Optical-fiber sensing type railroad track scale and its data processing method

A data processing and optical fiber sensor technology, applied in signal transmission system, electrical signal transmission system, non-electrical signal transmission system, etc., can solve the problems affecting the strength of the rail, the impact of train safety, and the interference of the measurement results of resistance strain sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

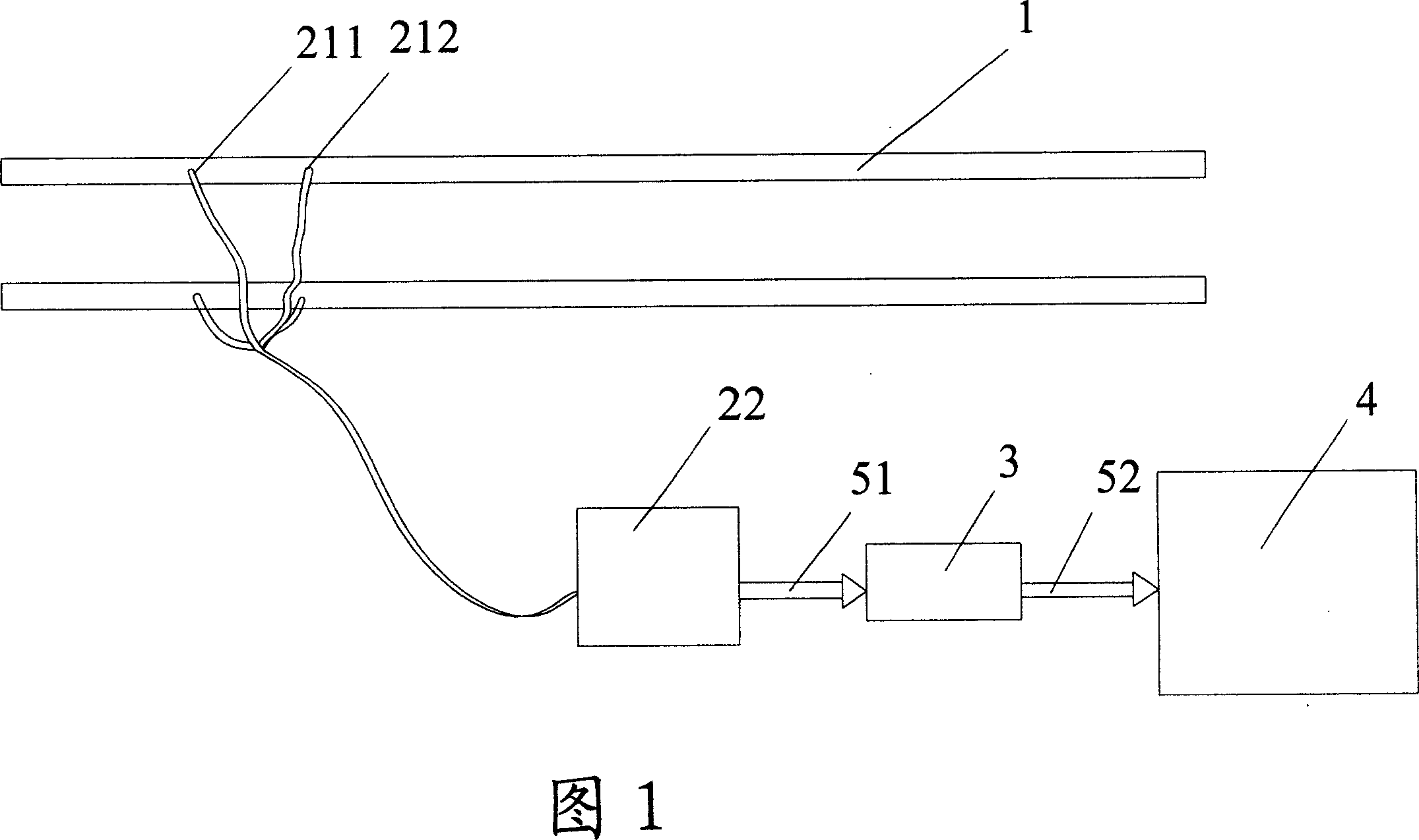

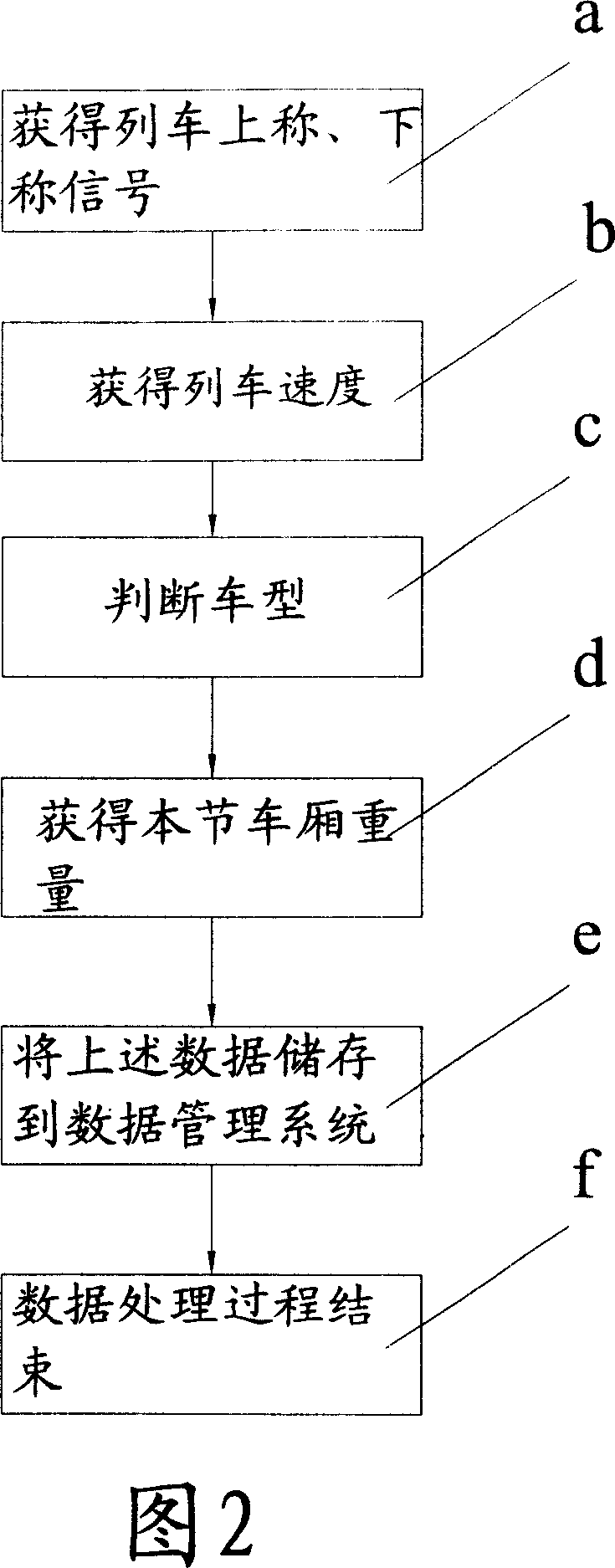

[0029] Please refer to Fig. 1, which is a structural schematic diagram of the optical fiber sensor type track scale system of the present invention. This system includes: a load-bearing beam unit, a data acquisition unit, a weighing data processing unit, a data transmission unit and a data management system, wherein, the The load-bearing beam unit described above is the rail 1 used on the railway line; the data acquisition unit includes: a first group of optical fiber sensors 211, a second group of optical fiber sensors 212 and an optical fiber modem 22, and the first group of optical fiber sensors 211. The second group of optical fiber sensors 212 is arranged on the rail 1 to obtain light wave signals, and the optical fiber modem 22 is connected to the first and second optical fiber sensors to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com