Method for treating condensation waste water for producing imidacloprid and resourcized recovering its imidazolidine

A recovery method, imidazolidine technology, applied in the field of condensation wastewater treatment, can solve problems such as waste of resources, failure to be recycled, pollution, etc., and achieve the effect of realizing waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

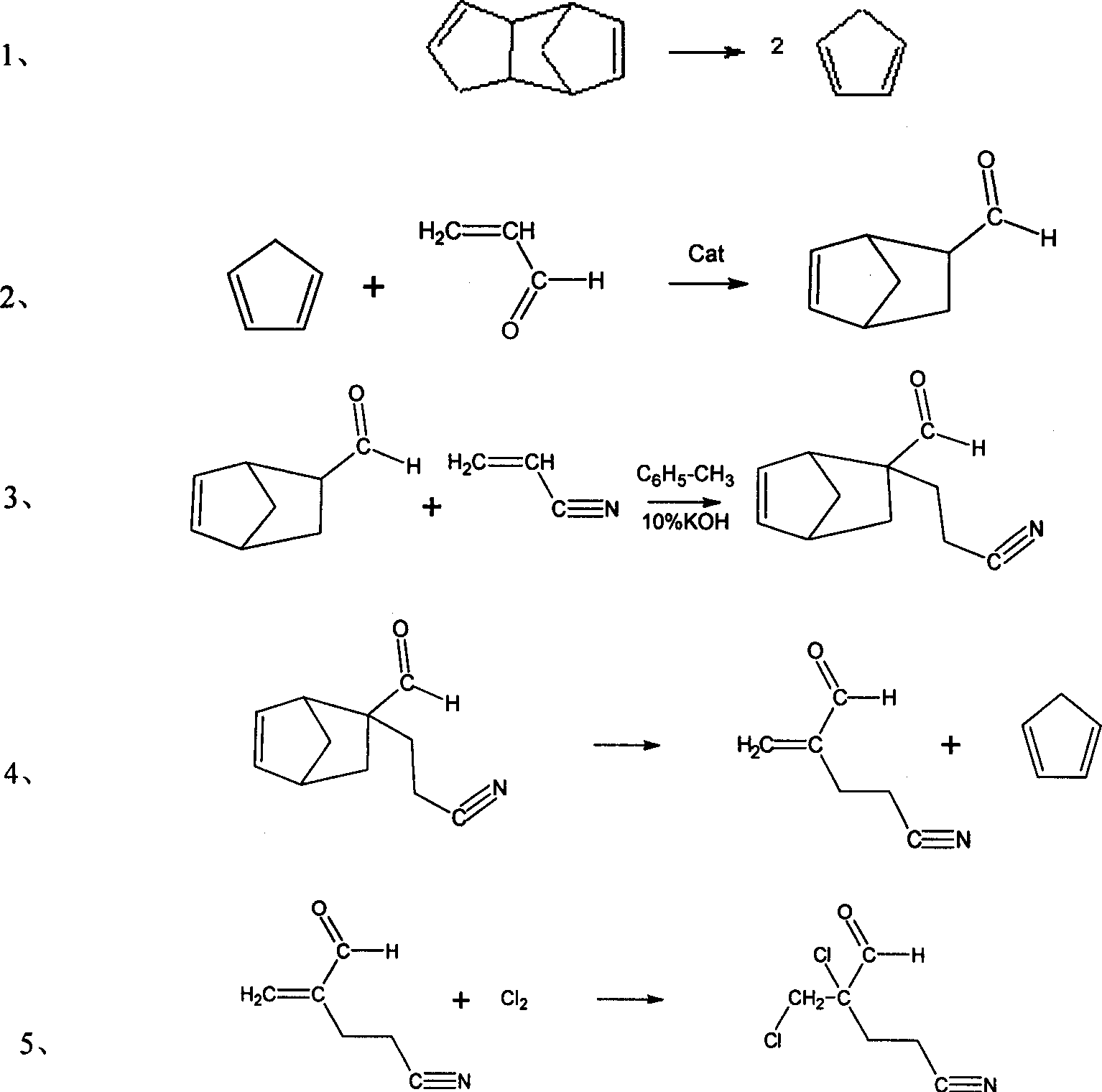

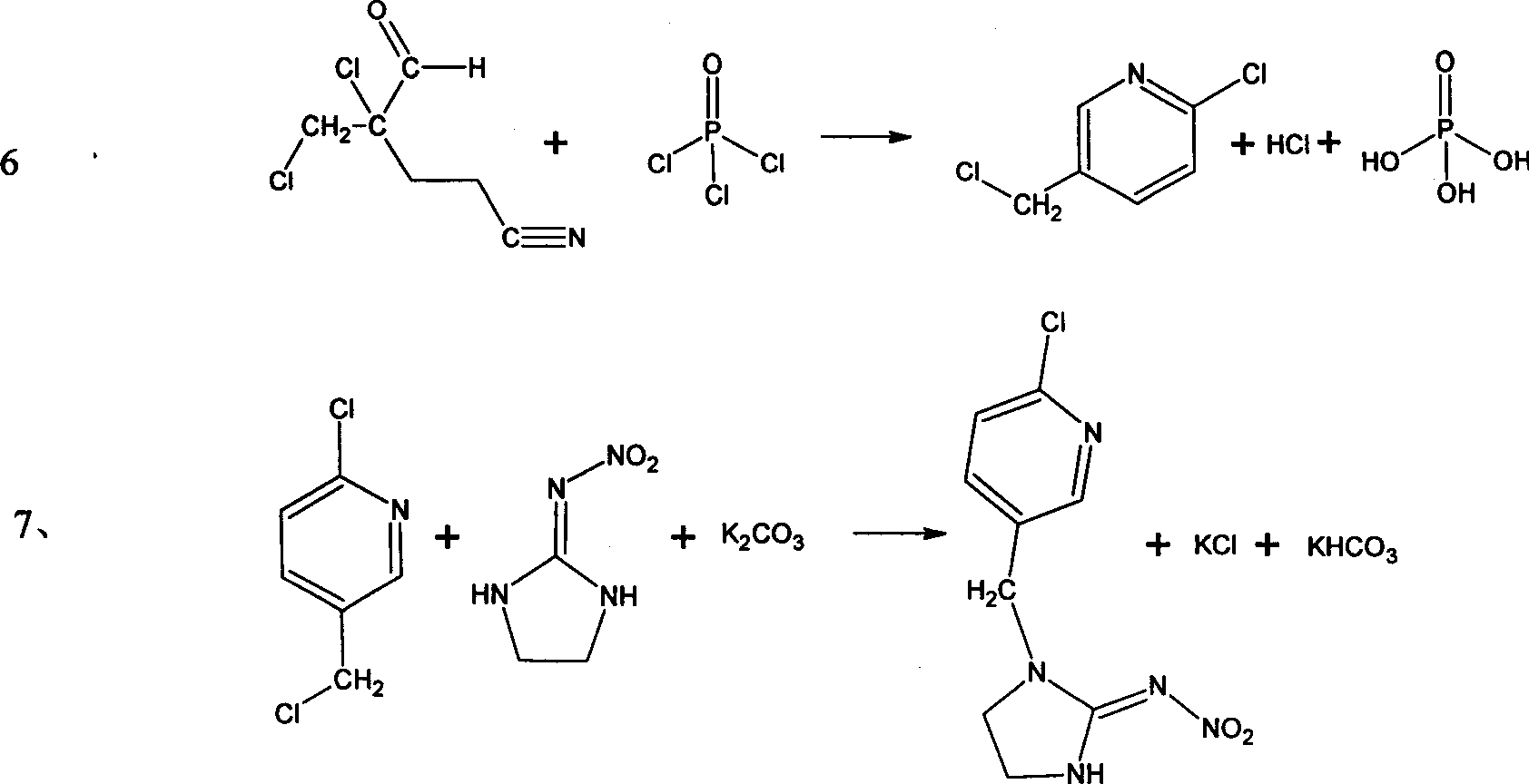

Method used

Image

Examples

Embodiment 1

[0022] Fill each 20mL (about 15g, dry weight) of JX101 and NDA-7 resins into two adsorption columns with insulation jackets (Ф20×250mm).

[0023] Take 550mL of light yellow condensation wastewater in the production of imidacloprid, filter it, and aerate it for half an hour. Upper column solution COD Cr is 35680mg / L, and the imidazolidine content is 18600mg / L. At room temperature (25°C), 400ml of the upper column solution was passed through the JX101 resin column at a flow rate of 40mL / h. The water produced by the primary adsorption was colorless, and the imidazolidine content dropped to 16800mg / L, COD Cr Drop to 33400mg / L, PH is about 4.

[0024] After neutralizing the first-stage adsorption water with solid NaOH, take 150ml of the upper column liquid and pass it through the NDA-7 resin column at a flow rate of 20mL / h. After the second-stage adsorption water is mixed, the measured imidazolidine content drops to 263mg / L , COD Cr Dropped to 1576mg / L.

[0025] After the seco...

Embodiment 2

[0030] Pack 200mL (about 150g, dry weight) of NDA150 and NDA-7 resins into two adsorption columns (Ф35×500mm) with insulation jackets respectively.

[0031] Take 5L of light yellow condensation wastewater in the production of imidacloprid and filter it, then aerate for half an hour. Upper column solution COD Cr It is 36410mg / L, and the content of imidazolidine is 19100mg / L. At room temperature (25°C), 4.4L of the upper column solution was passed through the NDA150 resin column at a flow rate of 460mL / h. The first-stage adsorption water was colorless, and the measured imidazolidine content dropped to 17900mg / L, COD Cr Drop to 34830mg / L, PH is about 4.

[0032] After the primary adsorption water was neutralized with solid NaOH, 1.6L of the upper column liquid was passed through the NDA-7 resin column at a flow rate of 200mL / h. After the secondary adsorption water was mixed, the imidazolidine content was measured to drop to 963mg / h L, COD Cr Dropped to 3514mg / L.

[0033] Aft...

Embodiment 3

[0038] Pack 300mL (about 225g, dry weight) of NDA150 resin into an adsorption column with a thermal insulation jacket (Ф35×500mm), and 400mL (about 300g, dry weight) of NDA-7 resin are evenly packed into two columns with a thermal insulation jacket In the glass column (Ф35×500mm).

[0039] Take 6L of light yellow condensation wastewater in the production of imidacloprid and filter it, then aerate for half an hour. Upper column solution COD Cr is 35190mg / L, and the imidazolidine content is 18300mg / L. At room temperature (25°C), 4.4L of the upper column liquid was passed through the NDA150 resin column at a flow rate of 400mL / h. Cr Reduced to 34160mg / L, PH is about 4.

[0040] After neutralizing the first-stage adsorption water with solid NaOH to neutrality, take 1.6L of the upper column liquid and pass through two NDA-7 resin columns in turn at a flow rate of 180mL / h, take out the second-stage adsorption water, and measure the COD Cr It is 512mg / L and contains almost no imi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com