Automatic needle inserting machine

A pin insertion machine and automatic technology, applied in the field of pin insertion of stamping parts, can solve the problems of unguaranteed product quality, high labor cost, low efficiency, etc., to avoid empty insertion or malfunction, save time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be explained in detail below in conjunction with the accompanying drawings and specific embodiments.

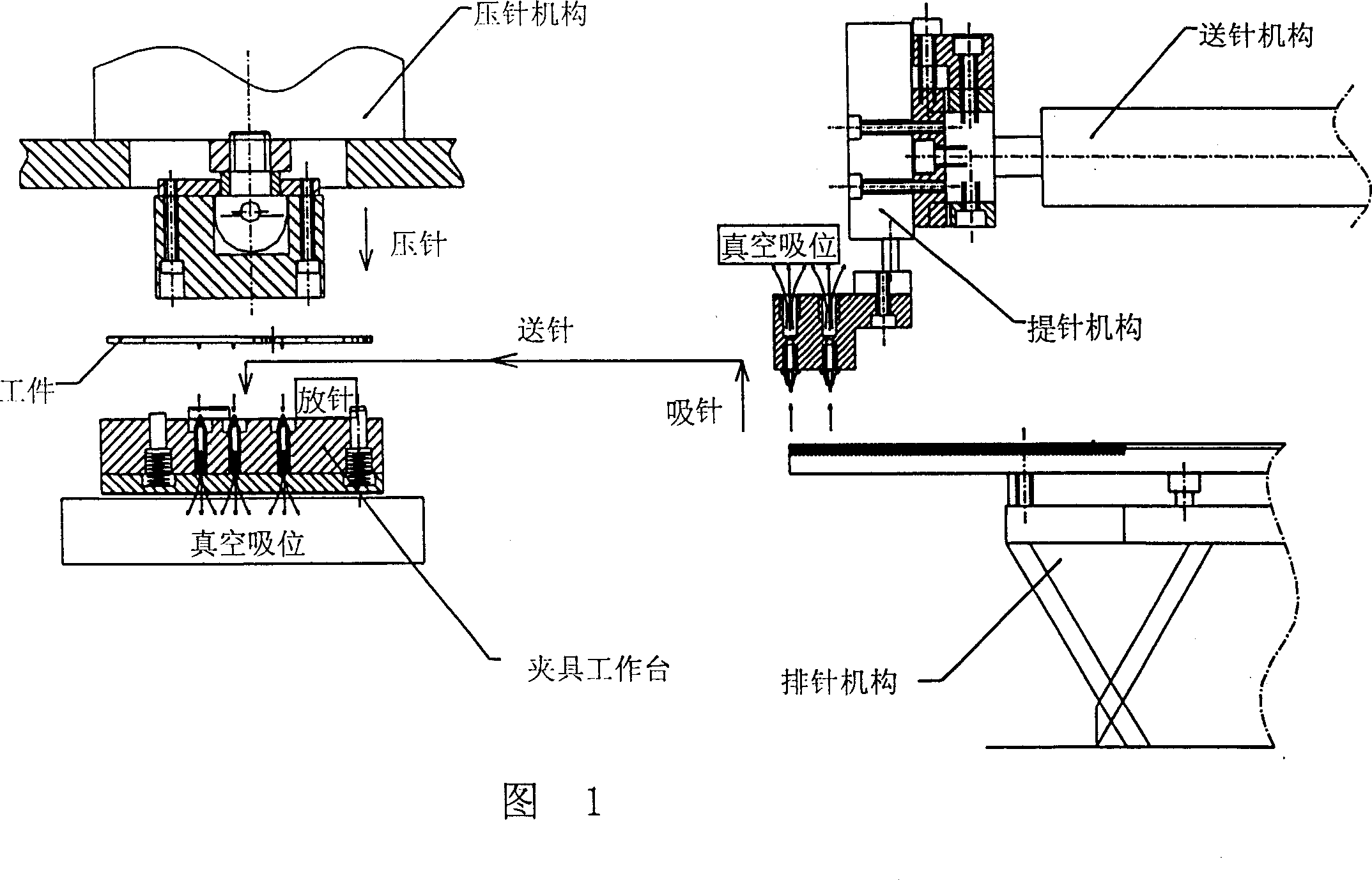

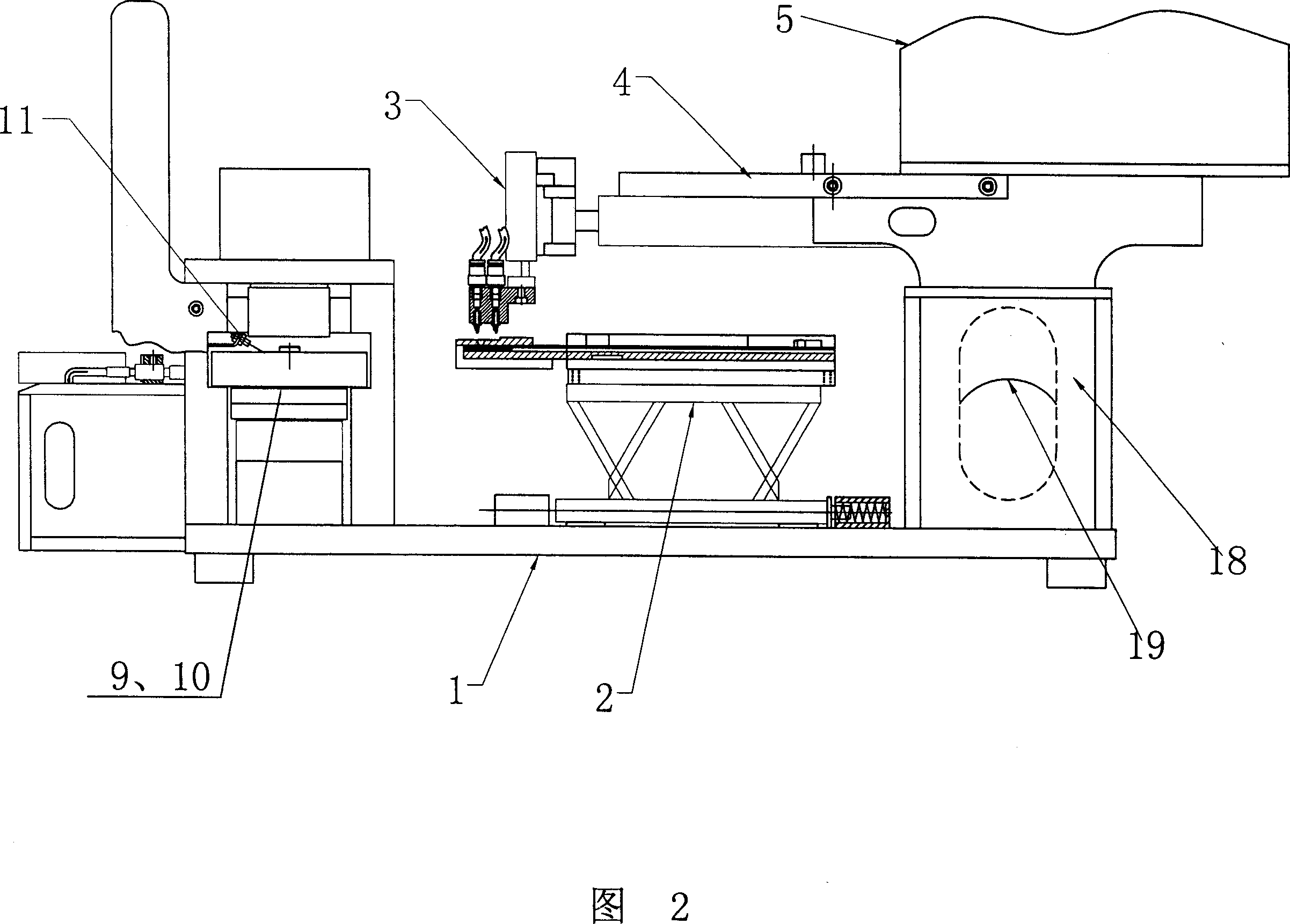

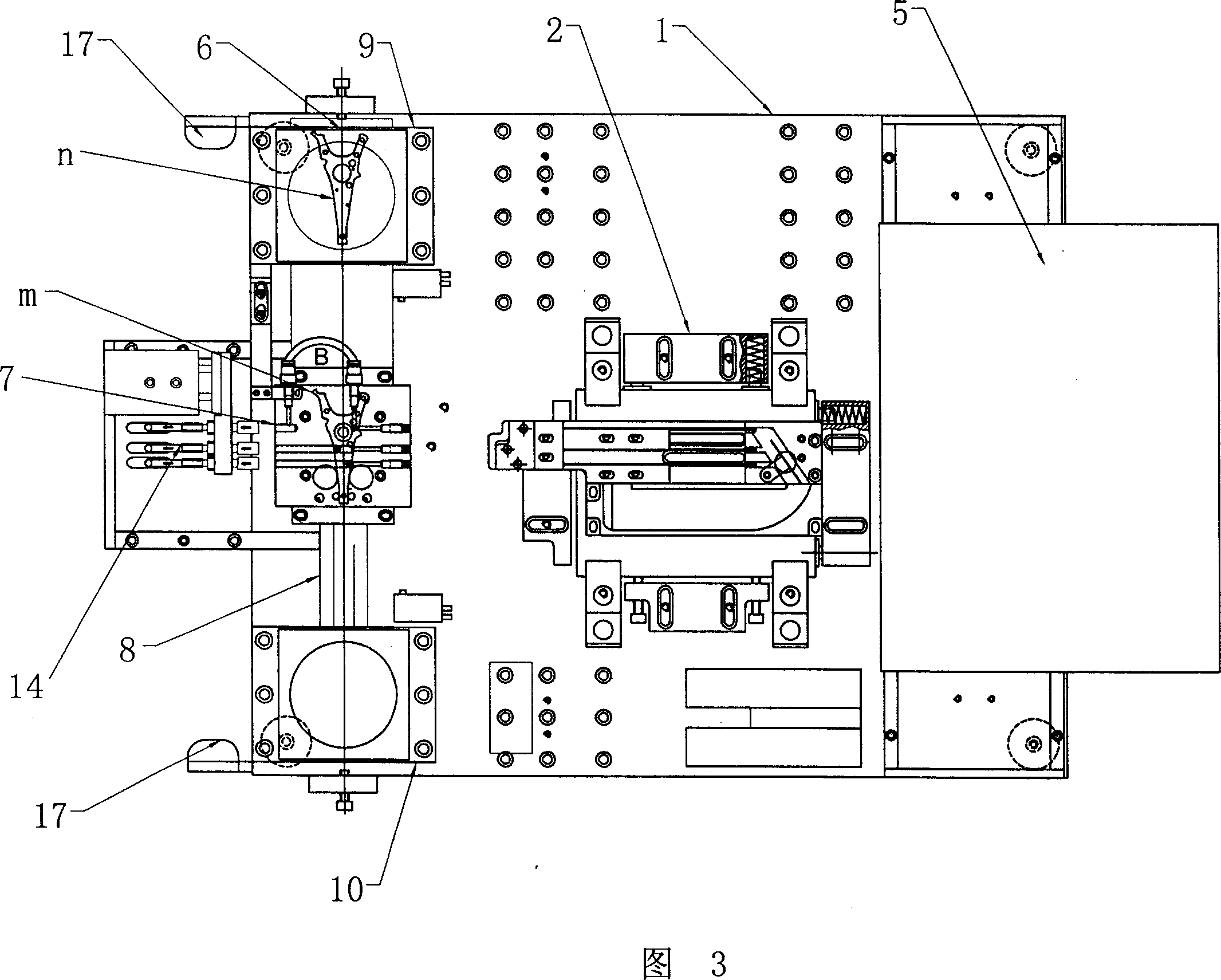

[0037] First, the working principle of the present invention will be described with respect to FIG. 1 . As shown in Figure 1, the present invention includes a base and an electric control box, the base is the carrier of the entire pin insertion machine, and other components are installed on the base, and the electric control box can accommodate the entire control system, including various start switches , control components, etc., on the bearing base, there is a fixture workbench, and the plug-in can be fixed on the fixture workbench. For example, the hard disk drive bracket that needs to be inserted or other parts that need to be processed can be placed on the workbench. It is fixed on the station, and the needle row mechanism is set behind the fixture table, including a vibrator and a suspended needle lifting cylinder. The vibrator is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com