Handicraft plate made of bamboo and its making method

A production method and technology of craft boards, which are applied in the manufacture of tools, the joining of wooden veneers, the manufacture of thin wood chips, etc., can solve the problems of single surface texture of bamboo boards, easy deformation, and expand the use range of bamboo, so as to increase the appearance , the structure does not deform, the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

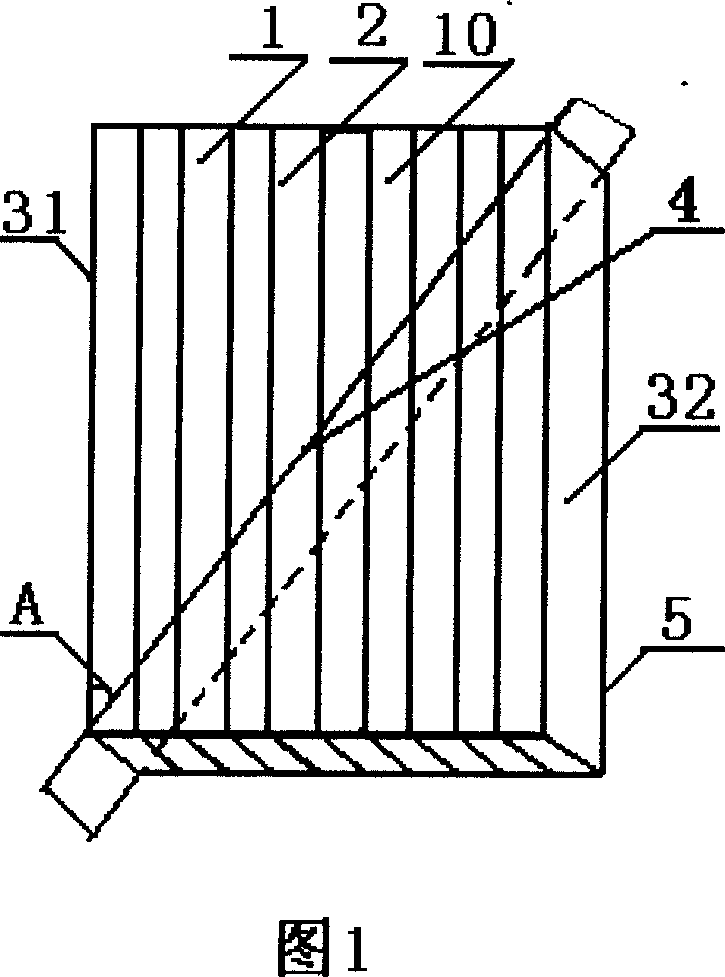

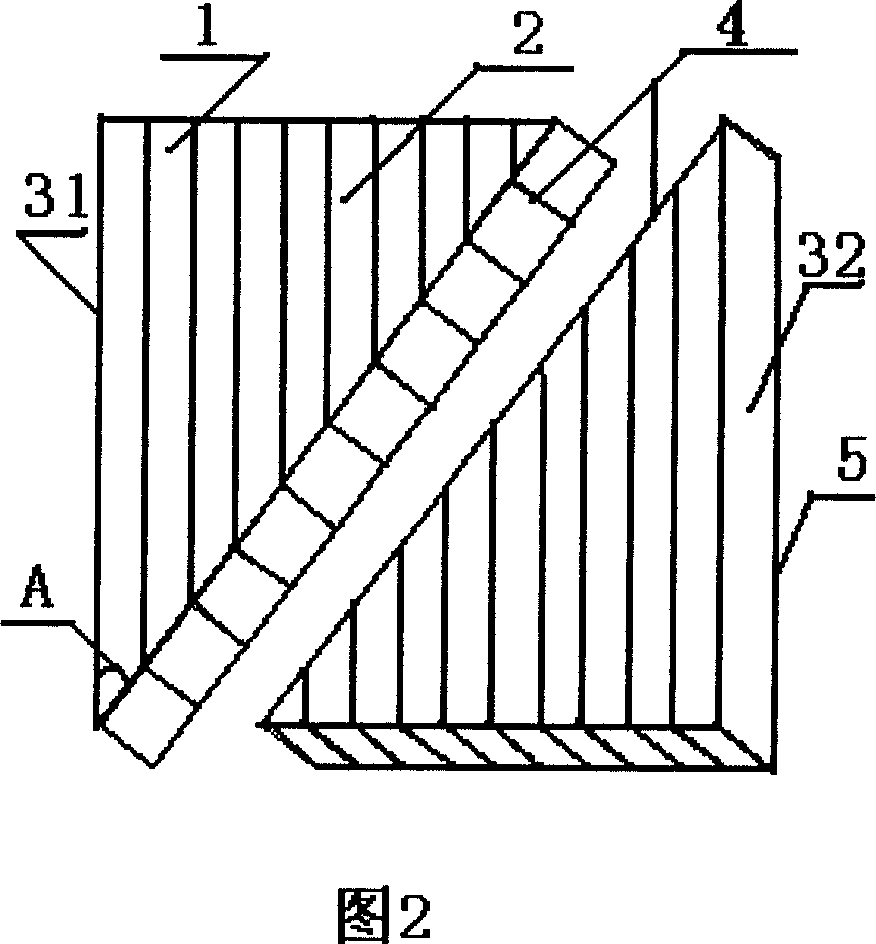

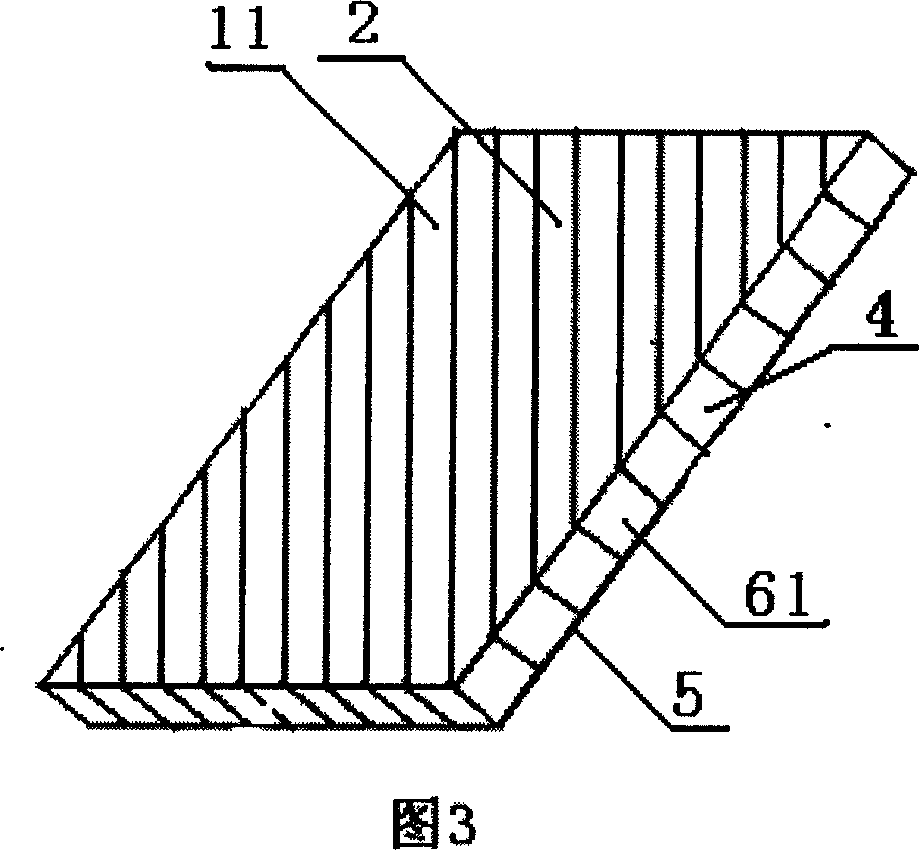

[0018] Embodiment 1: As shown in Figures 1 to 6, it is a schematic diagram of Embodiment 1 of the present invention, and the main manufacturing steps of Embodiment 1 are:

[0019] 1. Choose the bamboo base plate 10 made of bamboo slices 1, place the bottom surface 5 flat on the workbench, adopt the direction perpendicular to the surface 2 of the bamboo base plate 10, and form an angle A with the left side of the bamboo base plate 10. Sawing;

[0020] 2. After sawing and trimming, the left side 31 and the right side 32 of the bamboo blank 10 are glued to form a craft blank 11 with the sawing surface 4 as the left and right sides;

[0021] 3. Sawing the process blank 11 in a direction parallel to the sawing surface 4 of the process blank 11, forming a process strip 12 with the sawing surface 4 as the left and right sides;

[0022] 4. Glue and press the surface 2 and the surface 2 of the craft bar 12 together, and the board surface 6 formed is a bamboo craft board composed of se...

Embodiment 2

[0024] Embodiment 2: as shown in Figure 7 to 12 is the schematic diagram of embodiment 2 of the present invention, the main manufacturing steps of embodiment 2 are:

[0025] 1. Choose the bamboo base plate 10 made of bamboo slices 1, place the bottom surface 5 flat on the workbench, adopt the direction that forms an angle B with the surface 2 of the bamboo base plate 10, and forms an angle A with the left side 31 of the bamboo base plate 10 sawing;

[0026] 2. After sawing and trimming, the left side 31 and the right side 32 of the bamboo blank 10 are glued to form a craft blank 11 with the sawing surface 4 as the left and right sides;

[0027] 3. Sawing the process blank 11 in a direction parallel to the sawing surface 4 of the process blank 11, forming a process strip 12 with the sawing surface 4 as the left and right sides;

[0028] 4. The surface 2 and the surface 2 of the craft strip 12 are glued and pressed together, and the board surface 6 formed is a bamboo craft boar...

Embodiment 3

[0031] Embodiment 3: The selected size of the bamboo base board 10 described in Embodiment 3 of the present invention may be the same or different. Promptly can adopt the bamboo base board 10 of different sizes to make craft board of the present invention, then because the difference of bamboo base board 10 size, then the craft board of making, board surface 6 shapes will be rhombus or parallelogram of different sizes. crossed or parallel to each other, and the plate surface 6 can also be made into a shape that is not in a uniform plane as required. However, during production, it is necessary to satisfy that the sawing surfaces 4 are parallel to each other and can be glued to each other.

[0032] The shape of the plate surface 6 described in the present invention is several intersecting or mutually parallel squares, rectangles, rhombuses or parallelograms. As the angle changes, the shape of the plate surface 6 will change.

[0033] The value range of the angle A in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com