Low frequency angle vibration table

An angular vibration table, low frequency technology, used in measuring devices, instruments, speed/acceleration/shock measurement, etc., can solve the problems of narrow frequency response range, low measurement accuracy and resolution, and achieve high motion performance and signal quality. Good, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

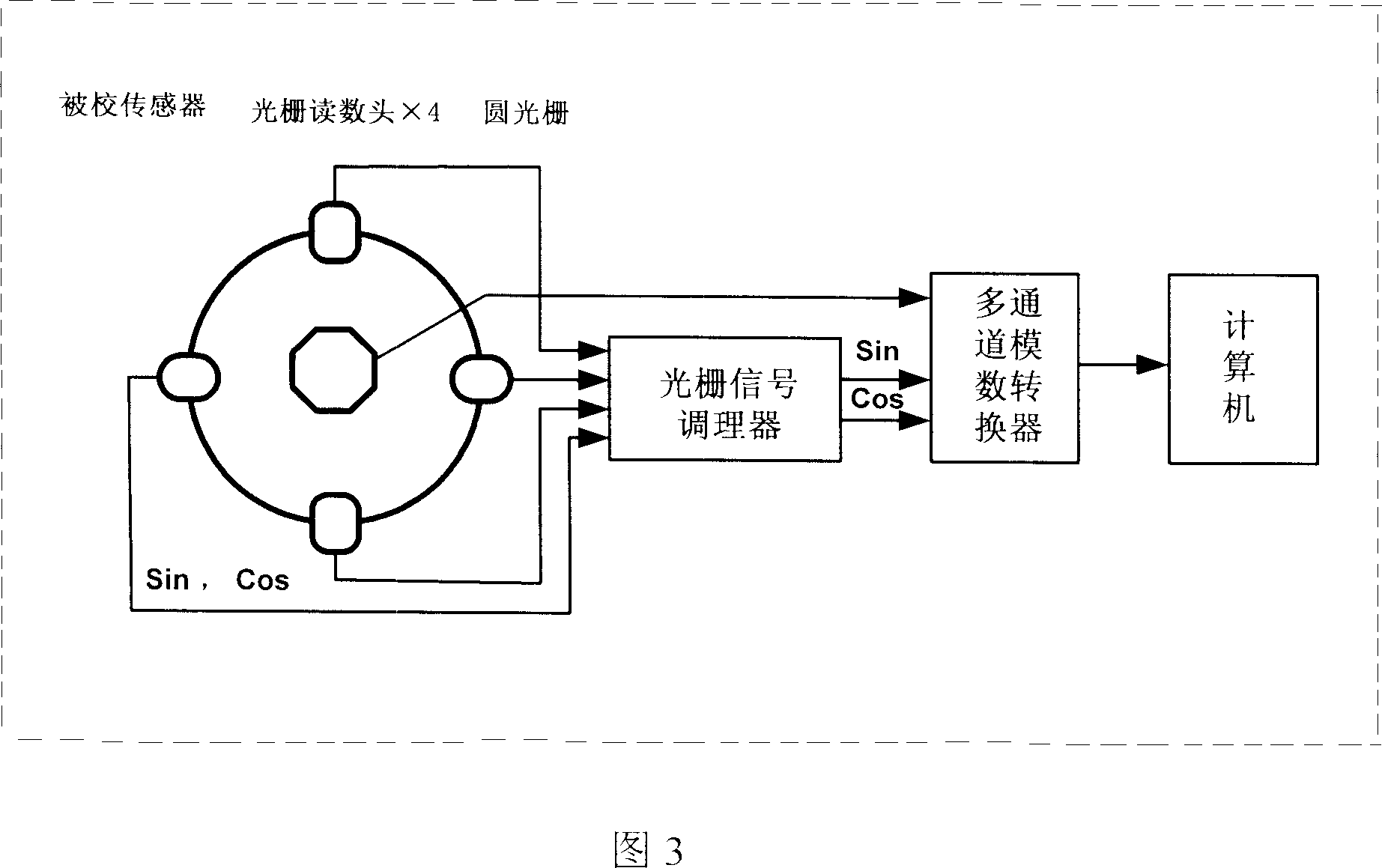

[0034] As shown in Figures 1 and 2, the generation of low-frequency angular vibration table can be traced back to the International System of Units (SI) standard angular displacement, angular velocity and angular acceleration, and the angular displacement sensor, angular velocity sensor (gyroscope, tachometer, etc.) Accelerometers are calibrated for amplitude-frequency and phase-frequency characteristics. The air-floating shaft system is adopted, and due to the homogenization effect produced by the air film, not only can high rotation accuracy be obtained, but also the friction is small and the operation is stable. The low-frequency angle vibration table mainly includes a mechanical vibration table 1, a grating 2 to be calibrated, a sensor 3, a control system 4, a reading head 5, a grating signal conditioner 6, a data acquisition system 7, and a data processing system 8; the control system controls the mechanical vibration table according to the The characteristics of the cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com