High-cr high-ni austenitic heat-resistant cast steel and exhaust system component produced from same

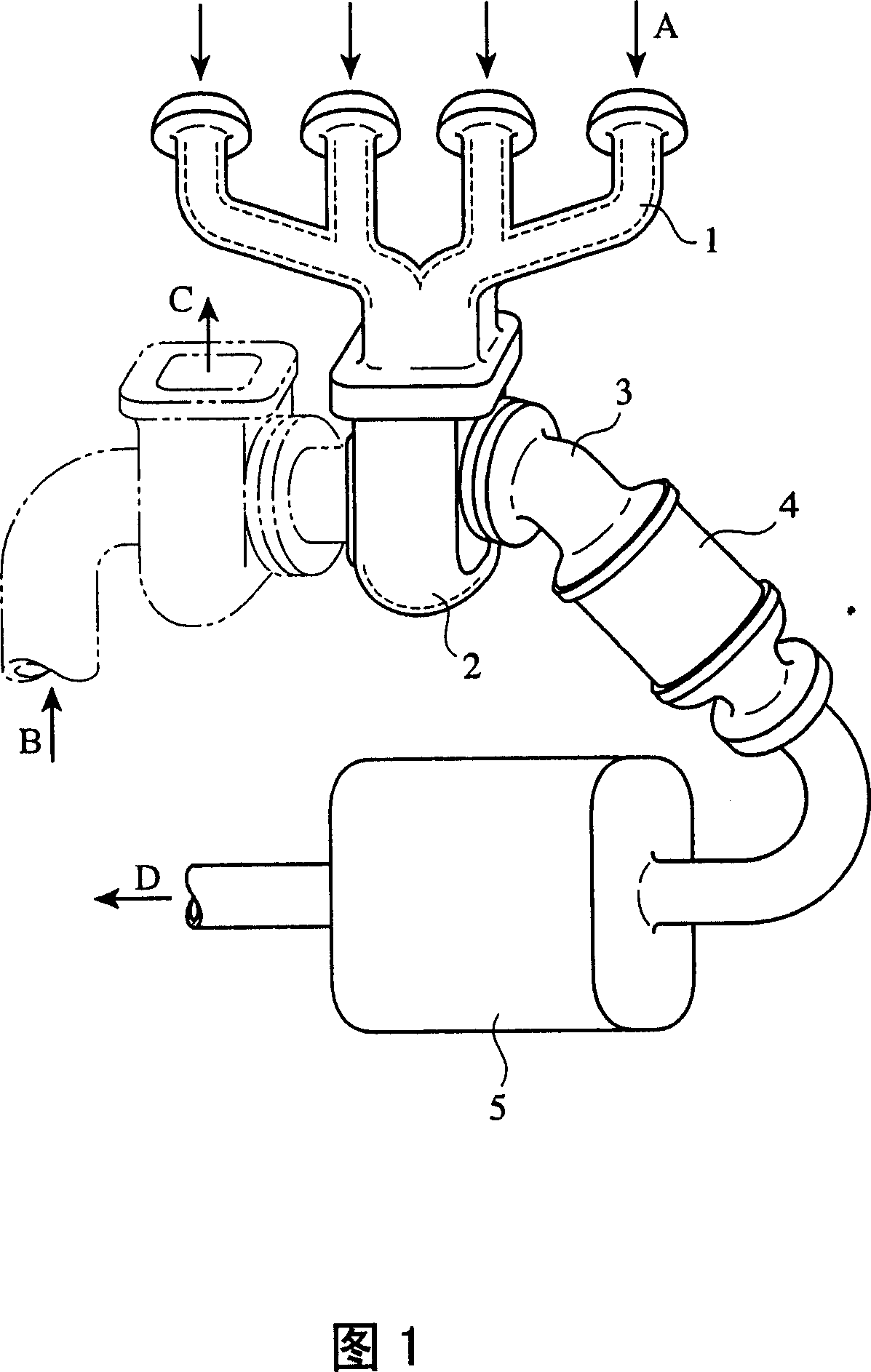

By optimizing the elemental composition of high Cr and high Ni austenitic heat-resistant cast steel, the high-temperature yield point and oxidation resistance of motor vehicle engine exhaust system parts are improved, and the problems of insufficient oxidation resistance and durability in the existing technology are solved. problem, achieving long life and efficient performance in high temperature environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~47

[0086] Examples 1 to 47, Comparative Examples 1 to 14

[0087] Table 1-1 to Table 1-4 show the chemical composition of the heat-resistant cast steel test materials of Examples 1 to 47, and Table 2-1 to Table 2-2 show the heat-resistant cast steel test materials of Comparative Examples 1 to 14 Chemical composition. Comparative Examples 1 to 8 are cast steels with excessive Al content, Comparative Example 9 is cast steels with excessive N content, Comparative Example 10 is cast steels with excessive N content, and Comparative Examples 11 and 12 are cast steels with O content. Too much cast steel, and Comparative Example 13 is a cast steel with too much O and N content. In addition, Comparative Example 14 is an example of the high Cr and high Ni austenitic heat-resistant cast steel described in JP 2000-291430 A.

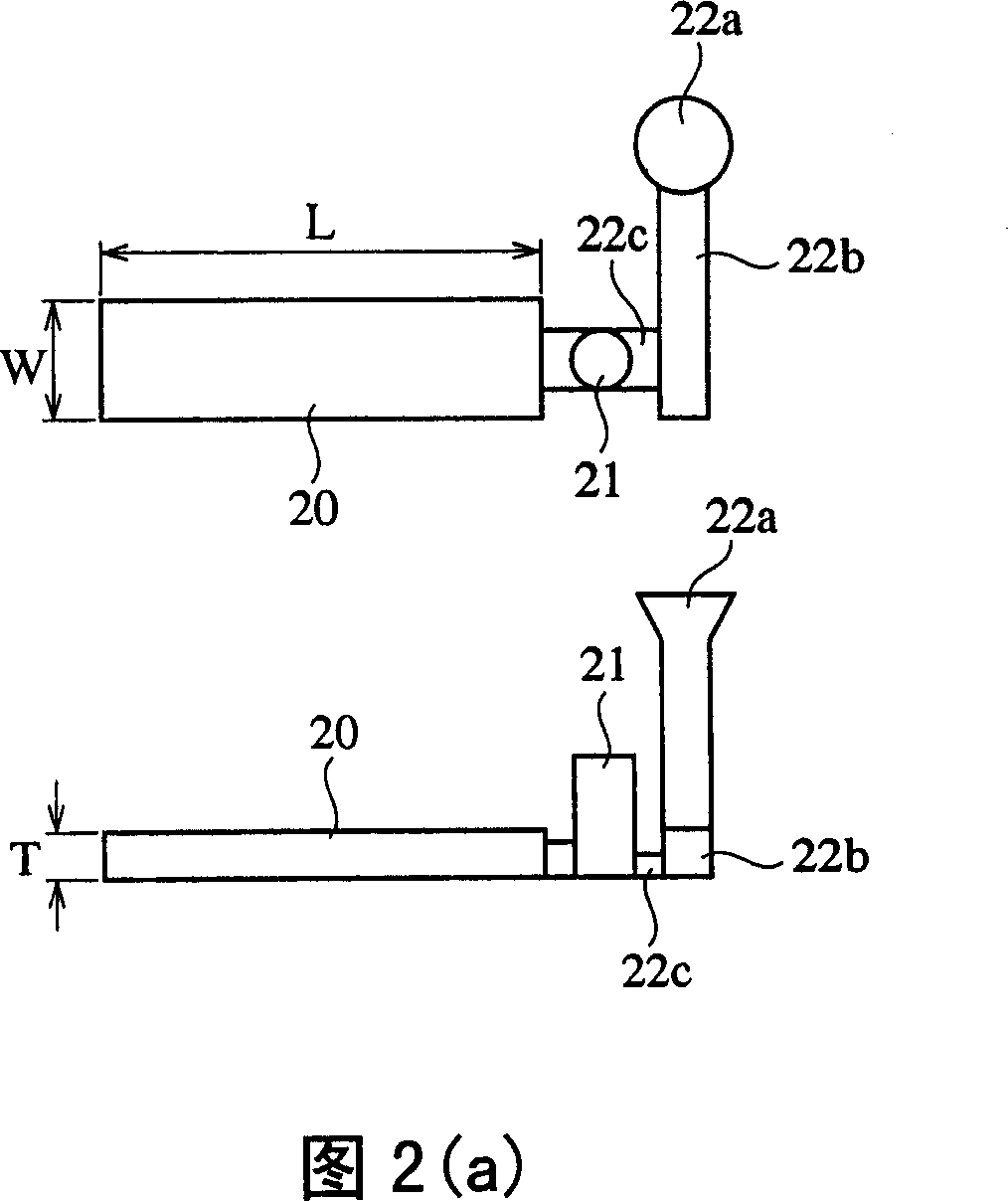

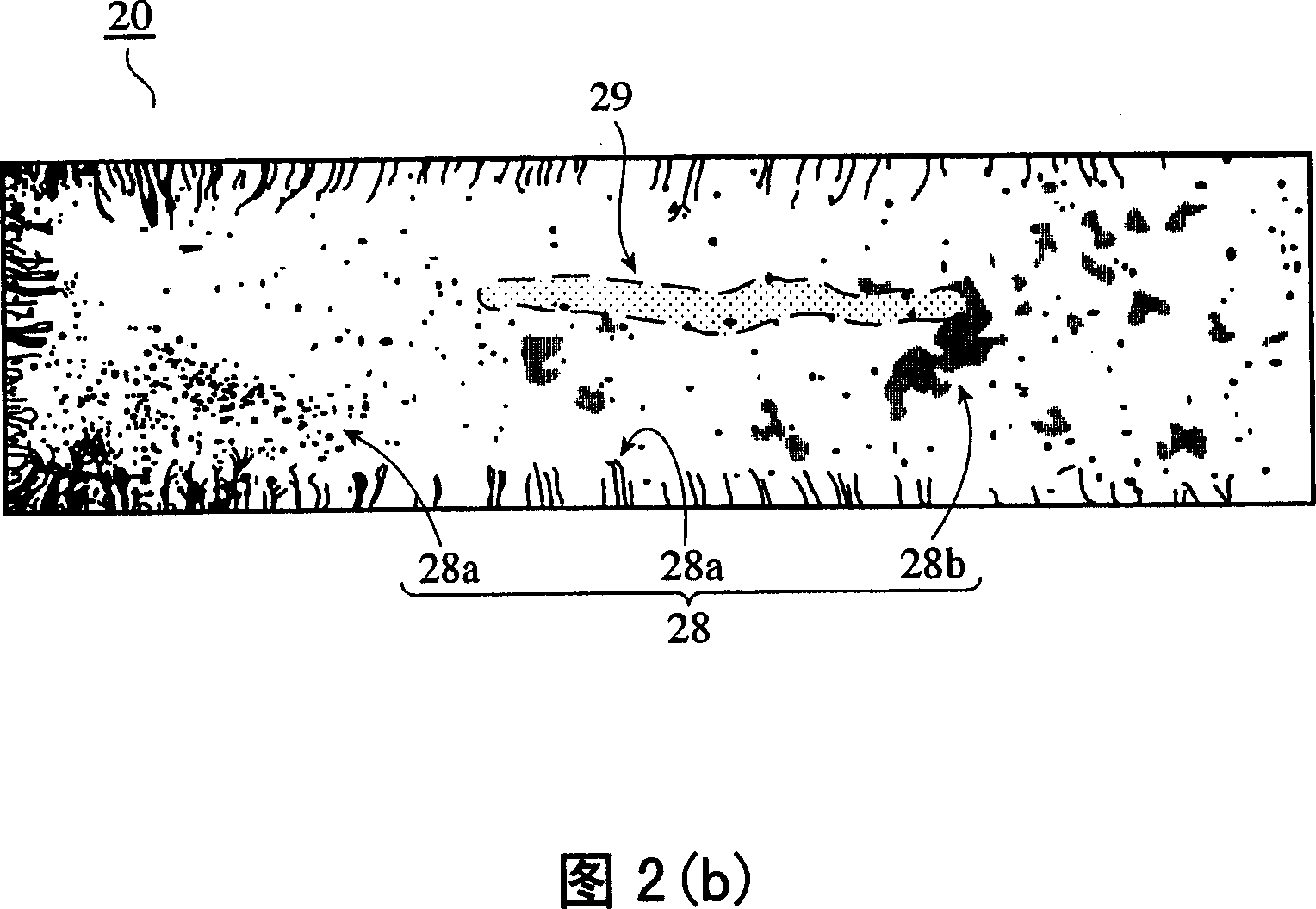

[0088] Using a 100kg high-frequency melting furnace (alkaline lining), the cast steels of Examples 1 to 47 and Comparative Examples 1 to 14 were melted in the atmosphere, t...

Embodiment 48

[0118] After the cast steel of Example 36 was melted in the atmosphere using a 100kg high-frequency melting furnace (alkaline lining), the steel was tapped into a ladle at 1550°C or higher, and immediately poured into the turbine housing 32 shown in Fig. 3 at a temperature of 1500°C or higher. Used sand molds. In order to achieve weight reduction, the wall thickness of the main part of the turbine housing 32 is made 5.0 mm or less. In addition, machining is performed on the flange of the turbine housing 32 and the like. In the obtained turbine housing 32, gas defects such as pinholes and bubbles, casting defects such as pores and stagnation were not confirmed, and there were no cutting defects due to machining, abnormal wear and damage of cutting tools, and the like.

[0119] The turbine housing 32 of this embodiment was assembled on an exhaust simulator of an in-line 4-cylinder high-performance gasoline engine (gasolineengine) equivalent to a displacement of 2000cc, and a fatigue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com