Ammonia synthesis purge gas isobaric recovery tower

A technology of purge gas and recovery tower, applied in steam condensation, ammonia preparation/separation, dispersed particle separation, etc., can solve the problems of affecting ammonia gas dissolution, high tray temperature, low recovery rate, etc., and improve the concentration of ammonia water. , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

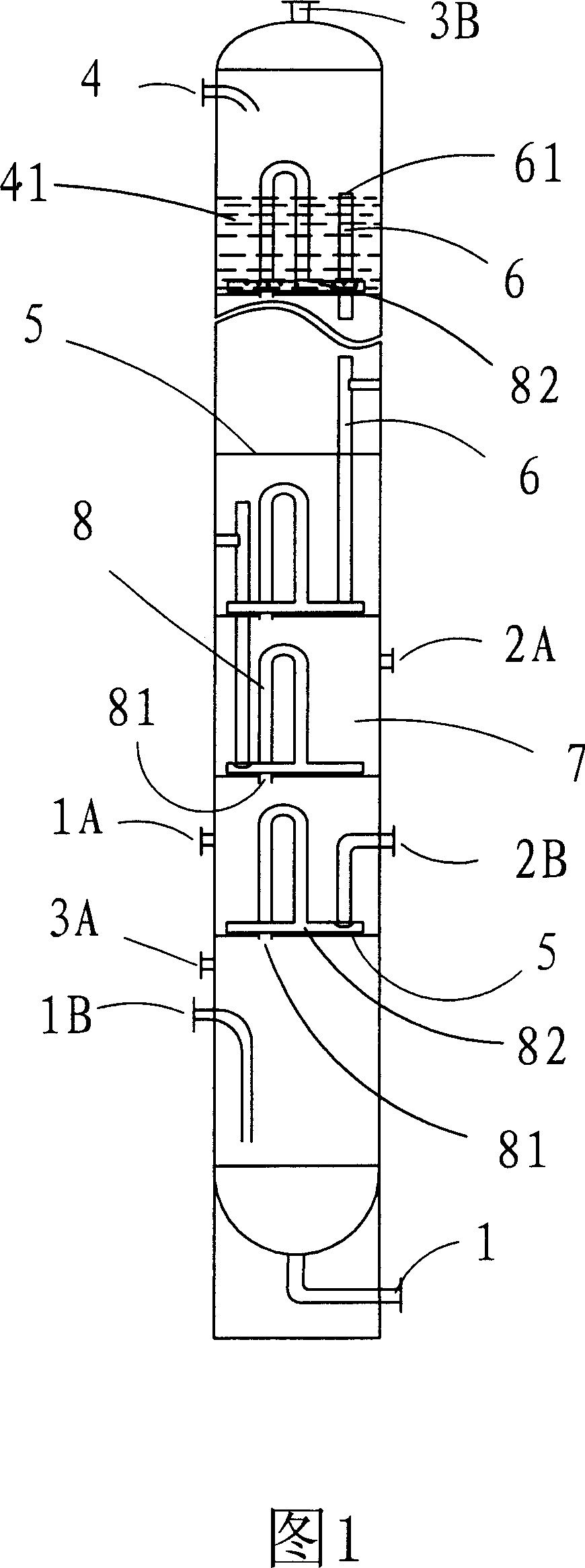

[0024] The serial numbers in the figure are: ammonia water discharge pipe 1, ammonia water outlet 1A on the first floor, ammonia water inlet 1B on the bottom layer, ammonia water outlet 2A on the second floor, ammonia water inlet 2B on the first floor, bleed gas inlet 3A, bleed gas outlet 3B, soft water inlet 4, Liquid layer 41, tray 5, downcomer 6, downcomer nozzle 61, second layer 7, gas riser 8, gas riser nozzle 81, bottom pipe 82; absorption unit layer 10, heat exchanger 11, heat exchange The cooling water inlet 11a of the heat exchanger, the cooling water outlet 11b of the heat exchanger, the downcomer left partition 12, the downcomer right partition 121, the bubble cap 13, the tower wall 14, the gas-lifting partition 15, the gas-lifting channel 151, and the heat exchange unit Layer 16, ascending air passage 17, ascending air passage opening 171, positioning arm 172, casing 18, air outlet 181.

[0025] Fig. 2 shows a partial cross-sectional structure of the whole tower of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com