Arrangement of cable for fan

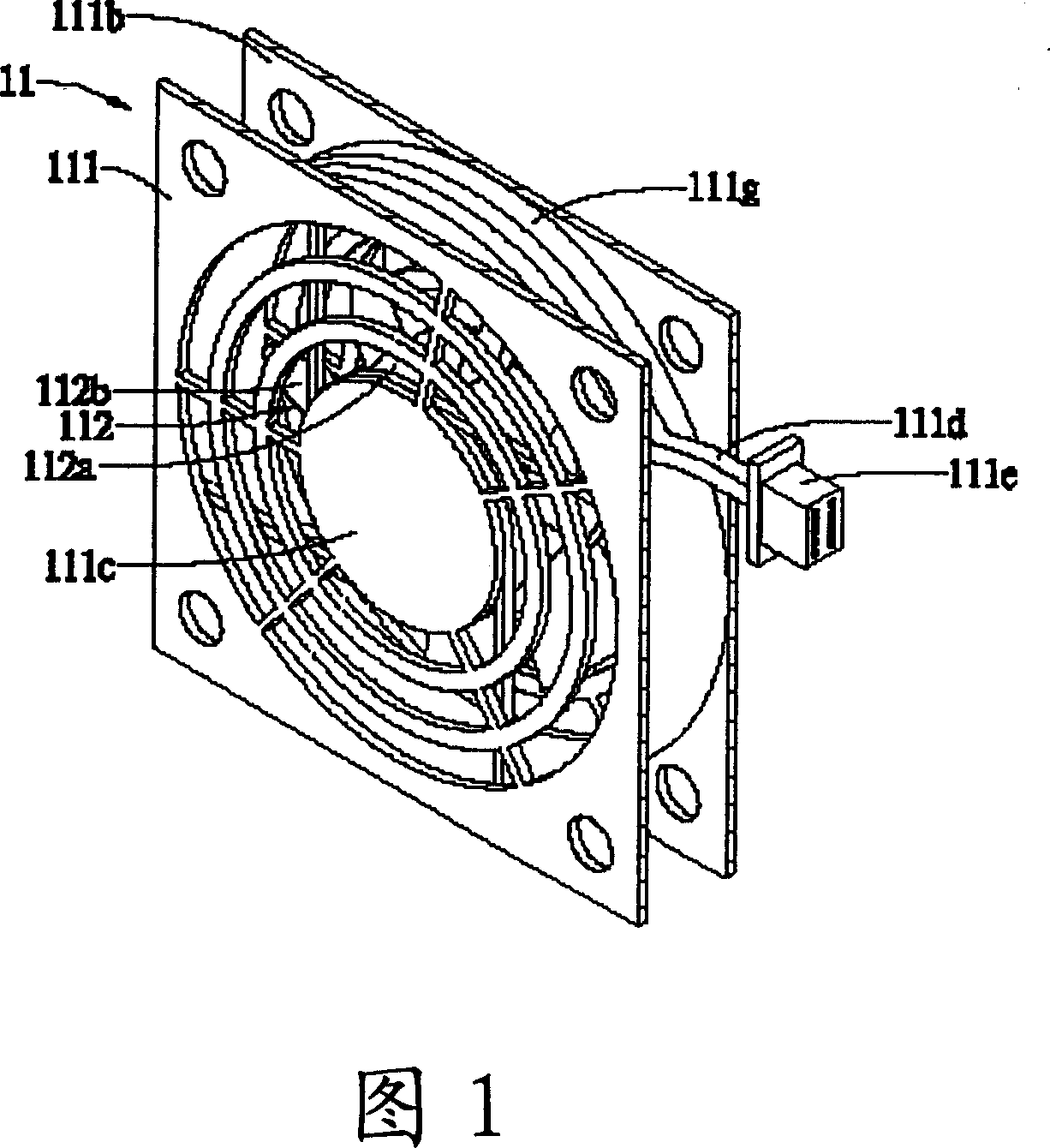

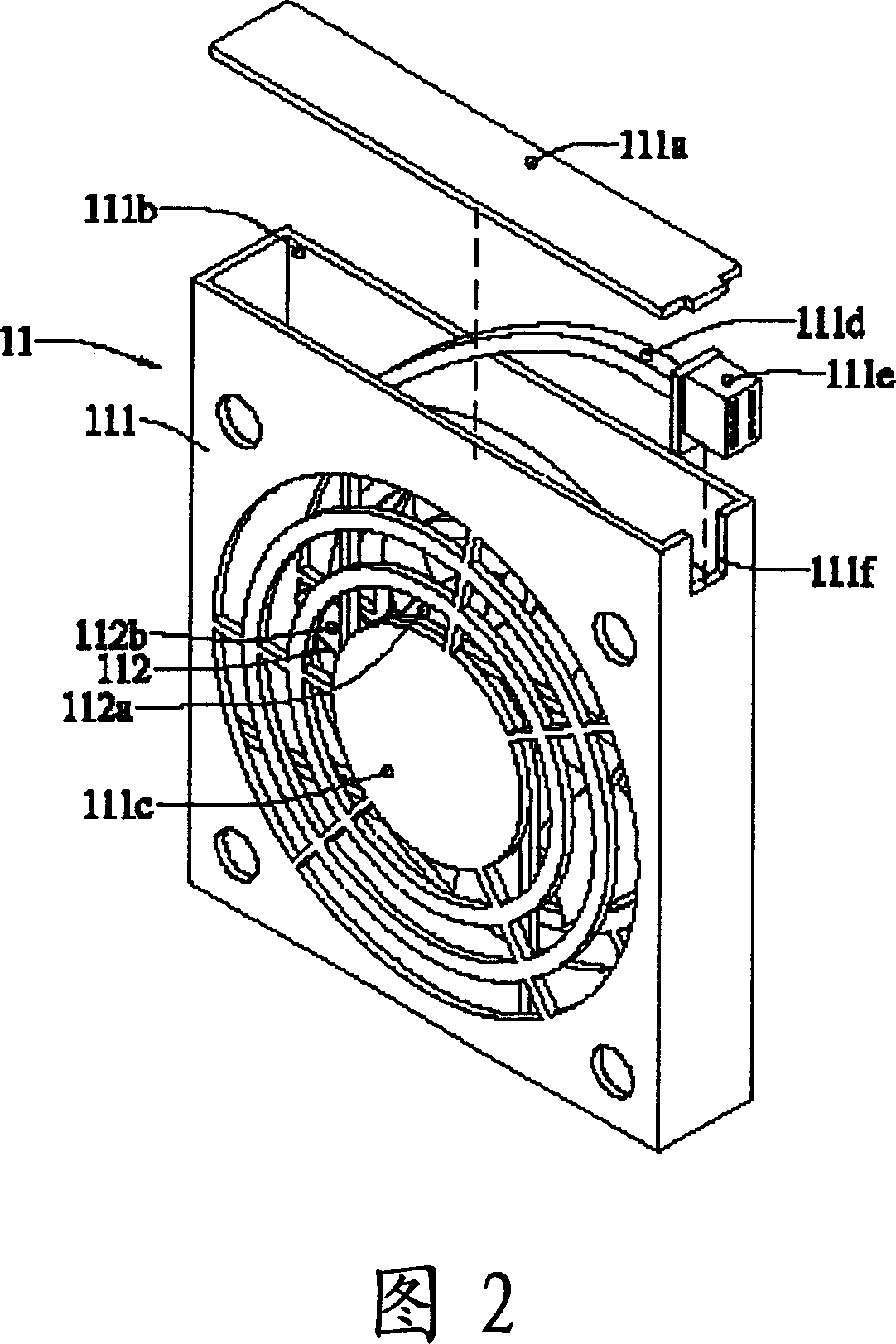

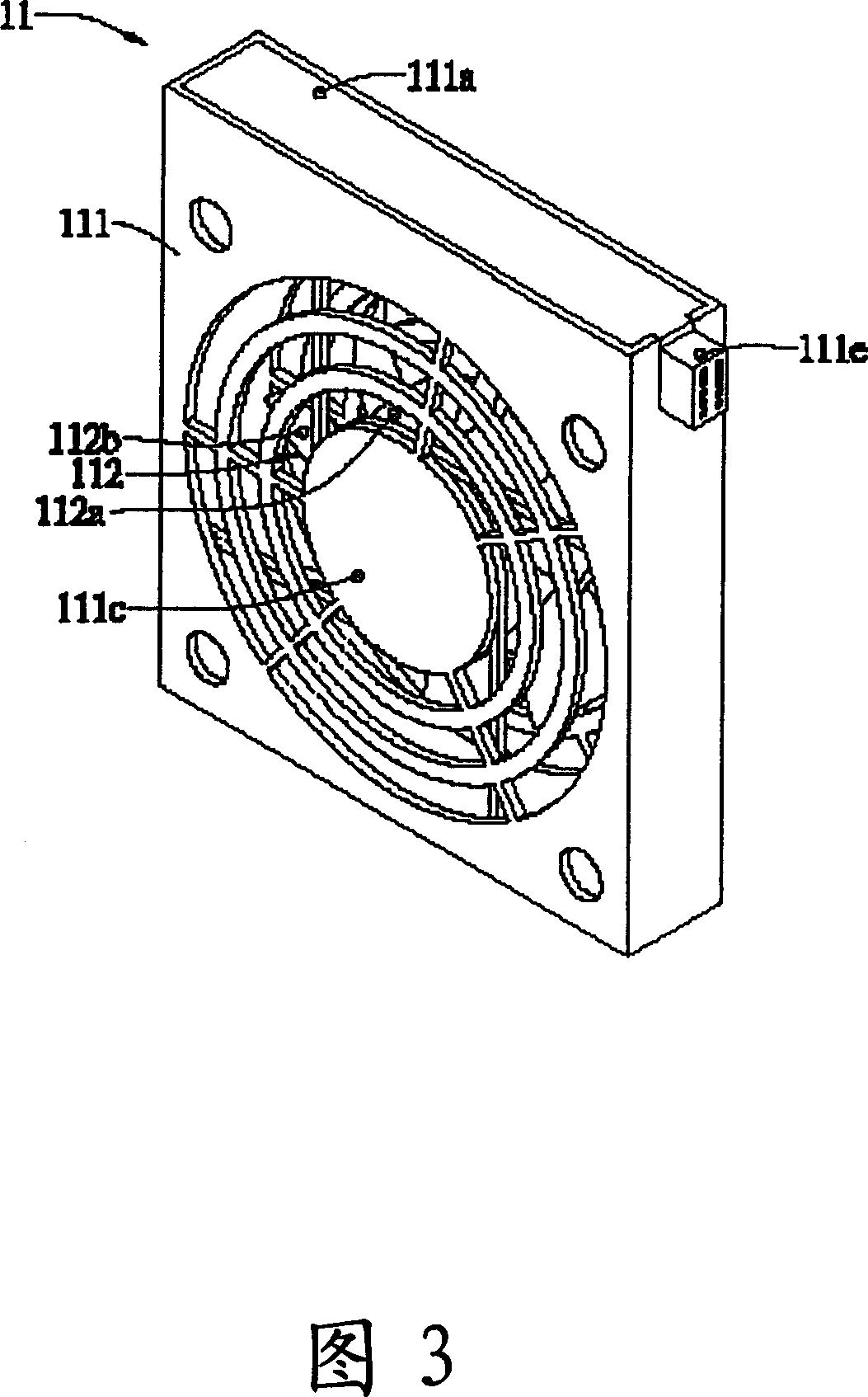

A cable and fan technology, which is applied in the field of fan cable arrangement and structure, can solve the problems of inconvenient and troublesome cable storage, the space occupied by the frame body 111, and the lack of wide application of the fan 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a fan cable arrangement structure, please refer to Figure 4, which is a preferred embodiment of the present invention, as shown in the figure, the fan 21 includes a frame body 211 and a fan blade part 212, wherein the fan blade part 212 It is composed of a fan hub 212a and fan blades 212b which are arranged around the fan hub 212a; and the frame body 211 is provided with a driving part 211c which can be pivotally connected to the fan hub 212a of the fan blade part 212, and the driving part 211c is connected to A cable 211d is provided, and a connector 211e is provided at the end of the cable 211d.

[0024] The frame body 211 is provided with a middle section 211f, and the middle section 211f is provided with a groove 211g for setting the cable 211d, and the groove 211g is provided with a stopper 211h.

[0025] Please refer to Fig. 4 and Fig. 5 again, as shown in the figure, when accommodating the cable 211d, only the cable 211d connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com