Rare earth sintered magnet, raw material alloy powder for rare earth sintered magnet, and process for producing rare earth sintered magnet

A technology of sintered magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of reduced strength of molded bodies, difficulties in sintered bodies, etc., and achieve the effect of improved orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

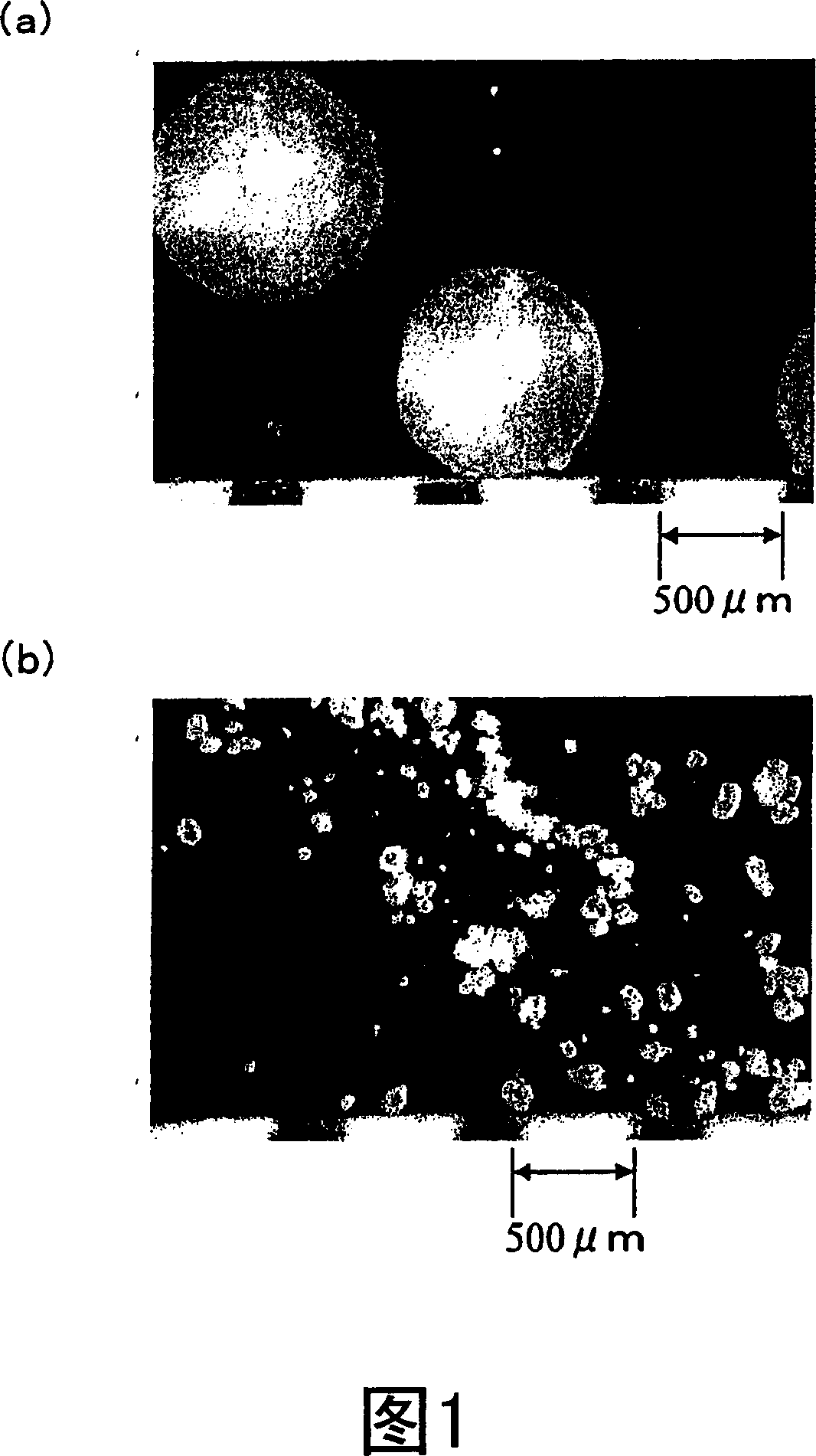

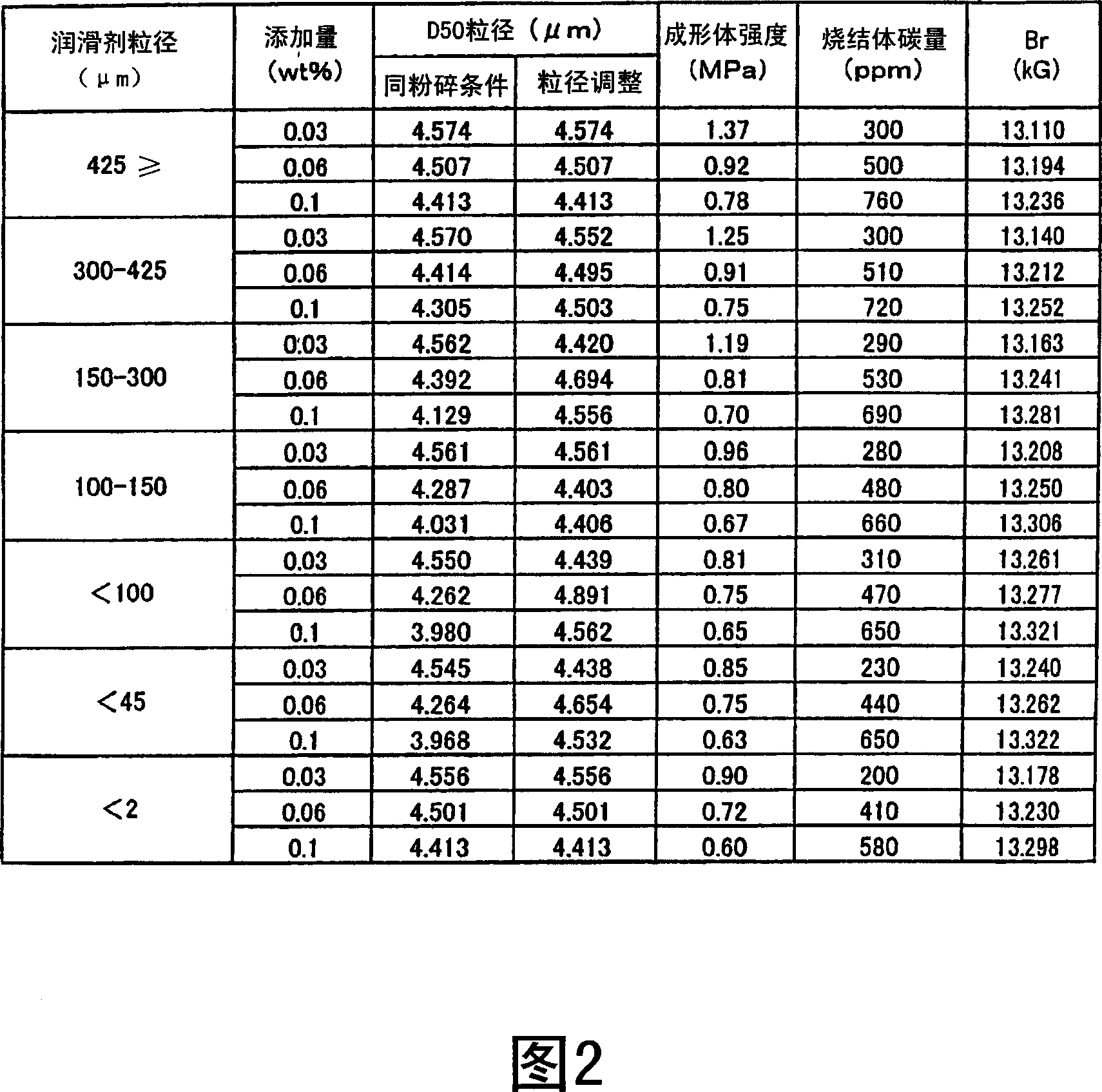

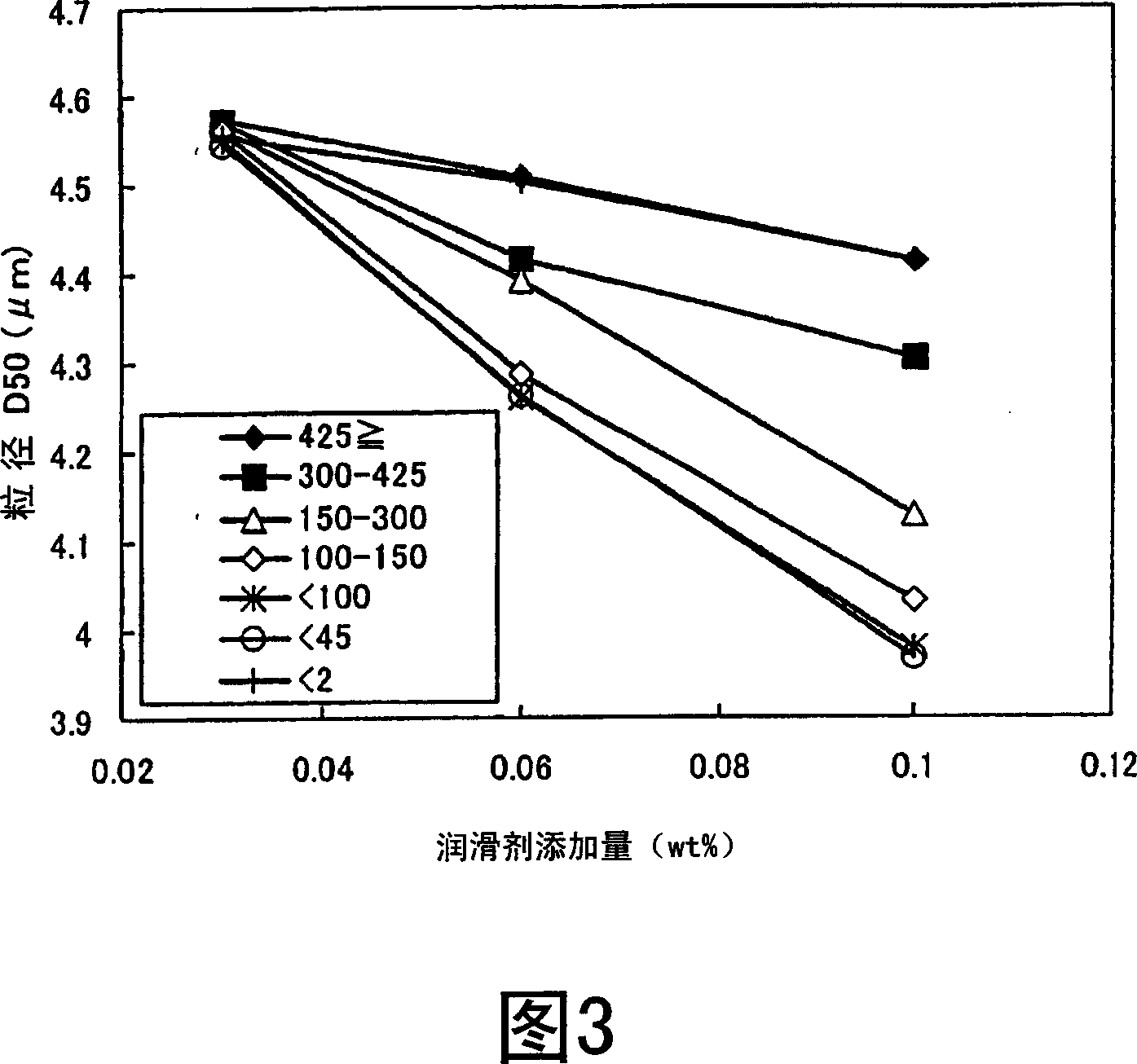

[0102] The influence of the particle size of the lubricant added in the pulverization step was investigated, and the results are shown in Example 1.

[0103] According to the composition of the raw material alloy is 24.5wt% Nd-6.0wt% Pr-1.8wt% Dy-0.5wt% Co-0.2wt% Al-0.07wt% Cu-1.0wt% B-the balance Fe to match the raw material metal or alloy , by melting and casting raw alloy sheets by the strip casting method. The obtained raw material alloy sheet was subjected to hydrogen pulverization, and then mechanically coarsely pulverized by a Brownian mill to obtain a coarsely pulverized powder.

[0104] To this coarsely pulverized powder, oleamide was added as a lubricant. Then, a finely pulverized powder was obtained using a jet mill.

[0105] Lubricants added at the time of fine pulverization were prepared in several different particle diameters. As a lubricant, commercially available oleamide (manufactured by Nippon Seika Co., Ltd., NEUTRON (trade name)) was used, and the lubric...

Embodiment 2

[0126] Then, the particle diameters of the raw material alloy (coarsely pulverized powder) and the lubricant used for fine pulverization were investigated, and the results are shown in Example 2.

[0127] The composition of the raw material alloy is 24.5wt%Pr-6.0wt%Dy-1.8wt%Co-0.5wt%Al-0.2wt%Cu-0.07wt%B-1.0wt%Fe. The raw alloy sheet is melted and cast by the strip casting method. The obtained raw material alloy sheet was subjected to hydrogen pulverization, and then mechanically coarsely pulverized by a Brownian mill to obtain a coarsely pulverized powder. This coarsely pulverized powder is formed into a flat plate with a thickness of about 100 to 300 μm and a size (length) of about 100 to 1000 μm. This was sieved and classified into 200 μm or more and less than 500 μm, and 500 μm or more but less than 800 μm.

[0128] As a lubricant, oleamide was frozen with liquid nitrogen and pulverized with a pulverizer. The obtained lubricant (lubricant particles) was classified by sie...

Embodiment 3

[0145] R-Fe-B based sintered magnets were produced in the following manner.

[0146] The raw metal or alloy is compounded according to the composition of 24.5wt% Nd-6.0wt% Pr-1.8wt% Dy-0.5wt% Co-0.2wt% Al-0.07wt% Cu-1.0wt% B-balance Fe. The raw alloy sheet is melted and cast by the strip casting method. The obtained raw material alloy sheet was subjected to hydrogen pulverization, followed by mechanical coarse pulverization using a Brownian mill to obtain a coarse pulverization powder.

[0147] To this coarsely pulverized powder, oleamide was added as a lubricant. Then, a jet mill was used to obtain a finely pulverized powder.

[0148] Several kinds of lubricants with different particle diameters were prepared for the lubricant added at the time of fine pulverization. As a lubricant, commercially available oleamide (manufactured by Nippon Seika Co., Ltd., NEUTRON (trade name)) was used, and the lubricant was frozen with liquid nitrogen and pulverized with a pulverizer. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com