Link up device of push boat/lighter

A connecting device and barge technology, which is applied to ship components, ship construction, towing/push equipment, etc., can solve problems such as mutual impact, difficult emergency disengagement, maneuverability and course stability, speed limit, etc., and achieve the goal of reducing installation requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

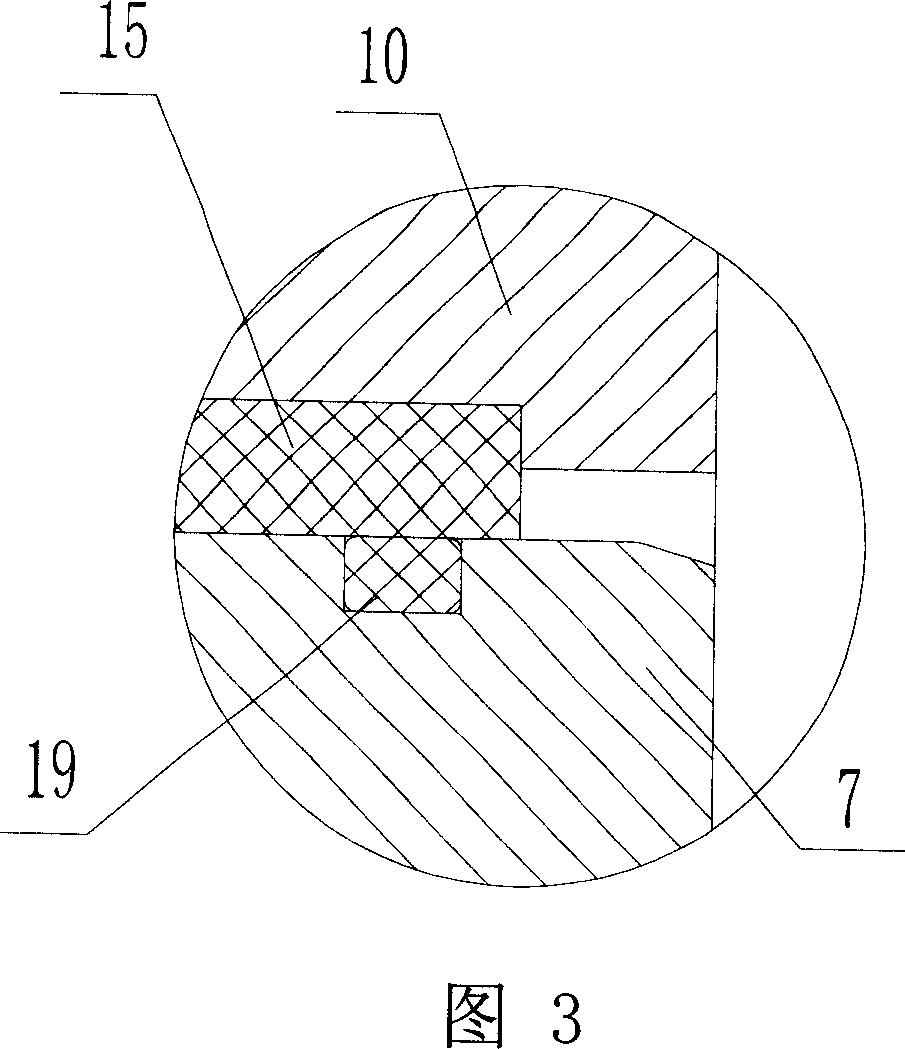

[0032] As shown in Fig. 1, Fig. 2, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 15, Fig. 16, Fig. 17 and Fig. 18, the pusher / barge coupling device includes a hydraulic cylinder 1 and a thrust bearing 5 , pin body 7, housing 9, sliding bearing sleeve 10, pin head 12, pin hole slideway plate 13, first engineering plastic alloy material MGA layer 15, common base 16, the piston rod 2 of hydraulic cylinder 1 is supported by thrust bearing 5 is hinged with the left side of the pin body 7, and the pin body 7 is a hollow cylinder, and the hydraulic cylinder 1 is fixedly connected with the left part of the common base 16 (by bolts); the housing 9 is fixedly connected with the right part of the common base 16 (Fixed connection or welding by bolts), the housing 9 is a cylindrical cavity 26, the sliding bearing sleeve 10 is located in the cylindrical cavity 26 of the housing 9 and is fixedly connected with the housing 9 by the second bolt 6, the sliding bearing The cover 10 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com