Particulate flavouring composition

一种组合物、调味料的技术,应用在,和/或高布卢,糖食产品如口香糖或牙膏的调味,挥发性调味料组分的包囊,蛋白质如明胶或酪蛋白的水溶液中,能够解决无法被感觉到、延迟咀嚼时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

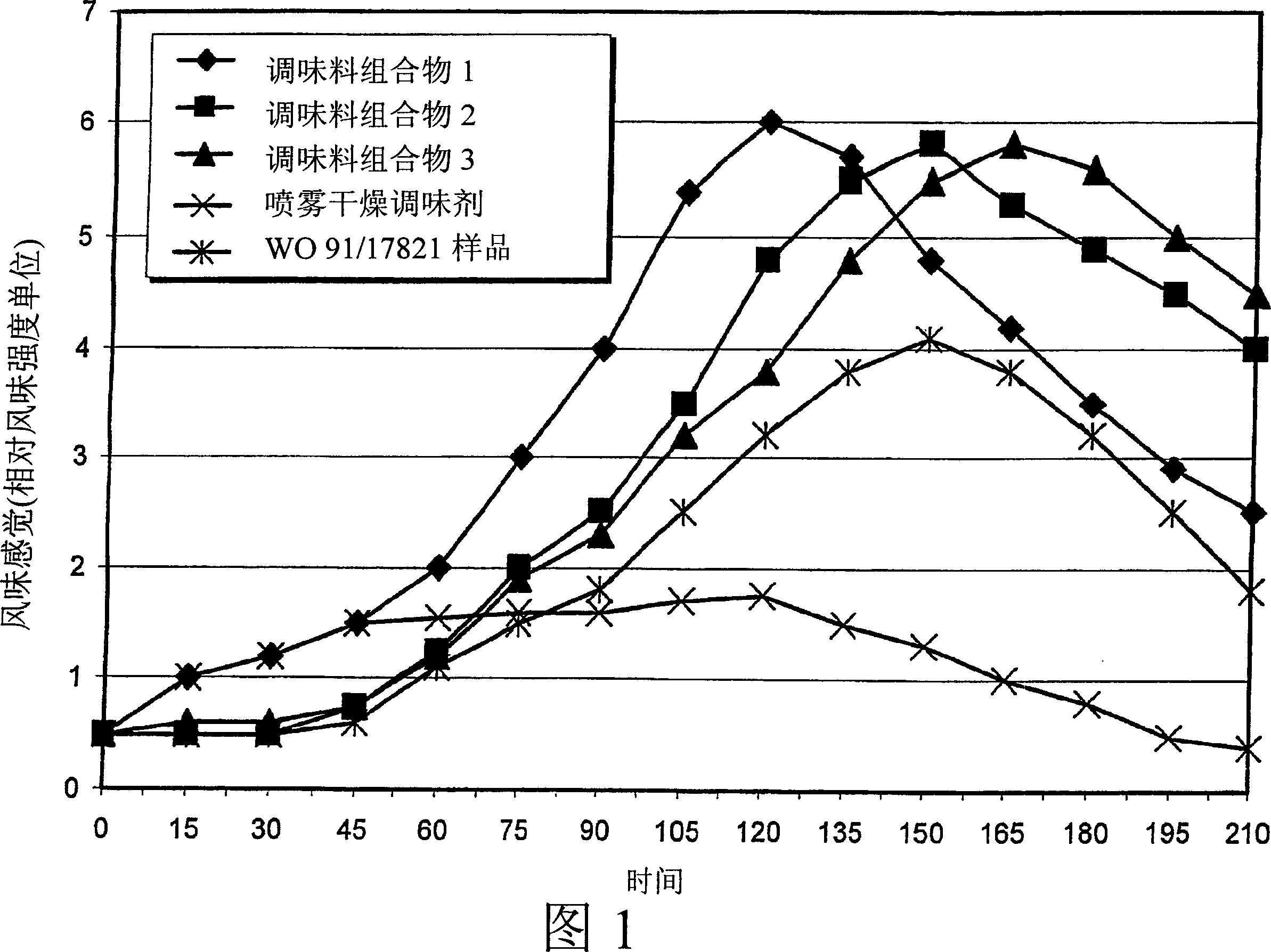

[0069] Various granular seasoning compositions were prepared according to the invention. The amounts of the different components used to prepare the emulsions are shown in Table 1.

[0070] preparation

[0071] Solutions were prepared by dispersing the first three components in water and mixing at 60°C for 30 minutes. Menthol was dissolved in fully hydrogenated palm oil (Admul PO58 5Z03910 type, manufactured by Quest International B.V.) at 60°C, which was then added to the aqueous dispersion and homogenized with an Ultra Turrax for 15 minutes at 60°C to prepare an emulsion. The emulsion was then prepared as approximately 1 cm round frozen particles in a cryogenic granulator / disruptor using liquid nitrogen. These deep-frozen microparticles were then loaded into a batch freeze dryer operating under the following conditions: temperature at -45°C, vacuum at 1 mbar, tray temperature at 20°C, and treatment time of 48 hours. The resulting material was then milled to a par...

Embodiment 2

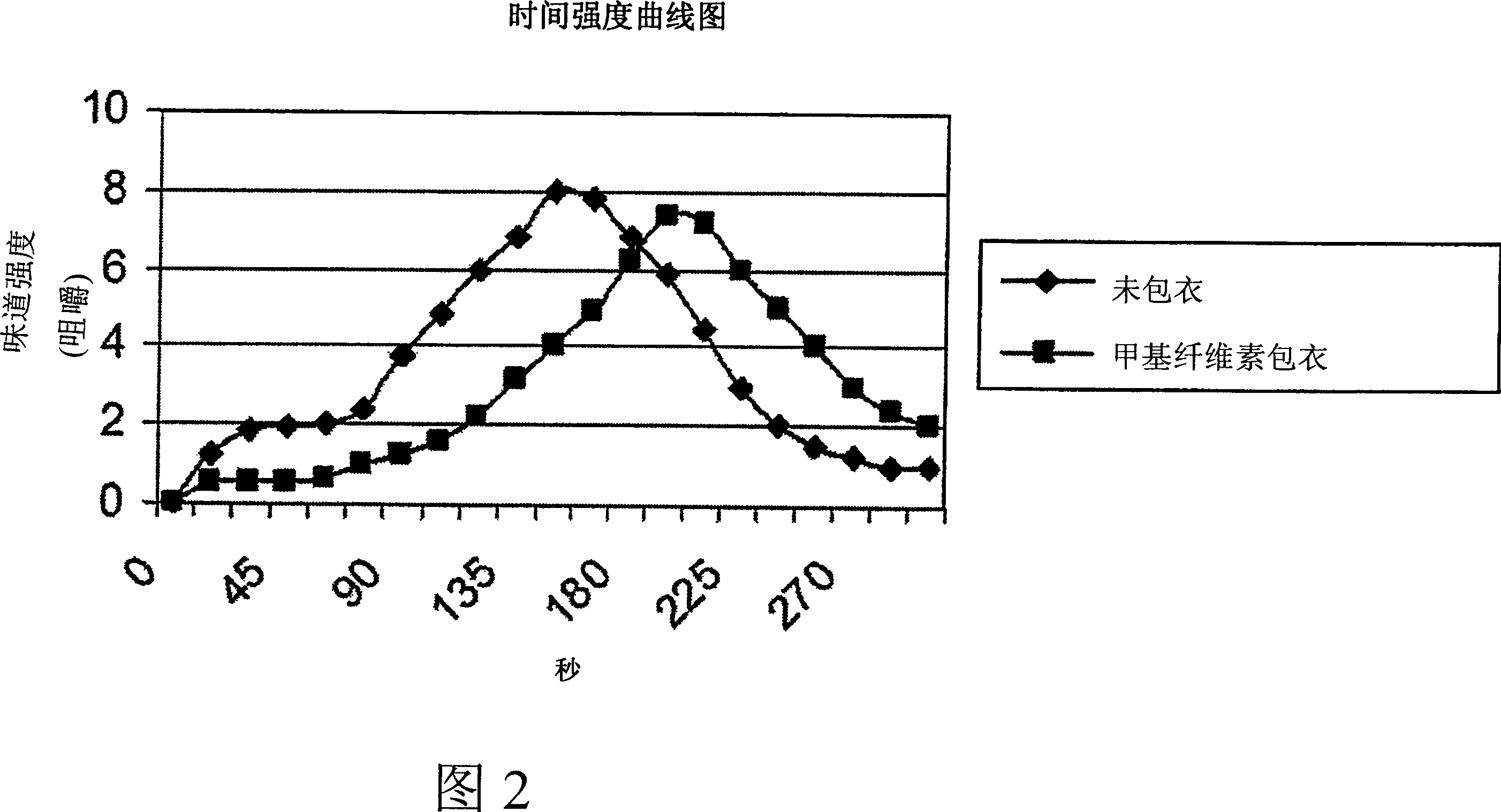

[0084]The granular seasoning composition 2 described in Table 2 of Example 1 was coated with methylcellulose by fluidized bed coating using a 4% by weight aqueous solution of methylcellulose. The coated product thus obtained contained about 3% by weight of methylcellulose.

[0085] The coated product was added to the chewing gum described in Example 1 in an amount of 1.5% by weight together with the granular flavoring composition 2 of Example 1. According to the same method as described in Example 1, the release characteristics of the chewing gum products thus obtained were evaluated by a sensory panel. The evaluation results are shown in Figure 2. These results clearly show that the application of the methylcellulose coating delays the release of the flavorant without affecting the release profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com