Operating mechanism of crane trolley

A technology of operating mechanism and crane, which is applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., can solve problems such as heavy workload, low safety, failure, etc., save manpower and material resources, reduce maintenance difficulty, reduce Create Difficulty Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

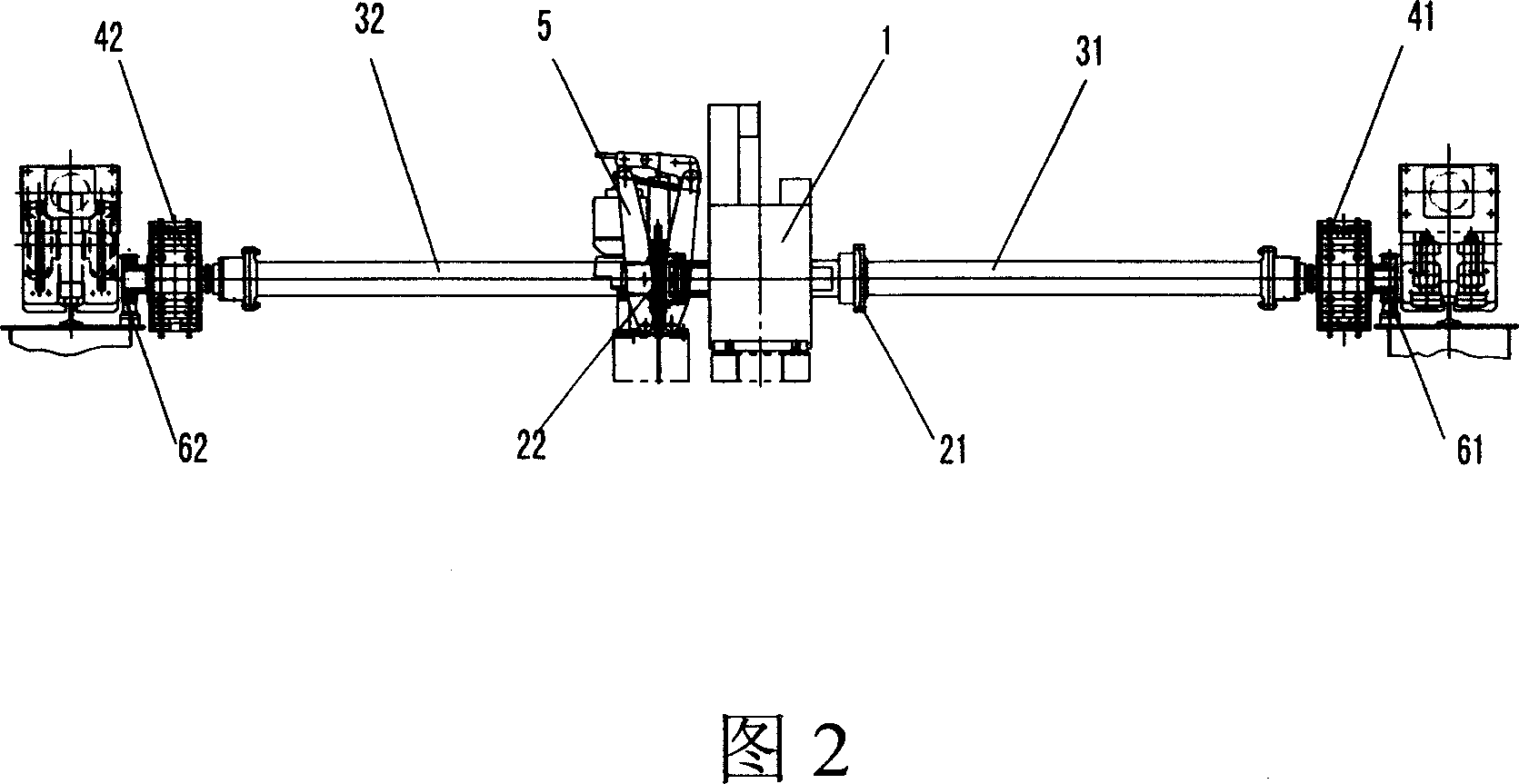

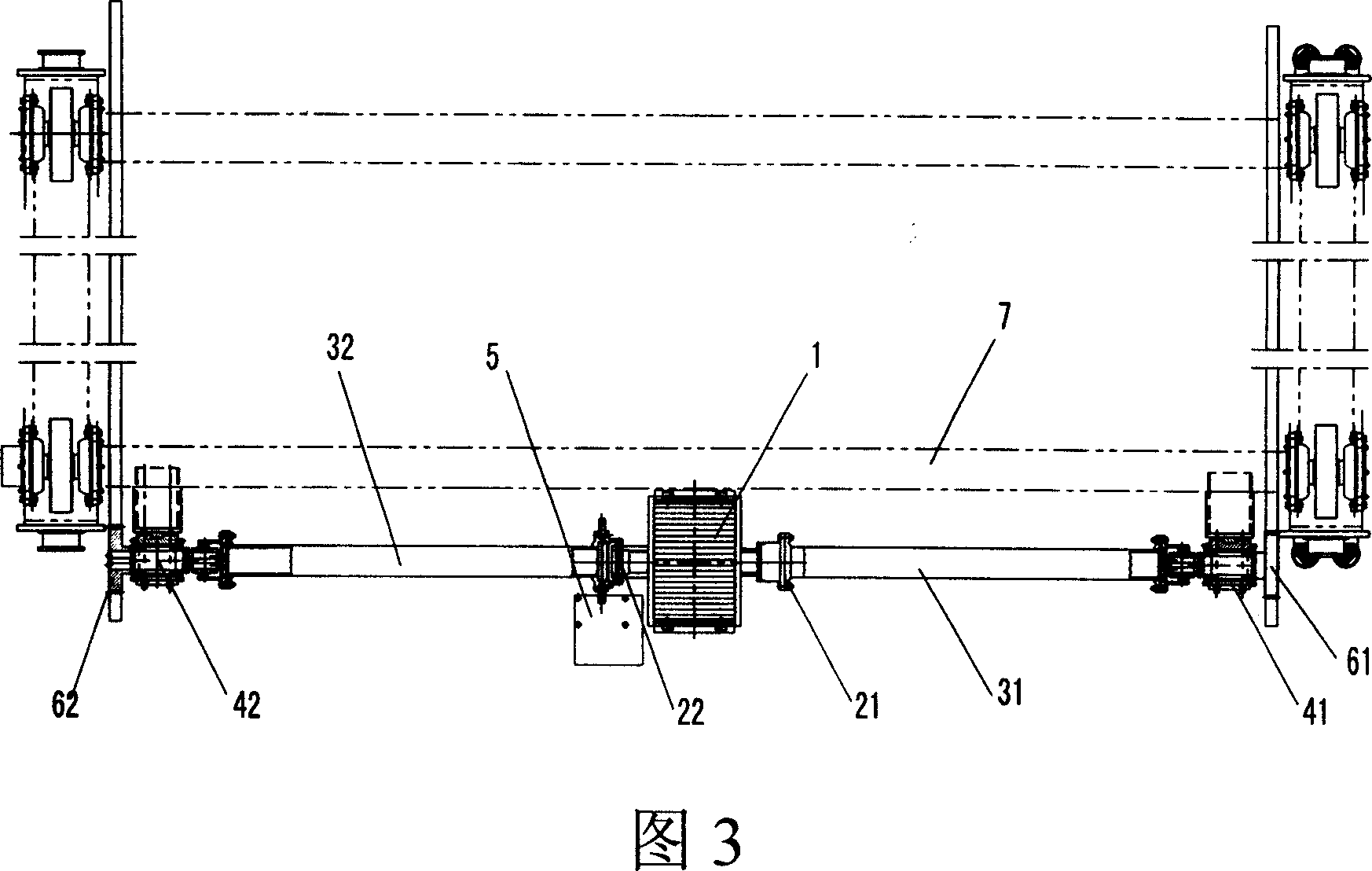

[0021] After a lot of market research and technical analysis, we found that the measure that can fundamentally solve the above shortcomings of the traditional trolley running mechanism is how to improve the driving mechanism of the trolley. mechanism. With the continuous advancement of motor technology, motor manufacturers have now developed multi-pole motors. The number of poles of the multi-pole motor has reached 60 poles, its synchronous speed has reached 100 rpm, and the output torque of the corresponding motor has been significantly improved. Generally, the speed of the trolley running mechanism of the container gantry crane is not fast, about 70m / min; the torque value transmitted by the mechanism is not large. Based on these conditions and reasons, we have done a lot of design and experiments to configure the multi-pole motor in the trolley running mechanism. The specific structure is described as follows:

[0022] Referring to Fig. 2 and Fig. 3, the trolley running m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com