Compound enzyme preparation, and its preparing method and use

A compound enzyme preparation and enzyme preparation technology, applied in biochemical equipment and methods, applications, food preparation, etc., can solve the problems of poor feasibility, difficulty in commercialization, and long koji making cycle, so as to reduce production costs and shorten the production cycle , Enzyme dosage with moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

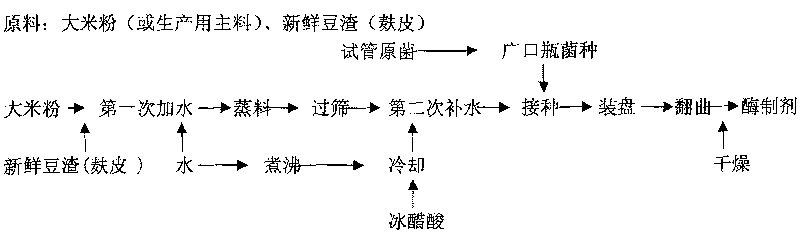

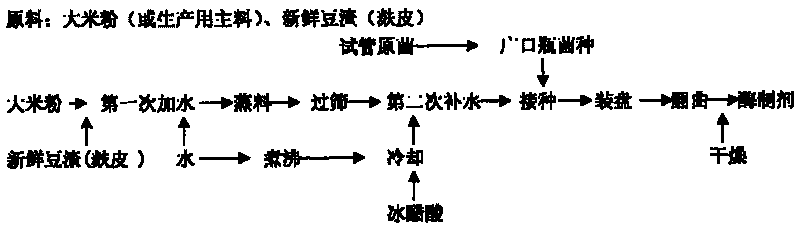

[0039] The preparation of embodiment 1 compound enzyme preparation

[0040] Aspergillus oryzae (Aspergillus oryzae) Huyao 3.042 (collection number AS3.951 of the Chinese Academy of Sciences) is used as a cultured strain of enzyme preparation;

[0041] Take 100 kg of raw rice flour, mix it with fresh bean dregs of equal weight, make the water weight percentage of the mixed raw material constant at 45%-50%, cook at normal pressure for 30-45min, sieve with a 3-5 mesh sieve, and replenish water , the amount of water replenishment is based on the ambient air humidity ≥ 90%, and glacial acetic acid is added at the same time. The amount of glacial acetic acid added is 1‰ of the weight of rice flour. According to the weight of raw materials, the inoculation amount of Shanghai Brewed 3.042 is 3‰, and the thickness of koji material is 2-3 cm, control the temperature at 32-35°C, cultivate for 17 hours to turn the koji, make the koji for 22 hours, and dry it with air at a temperature of 4...

Embodiment 2

[0042] The preparation of embodiment 2 compound enzyme preparations

[0043] Aspergillus oryzae (Aspergillus oryzae) 3.040 is used as the cultured strain of enzyme preparation;

[0044] Take 100 kg of raw rice flour, mix it with fresh bean dregs of equal weight, make the water weight percentage of the mixed raw material constant at 45%-50%, cook at normal pressure for 30-45min, sieve with a 3-5 mesh sieve, and replenish water , the amount of water replenishment is based on the ambient air humidity ≥ 90%, and glacial acetic acid is added at the same time. The amount of glacial acetic acid added is 1‰ of the weight of rice flour. According to the weight of raw materials, the inoculation amount of Shanghai Brewed 3.040 is 5‰, and the thickness of koji material is 2-3 cm, control the temperature at 32-35°C, cultivate the koji for about 19 hours, make the koji for 25 hours, and dry it in natural air for 3-4 days to obtain a compound enzyme preparation. It has been determined that t...

Embodiment 3

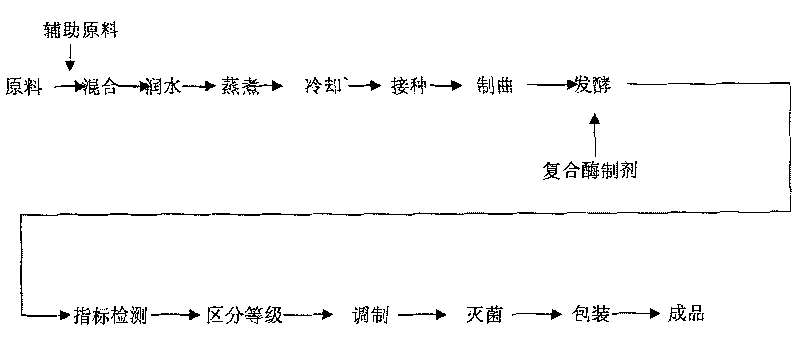

[0049] Application of embodiment 3 compound enzyme preparation in fermented bean curd production

[0050] After the soybeans are screened, soaked, refined, filtered, boiled, and pulped, and the white base is made (the process before the white base is a general process), 0.5% AS3.25 Wutongqiao Mucor is inoculated for early fermentation, and the temperature is controlled at 18-30°C, turn the koji when the needle-like germination of mucormyces appears on the surface in the middle, make the koji for 36-48 hours to mature, then add salt to marinate the unstrained spirits for 3-5 days, and then add 1.5% by weight of dry raw materials according to Example 1 or 2 Mix the prepared compound enzyme preparation with other commonly used auxiliary materials for fermented bean curd, such as white wine, pepper, pepper, etc., and mix it with salted cabbage, and then add other auxiliary materials such as bean curd, etc. Ferment for half a year or control the temperature at 28°C to 32°C for abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com