Horizontal type slew cylinder structure cracking furnace for waste steel wire blank continuous thermal cracking

A technology of thermal cracking and steel wire, which is applied in the direction of fibrous fillers, etc., can solve the problems of steel wire winding and ball blocking channels, etc., and achieve the effects of increasing turbulence, high working efficiency, and enhanced heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

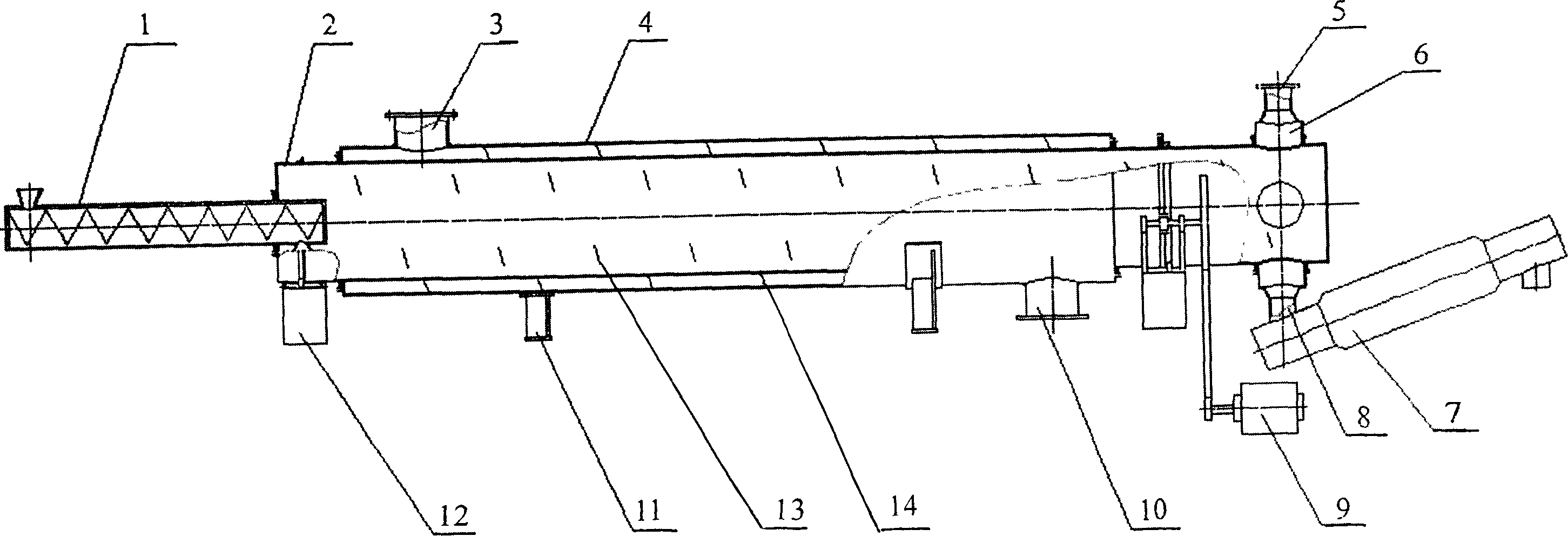

[0017] As shown in the drawings, the present invention has a stationary cylindrical outer cylinder 4, the left and right ends of the cylindrical outer cylinder 4 are respectively provided with a lower flue gas inlet 10 and an upper flue gas outlet 3, and the cylindrical outer cylinder 4 is coaxially equipped with The rotary movable inner cylinder 2 is connected with the transmission system 9 and drives the movable inner cylinder 2 to rotate. One axial end of the movable inner cylinder 2 is connected with the variable-pitch tire screw feeder 1, and the other end is connected with the static pyrolysis product The headers 6 are connected, the upper part of the pyrolysis product header 6 is provided with a gaseous cracking product outlet 5, and the lower part is provided with a solid cracking product outlet 8, which is connected with the screw discharger 7, and the cylindrical outer cylinder 4 is supported by double saddles 11, and the dynamic inner The cartridge 2 is supported by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com