Disperse dye mixture and its product

A technology of disperse dyes and mixtures, applied in the directions of organic dyes, dyeing, textiles and papermaking, etc., to achieve the effect of good homochromaticity, excellent lifting ability and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

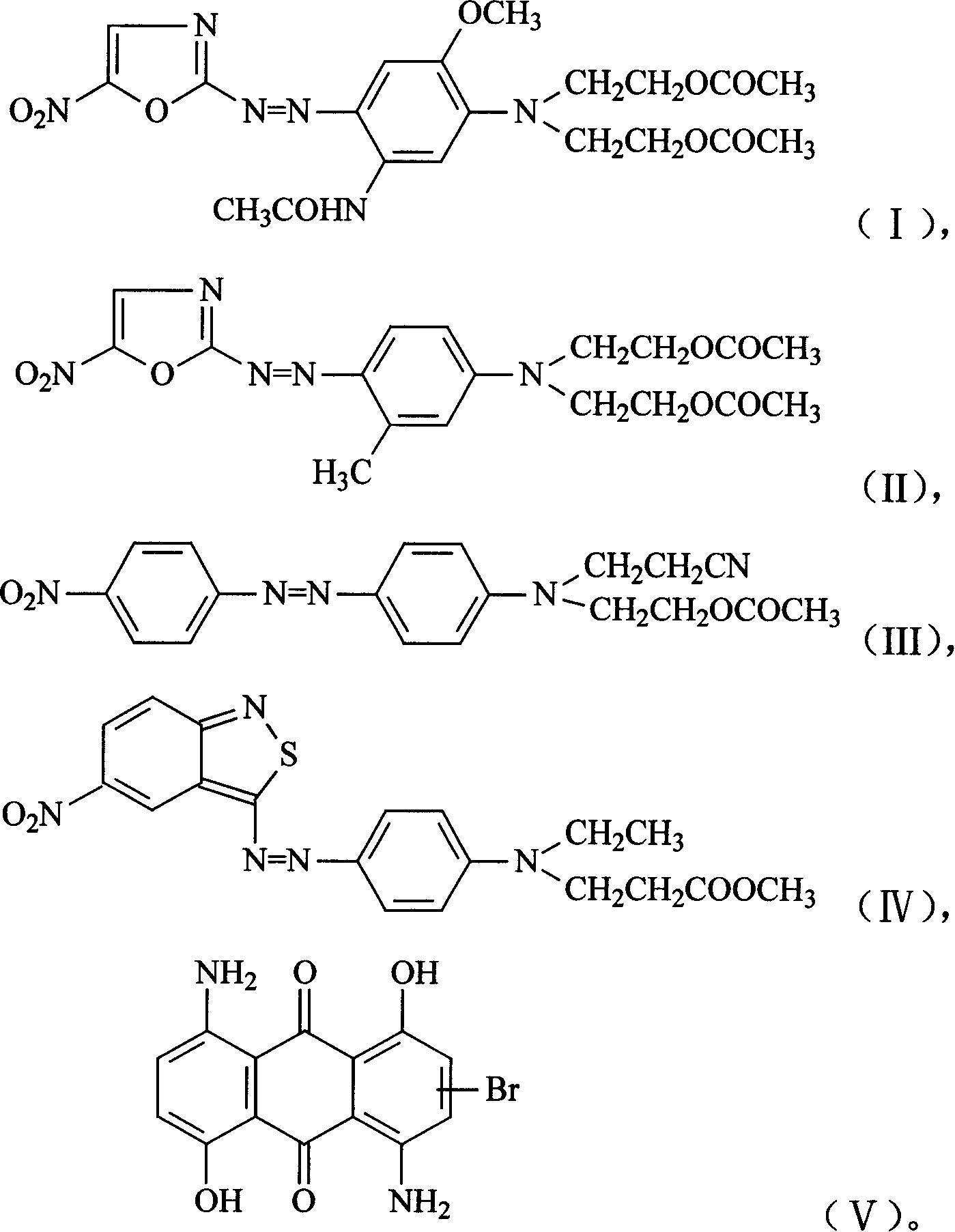

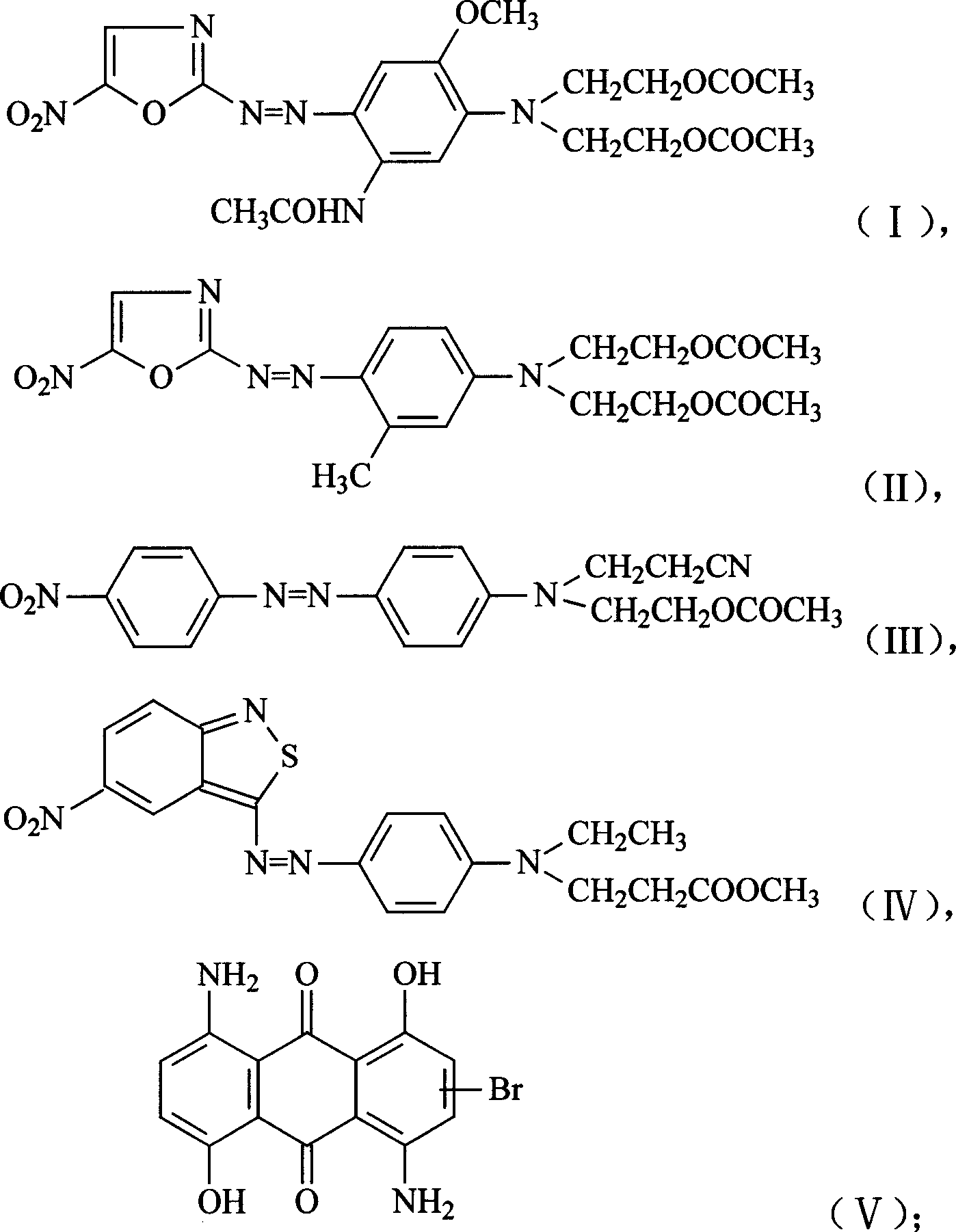

Image

Examples

Embodiment 1

[0023] 17 grams of dye A, 10 grams of dye B, 15 grams of dye C, 7 grams of dye D, and 2 grams of dye E were mixed together to obtain a dye mixture whose shade was navy blue.

Embodiment 2

[0025] In the dye mixture that embodiment 1 obtains, add 60 gram dispersants MF, 120 gram pure waters, carry out micronization (do dispersion treatment) with sand mill then, spray dry again, obtain the goods of disperse dye mixture, its shade is navy blue.

Embodiment 3

[0027] The dye commercial product containing 15.1 g of dye A, the dye commercial product containing 8.7 g of dye B, the dye commercial product containing 19.1 g of dye C, the dye commercial product containing 5.3 g of dye D and the dye commercial product containing 1.8 g of dye E Mixing, the product of the disperse dye mixture is directly obtained, and the total weight ratio of the total weight of the five dyes to the auxiliary agent is 1:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com