Device and method for recycling gasified and burned alkali for straw pulp papermaking black liquor circulating fluidized bed

A circulating fluidized bed, papermaking black liquor technology, applied in the direction of regeneration of alkali liquor, can solve the problems of increasing operating costs, difficulty of straw pulp papermaking black liquor, etc. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

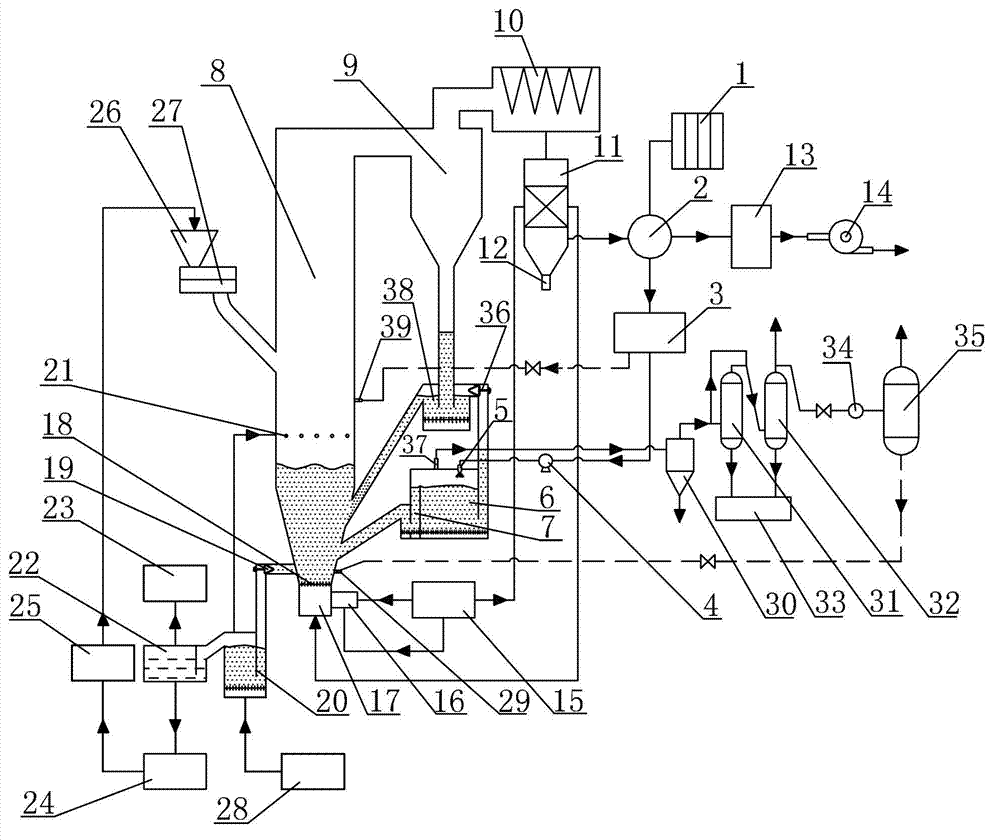

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, the straw pulp papermaking black liquor circulating fluidized bed gasification of this embodiment, combustion alkali recovery treatment device includes multi-effect evaporator 1, disk evaporator 2, concentrated black liquor tank 3, pump 4, spray gun 5 , gasification chamber 6, return valve 7, waste heat boiler 10, air preheater 11, bag filter 13, induced draft fan 14, first cone valve 19, heat exchange chamber 20, dissolution tank 22, causticizer 23 , chain plate slag removal machine 24, dryer 25, secondary fan 28, second gas-solid separator 30, tar condensation tower 31, spray dehydration tower 32, sewage treatment plant 33, water ring compressor 34, gas storage tank 35. Second cone valve 36, circulating ash distribution chamber 38 and circulating fluidized bed, said circulating fluidized bed includes furnace 8, first gas-solid separator 9, air chamber 17, air distribution plate 18, burner 16 ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 This embodiment will be described. The gasification chamber 6 in this embodiment is a bubbling bed. With such setting, the operation is stable and meets the actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 Describe this embodiment, the hearth 8 that is positioned at the upper part of secondary air inlet 21 of this embodiment is provided with dense black liquor inlet 39, and the liquid outlet of thick black liquor tank 3 communicates with thick black liquor inlet 39. Such setting can effectively provide the heat required by the furnace of the circulating fluidized bed according to actual needs, and realize energy self-sufficiency in the device without adding other auxiliary fuels. In this embodiment, the liquid outlet of the concentrated black liquor tank 3 communicates with the concentrated black liquor inlet 39 through a valve. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com