Solid cone spray nozzle

A full cone, nozzle technology, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of continuous casting billet shell cracks, increase the risk of clogging, etc., achieve uniform fluid distribution, reduce the risk of clogging, and improve Effect of flow cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

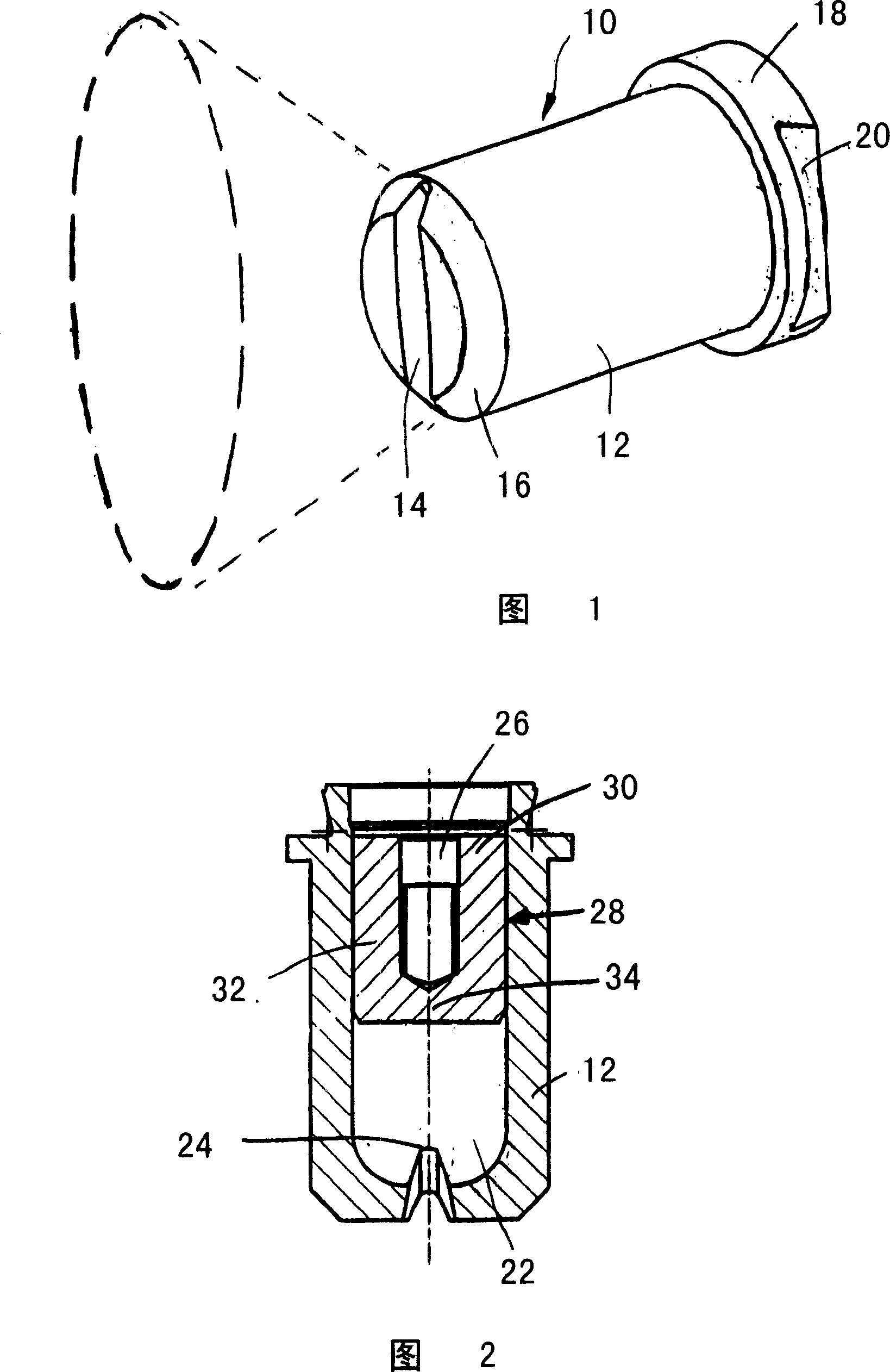

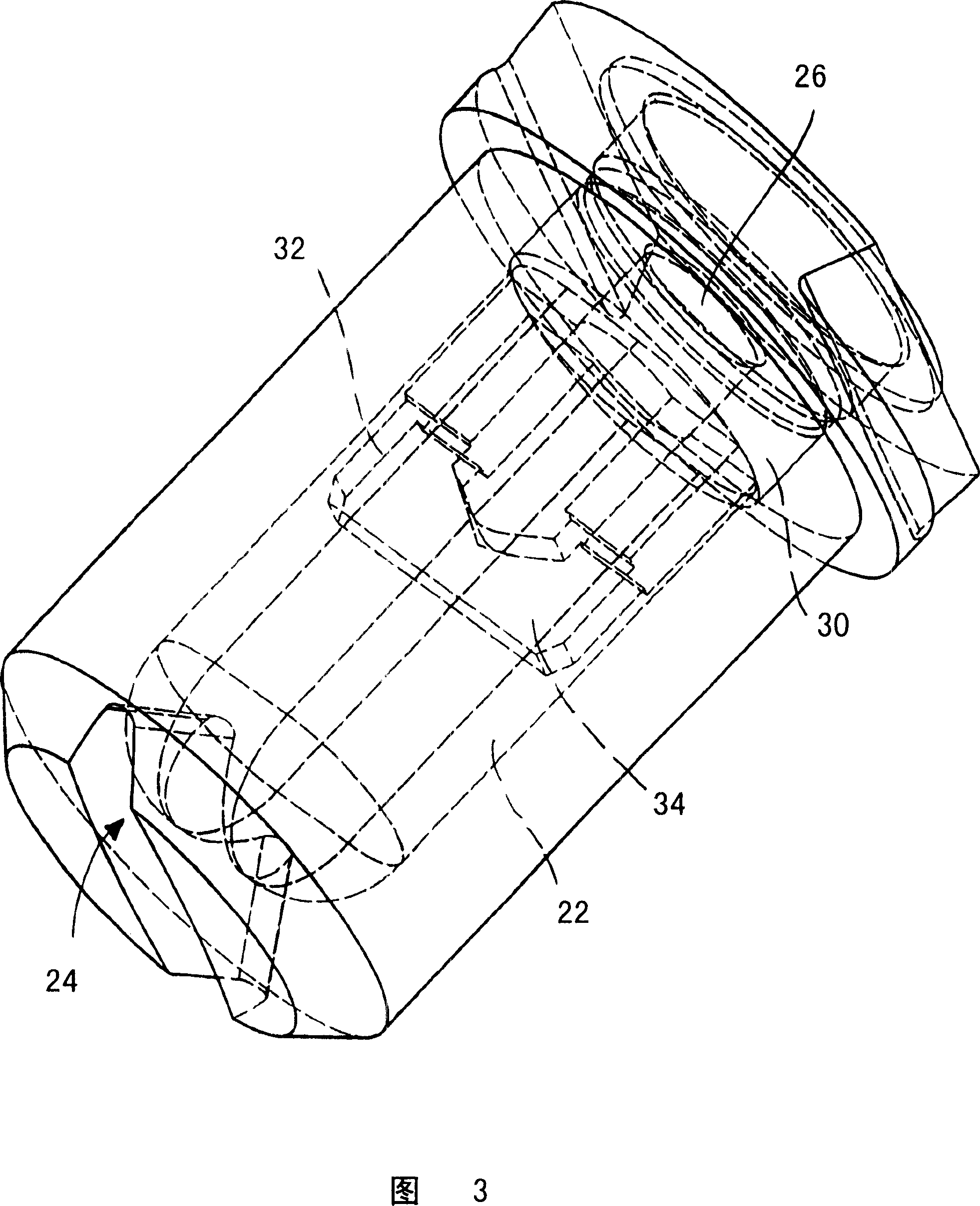

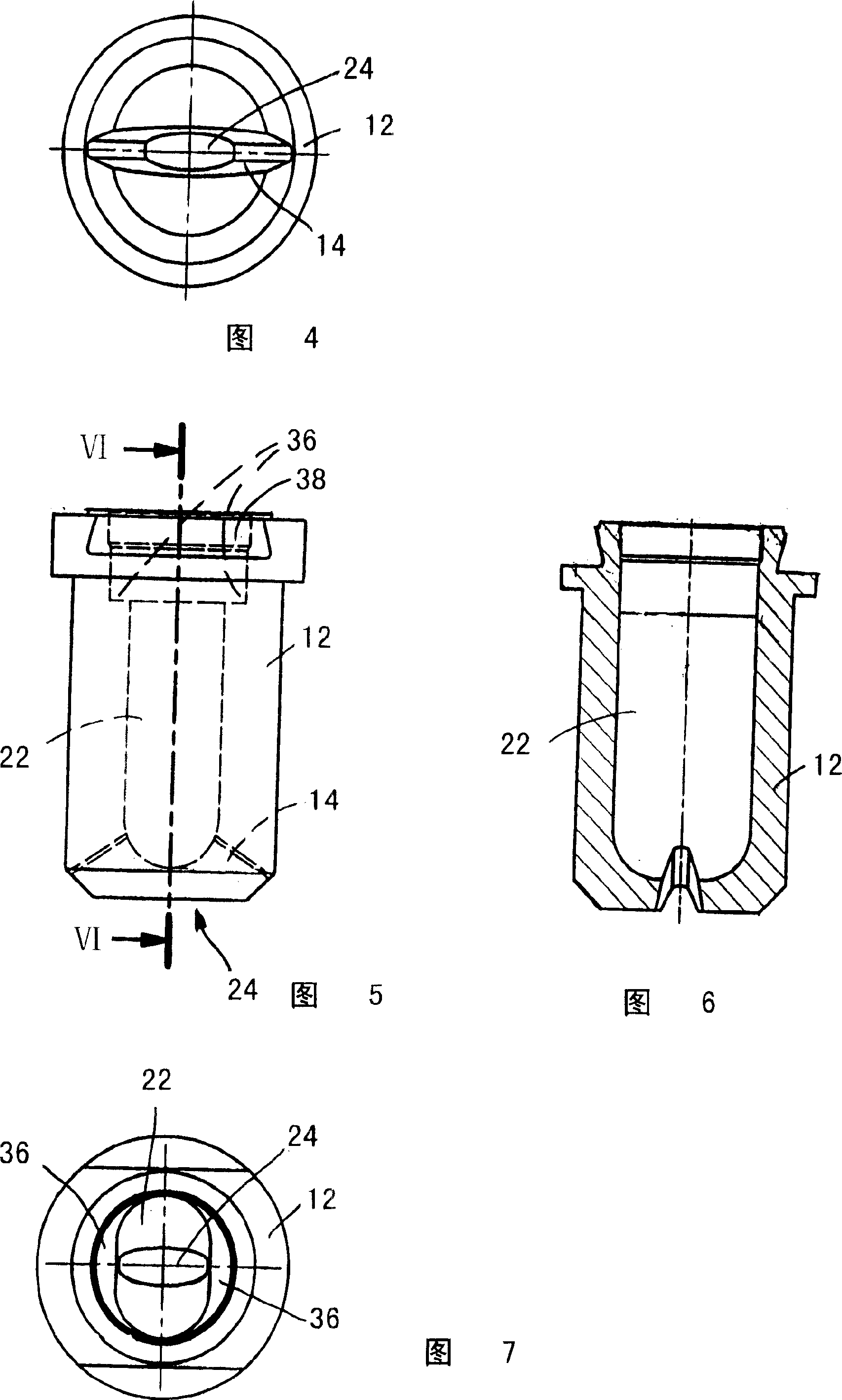

[0062] The perspective view of FIG. 1 shows a spray nozzle 10 according to the invention with an integral spray body housing 12 . An outlet cone 14 can be seen in an end face of the nozzle housing 12 , which adjoins an oval outlet opening, which is not visible in FIG. 1 . The discharge cone 14 has an essentially likewise elliptical cross-sectional shape, wherein this cannot be easily seen in the illustration in FIG. Discharge the side end of the cone.

[0063] The spray body housing 12 is generally cylindrical and has a circumferential flange 18 at its rear end, the end for connection to a fluid line. The flange 18 is laterally provided with flattened sections 20 , of which only one flattened section is visible in the illustration in FIG. 1 , but it covers the opposite identical flattened section.

[0064] A spray cone produced by spray nozzle 10 is indicated by a dashed line in FIG. 1 . As can be seen, the spray cone has a uniform oval shape.

[0065] The jet body housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com