Heat tube radiating device

A heat dissipation device and heat pipe technology, which is applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problems of high heat density, small air flow, low heat distribution of radiators, etc., and achieve large heat distribution area, Improved heat exchange rate and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

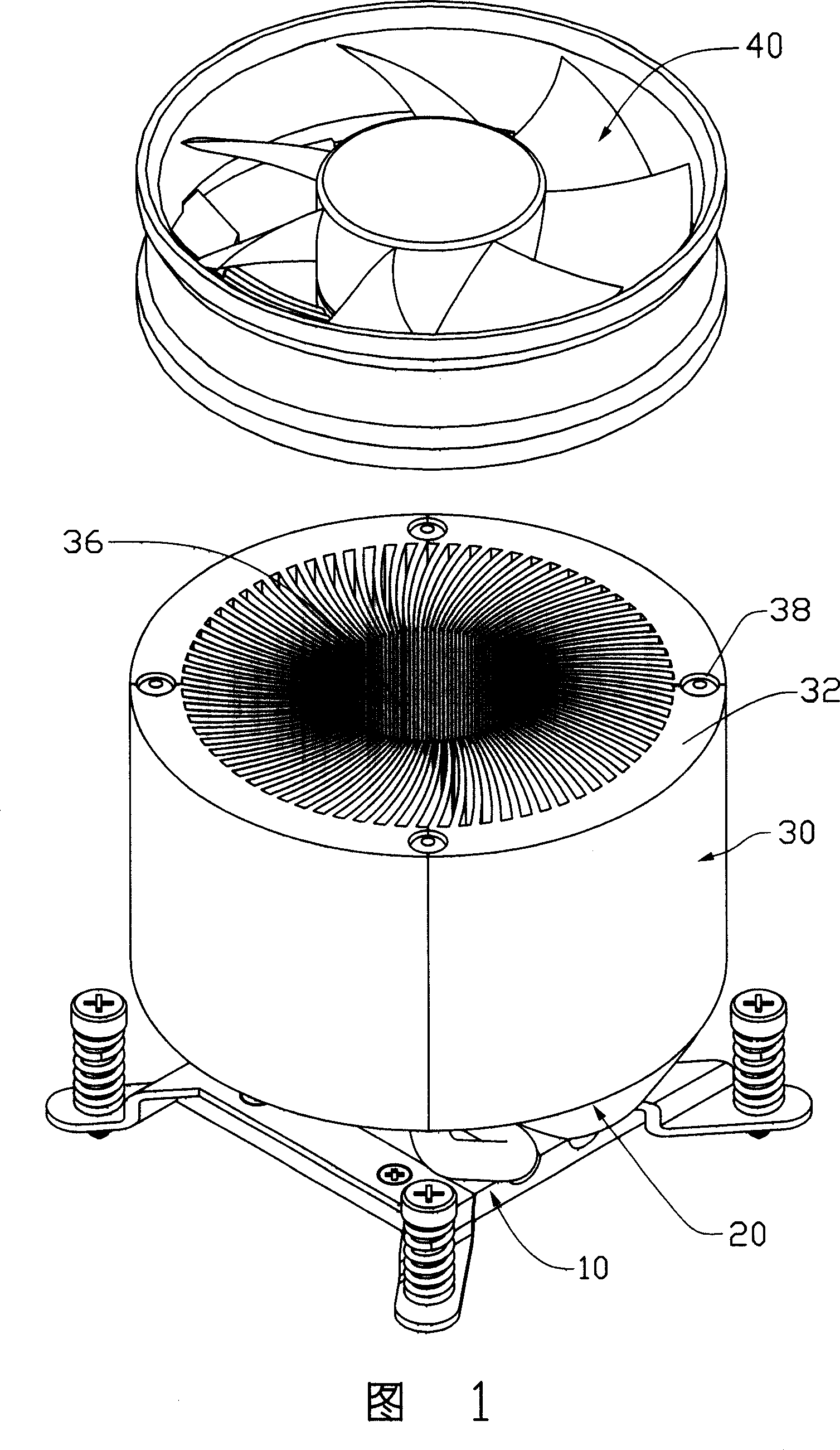

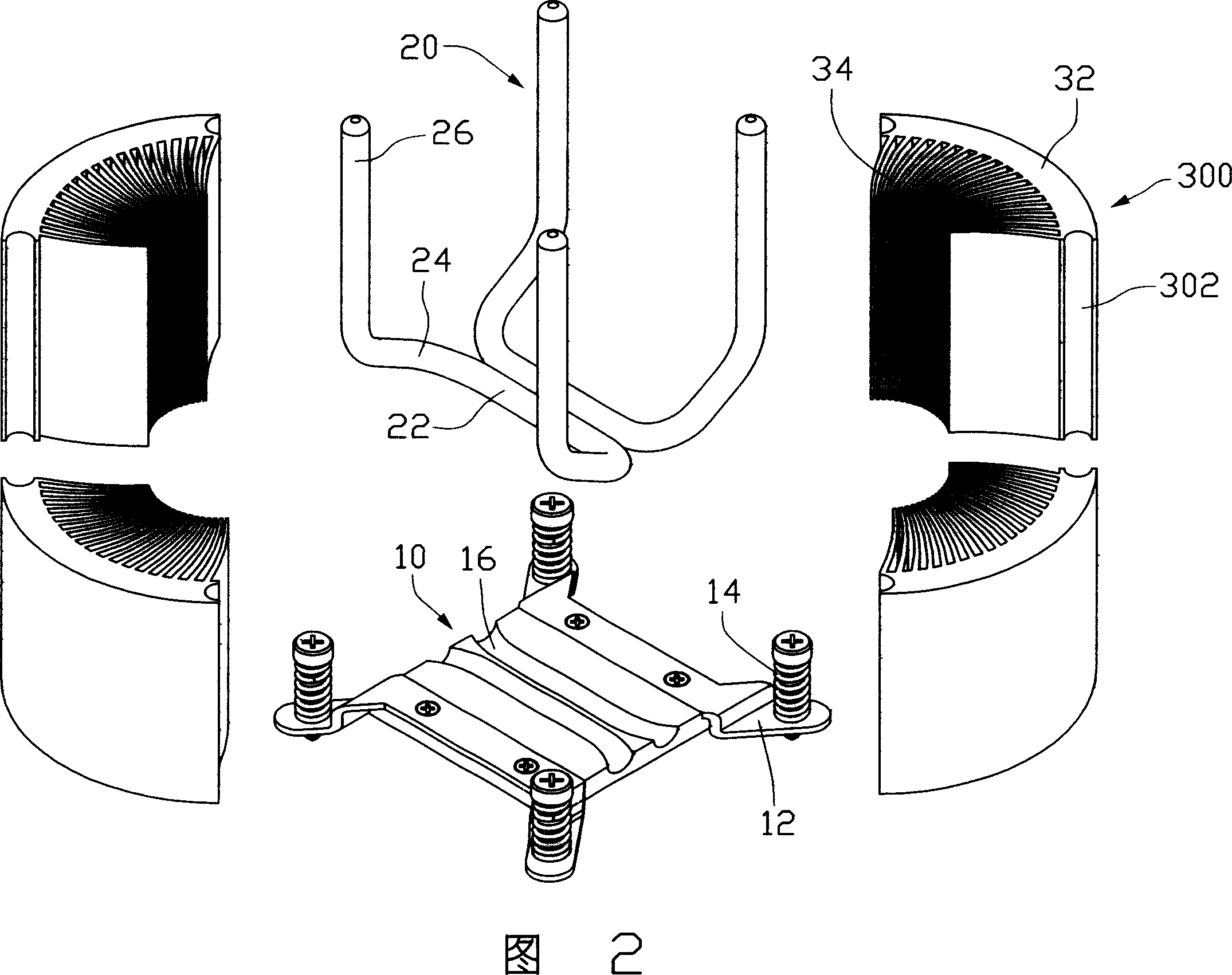

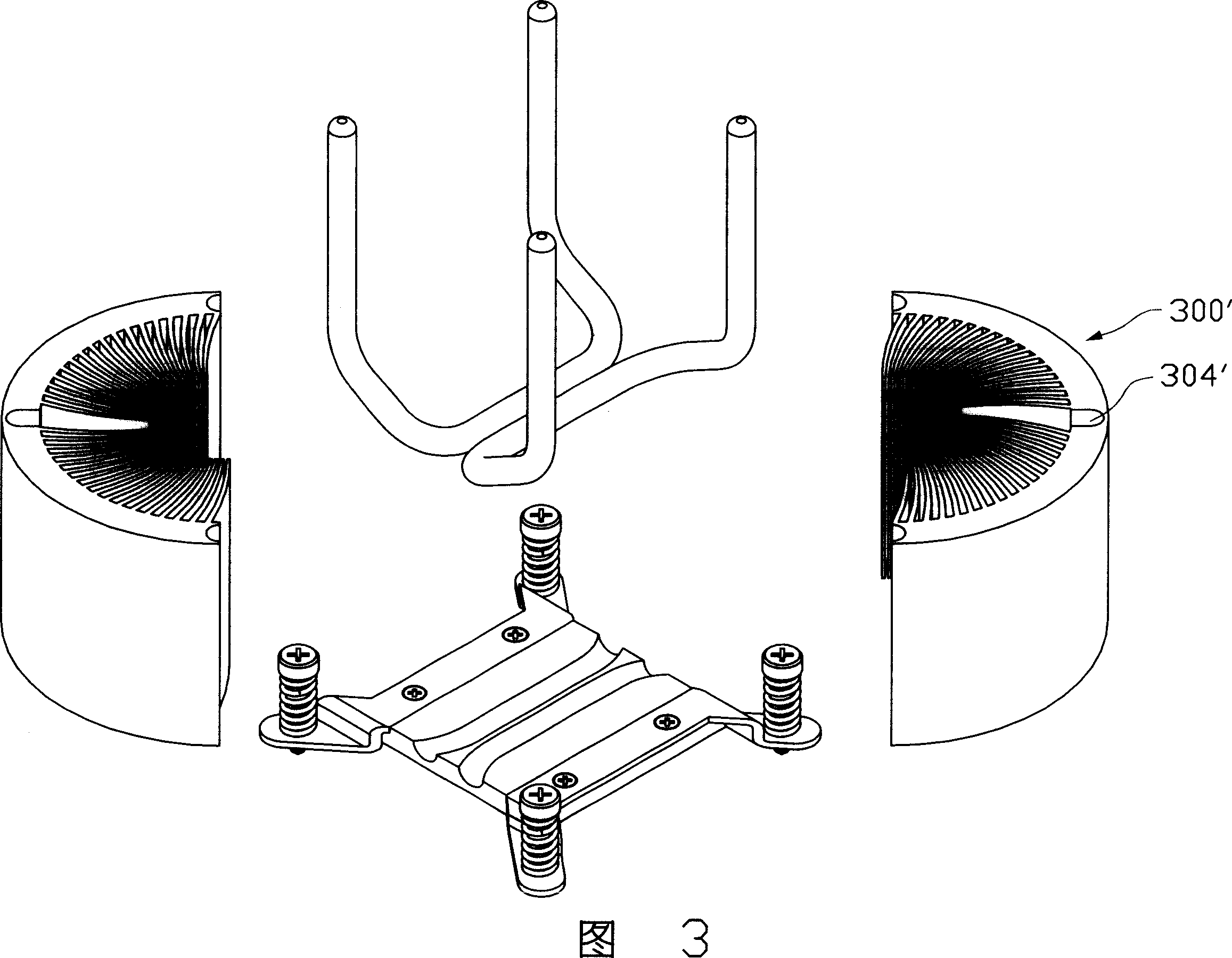

[0014] The heat pipe heat dissipation device of the present invention is used to install on heat-generating electronic components such as a central processing unit (not shown in the figure) to dissipate heat. Please refer to Fig. 1 and Fig. 2, the first embodiment of the heat pipe cooling device of the present invention comprises a substrate 10, two heat pipes 20 which are attached to the substrate 10 and whose two ends extend vertically upwards, and a cylindrical tube connected to the heat pipe 20 Radiator 30.

[0015] The base plate 10 is roughly rectangular, and its four corners are provided with fixing feet 12. Screws and springs are pre-assembled on the fixing feet 12 to fix the fixing piece 14 with a cooling device. The two grooves 16 are substantially parallel.

[0016] The heat pipe 20 is roughly three-dimensional U-shaped, which has an evaporation portion 22 accommodated in the groove 16 of the substrate 10, an inclined portion 24 extending obliquely outward and upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com