Composite artificial board and its preparing method

A technology of wood-based panels and products, which is applied in the field of composite wood-based panels and its manufacturing, and can solve problems such as the decrease of surface bonding strength, limited wood resources, and insurmountability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

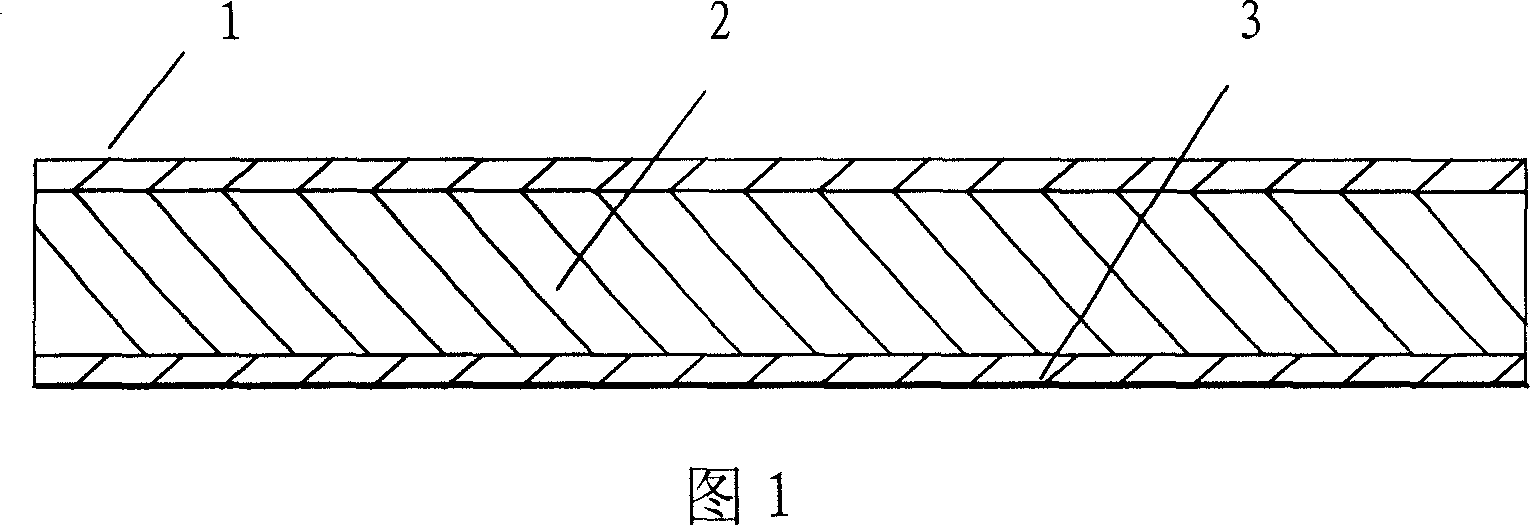

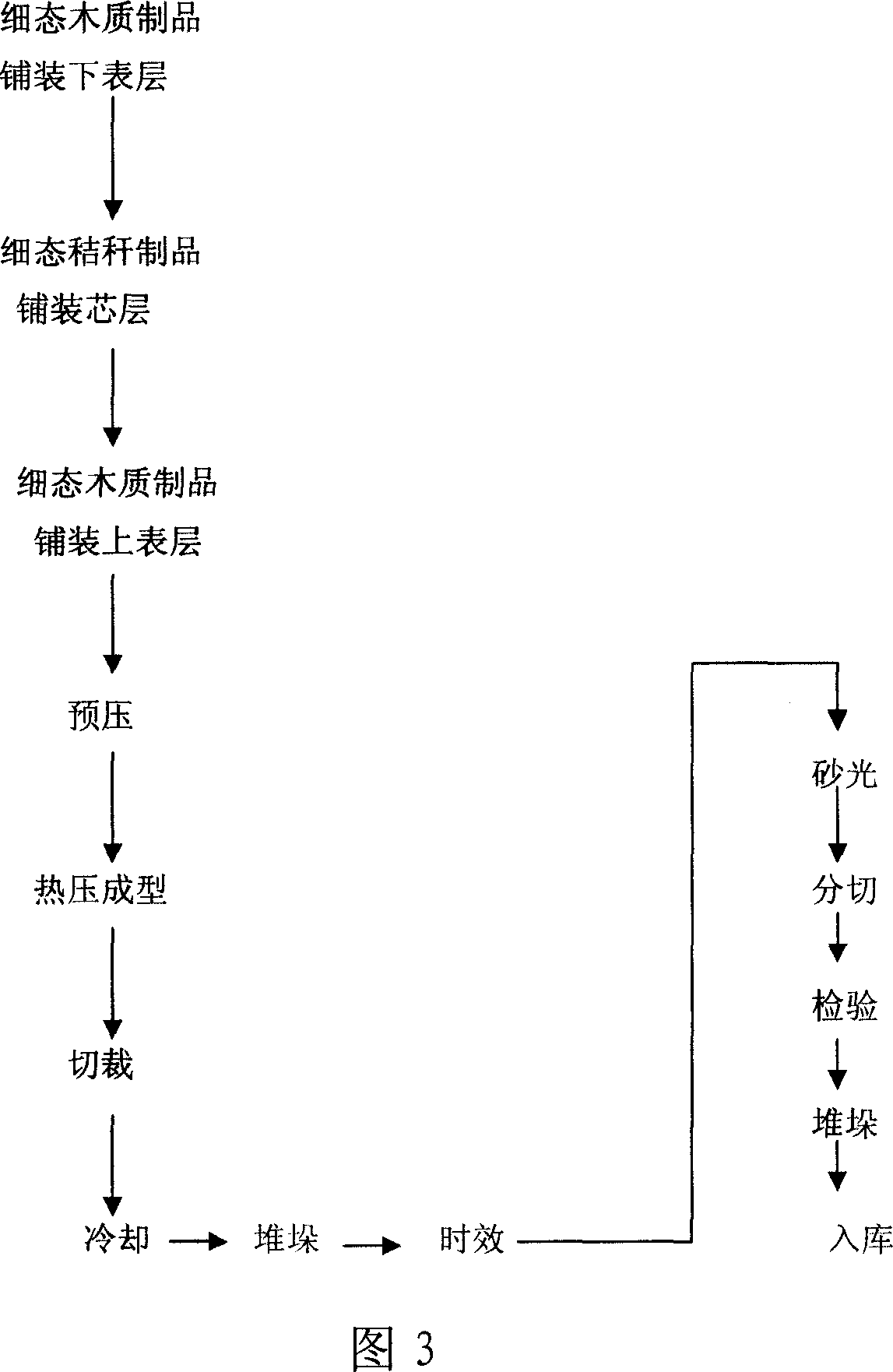

[0020] (1), wood fibers such as the three residues in the forest area, secondary small fuelwood and the like are obtained through a general process, mixed with urea-formaldehyde glue or other aldehyde glues, and paved on the press to form the lower surface;

[0021] (2) Straw is made into straw fiber by a general process, mixed with isocyanate glue, and paved on the lower surface layer to form a core layer;

[0022] (3), will be mixed with the wood fiber paving of urea-formaldehyde glue on the core layer of step 2, form surface layer 1;

[0023] (4) Then, the composite wood-based panel is obtained through pre-pressing-hot-press forming-cutting-cooling-stacking-aging treatment-sanding.

[0024] The composite wood-based panels thus prepared, after testing, the product quality conforms to GB / T1178-1999 "Medium Density Fiberboard", LY / T1611-2003 "Fiberboard for Floor Substrates", GB18580-2001 "Indoor decoration, decoration materials wood-based panels and Formaldehyde release limi...

Embodiment 2

[0027] (1), take the wood fiberboard and spread it on the press to form the lower surface layer,

[0028] (2), spread the fine state straw product that is mixed with isocyanate glue on the wood fiber board that is used as the lower surface layer to form the core layer,

[0029] (3), get the wood fiberboard and lay it on the core layer of step (2), to form the upper surface layer,

[0030] (4) Then, the composite wood-based panel is obtained through pre-pressing-hot-press forming-cutting-cooling-stacking-aging treatment-sanding.

Embodiment 3

[0032] (1), take the wood fiberboard and spread it on the press to form the lower surface layer,

[0033] (2), take the straw fiber board, spread it on the wood fiber board as the lower surface after coating aldehyde glue such as urea-formaldehyde glue on both sides, to form the core layer,

[0034] (3), get the wood fiberboard and lay it on the core layer of step (2), to form the upper surface layer,

[0035] (4) Then, the composite wood-based panel is obtained through pre-pressing-hot-press forming-cutting-cooling-stacking-aging treatment-sanding.

[0036] The fiberboard in the example can be replaced by the corresponding particleboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com