Fishy smell removing method for spirulina princeps

A spirulina and deodorization technology, applied in the field of spirulina, can solve the problems of poor deodorization effect and complex spirulina odorous substances, and achieve the effect of light fragrance and best deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The spirulina was firstly dissolved by enzymatic hydrolysis-homogenization method (the spirulina was weighed and directly dissolved in water, the mass percentage was 11%). Using lysozyme to enzymatically break the wall, the enzymatic hydrolysis conditions are as follows: the temperature is 45°C, the enzyme dosage is 100IU / ml, and the fermentation time is 3h. After the enzymatic hydrolysis, use homogeneous crushing, the homogenization pressure is 50KPa, and homogenize 3 times. Add glucose to the broken spirulina wall solution, inoculate active dry yeast, and ferment. In the yeast fermentation step, the glucose and dry yeast are respectively 0% and 0.1% of the spirulina wall solution by mass percentage.

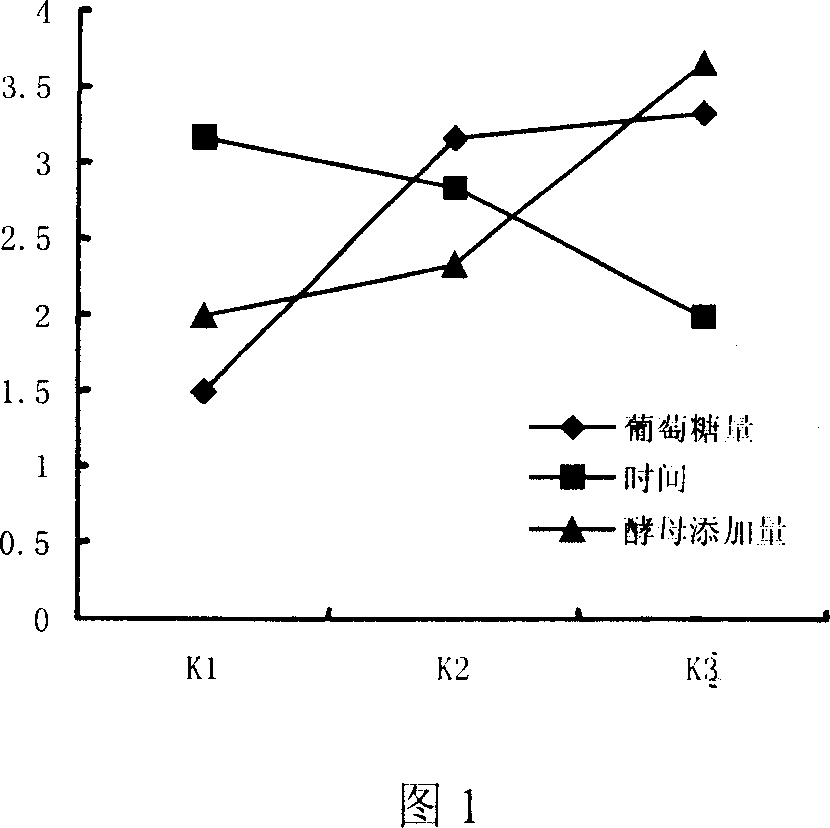

[0022] Take 50mL of the above-mentioned spiral bath solution with a mass fraction of 11% that has been broken, add different amounts of glucose, and inoculate with different percentages of active dry yeast, and ferment at 30°C for different times to check the fishy smell...

Embodiment 2

[0026] Similar to Example 1, the difference is that lysozyme is used to enzymatically break down the wall, and the enzymatic hydrolysis conditions are as follows: the temperature is 40° C., the enzyme dosage is 200 IU / ml, and the fermentation time is 4 hours. After the enzymatic hydrolysis, use homogeneous crushing, the homogenization pressure is 40KPa, and homogenize twice. Take the broken spirulina wall-breaking solution and add glucose, inoculate active dry yeast, and ferment. In the yeast fermentation step, the glucose and dry yeast are respectively 0.5% and 0.2% of the spirulina wall-breaking solution by mass percentage.

Embodiment 3

[0028] Similar to Example 1, the difference is that lysozyme is used to enzymatically break down the wall, and the enzymatic hydrolysis conditions are as follows: the temperature is 55°C, the enzyme dosage is 300IU / ml, and the fermentation time is 1h. After the enzymatic hydrolysis, use homogeneous crushing, the homogenization pressure is 30KPa, and homogenize once. Take the broken spirulina wall-breaking liquid and add glucose, inoculate active dry yeast, and ferment. In the yeast fermentation step, the glucose and dry yeast are respectively 0.3% and 0.3% of the spirulina wall-breaking liquid by mass percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com