Shared voltage modification circuit and method

A common voltage and circuit correction technology, which is applied to instruments, static indicators, etc., can solve problems such as poor display quality and wrong gray-scale voltage of thin-film transistors, so as to save the number of process masks, ensure picture quality, and correct gray-scale voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

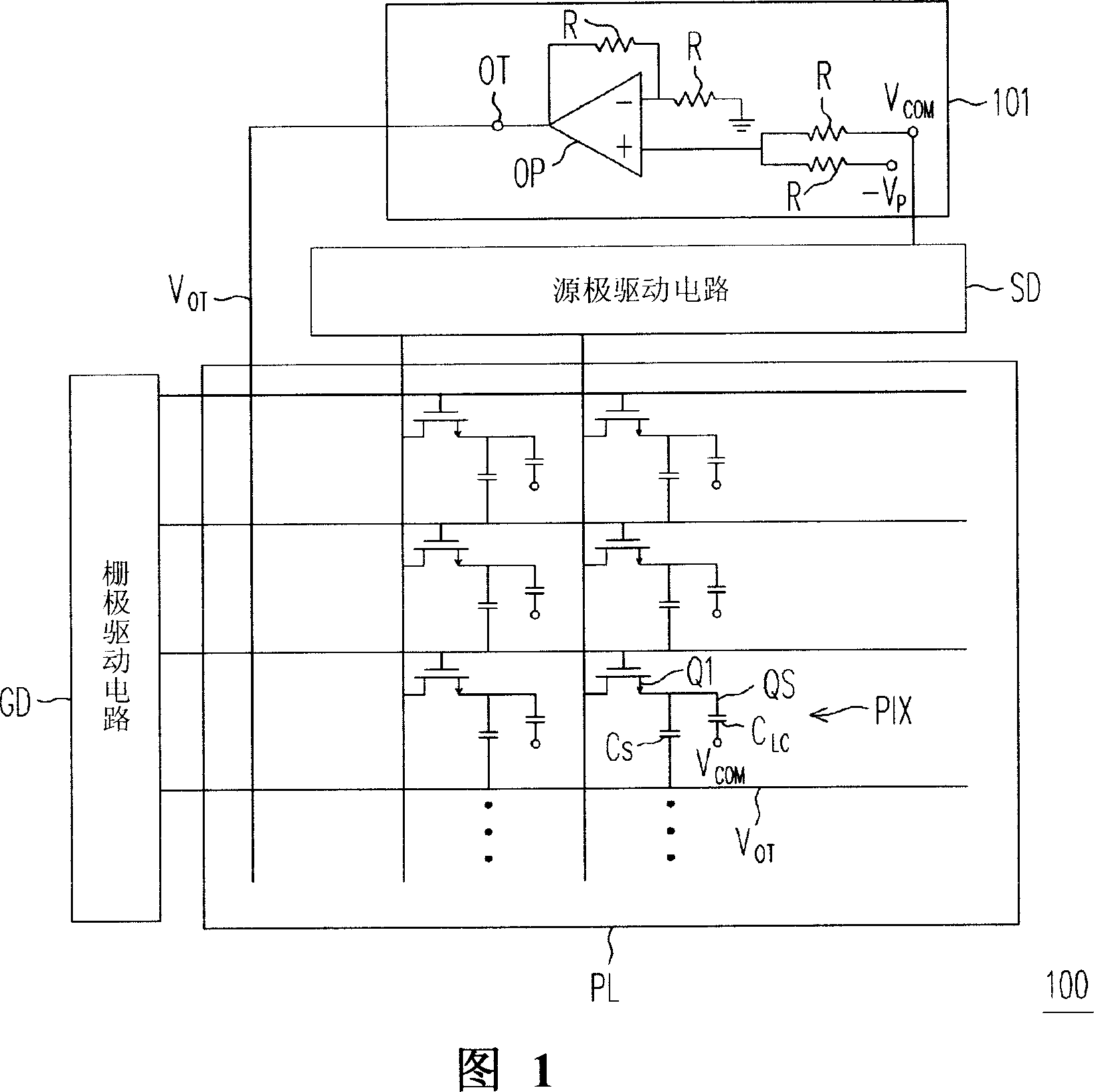

[0039] Please refer to FIG. 1 for the following description. FIG. 1 is a partial circuit diagram of a thin film liquid crystal display 100 according to a first embodiment of the present invention. The circuit in FIG. 1 includes a source driver circuit SD, a gate driver integrated circuit GD, a thin film liquid crystal display panel PL, and an arithmetic circuit 101 . The common voltage correction circuit of this embodiment includes an arithmetic circuit 101 and a source driver circuit SD.

[0040] Although the thin film liquid crystal display panel PL of FIG. 1 shows only 6 pixels, any number of pixels may actually be included. For example, the enlarged pixel PIX in FIG. 1 includes a thin film transistor Q1 , a storage capacitor Cs, and a liquid crystal capacitor CLC. The gate of the thin film transistor Q1 is electrically connected to the gate driving circuit GD, and the drain is electrically connected to the source driving circuit SD. One end of the storage capacitor Cs is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com