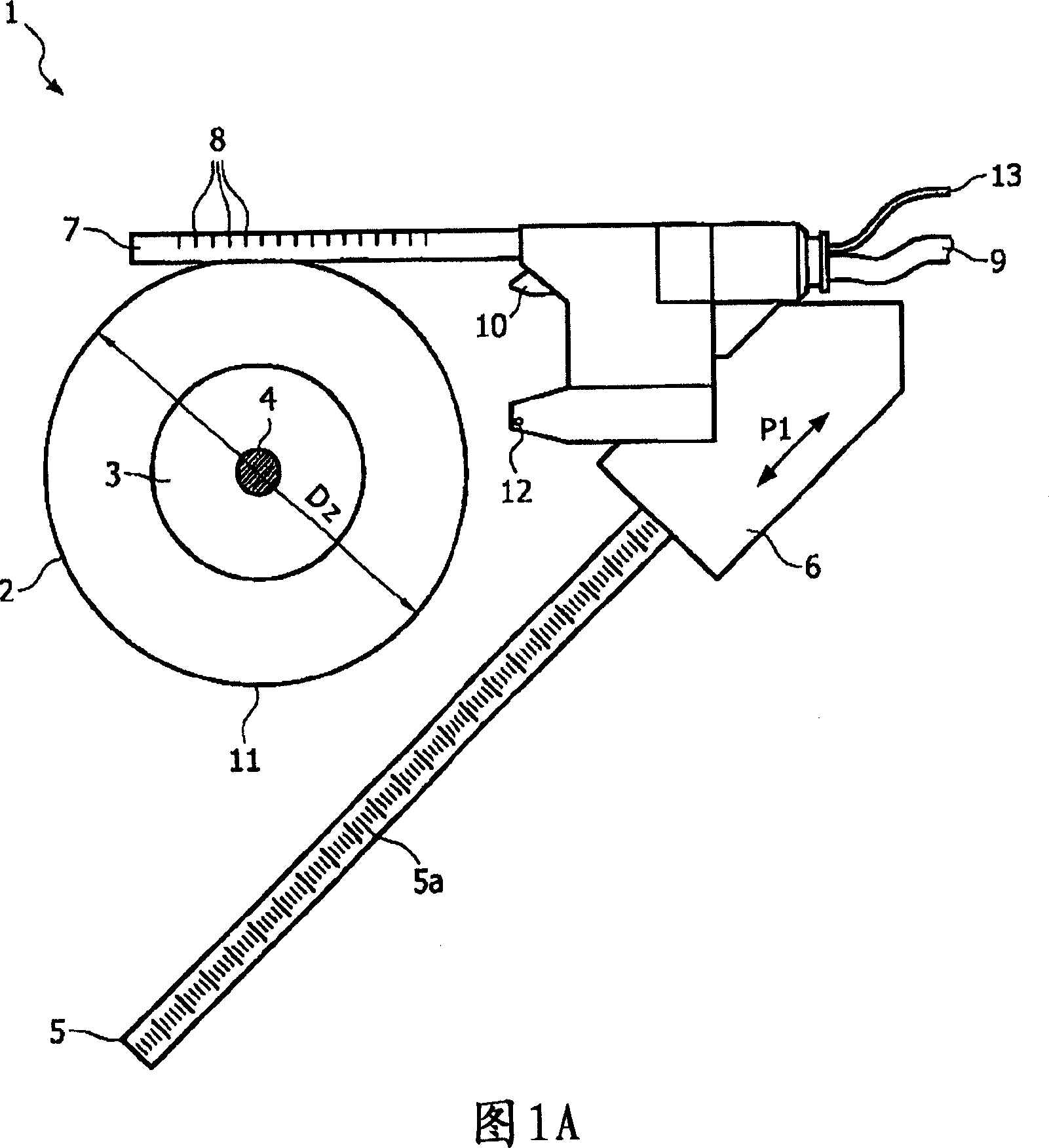

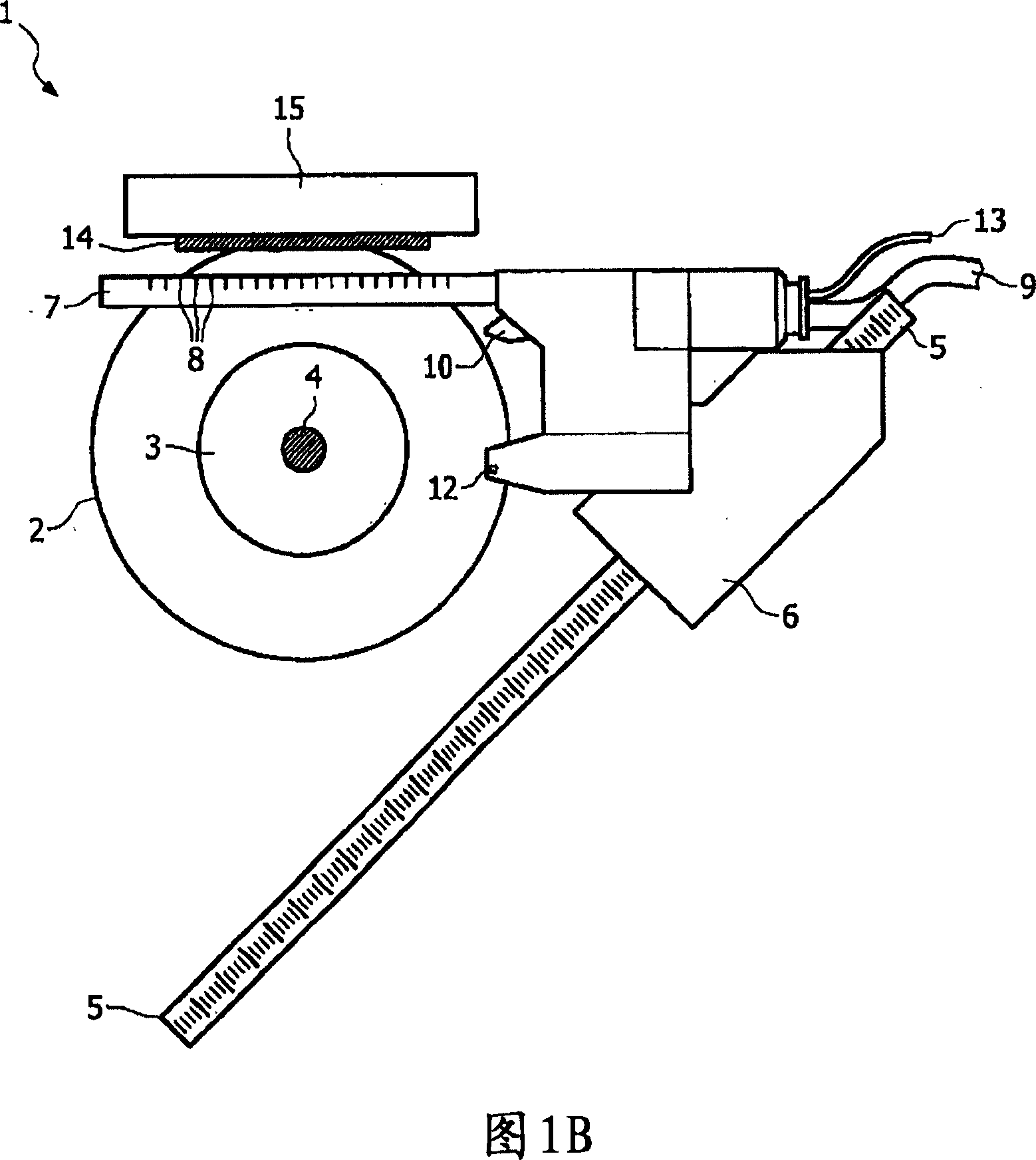

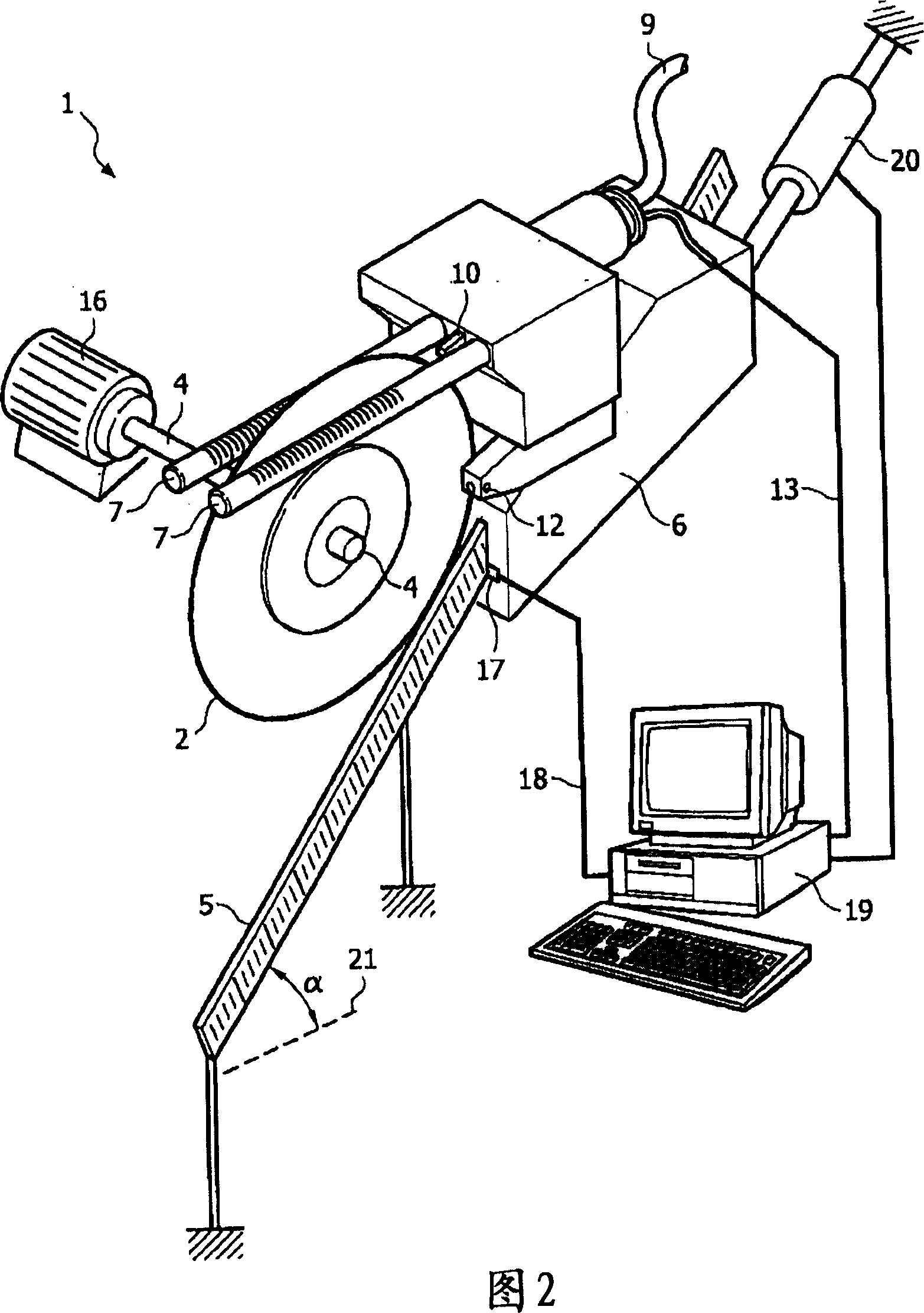

[0017] FIG. 1 shows a device 1 with a saw blade 2 for separating electronic components (not shown in this figure). The saw blade 2 is rigidly connected to a rotating drive shaft 4 with a mounting flange 3 . Located in a fixed position relative to the drive shaft 4 is a guide 5 along which the support frame 6 is movable according to the arrow P1. The support frame 6 carries a tube 7 with a slit 8 from which the liquid provided by the supply tube 9 can be sprayed. The liquid provided by the pipe 8 is used in particular to remove sawdust, as will be further elucidated in the following figures. The support frame also carries nozzles 10 from which the liquid supplied by the supply pipe 9 can also be sprayed. Alternatively, it is also possible that a separate supply for the nozzle 10 (ie separate from the supply 9 for the pipe 8 ) is connected to the device 1 . The nozzle 10 serves in particular to spray a liquid onto the circular cutting edge 11 of the saw blade 2 . The support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com