Hydraulic lifting stern platform

A working platform, hydraulic lifting technology, applied in the direction of slipway, dry dock, lifting device, etc., can solve the problems of uneven load, serious inclination of the working platform, different oil pressure loss, etc., to achieve convenient and safe operation, shortened production cycle, Avoid the effect of misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

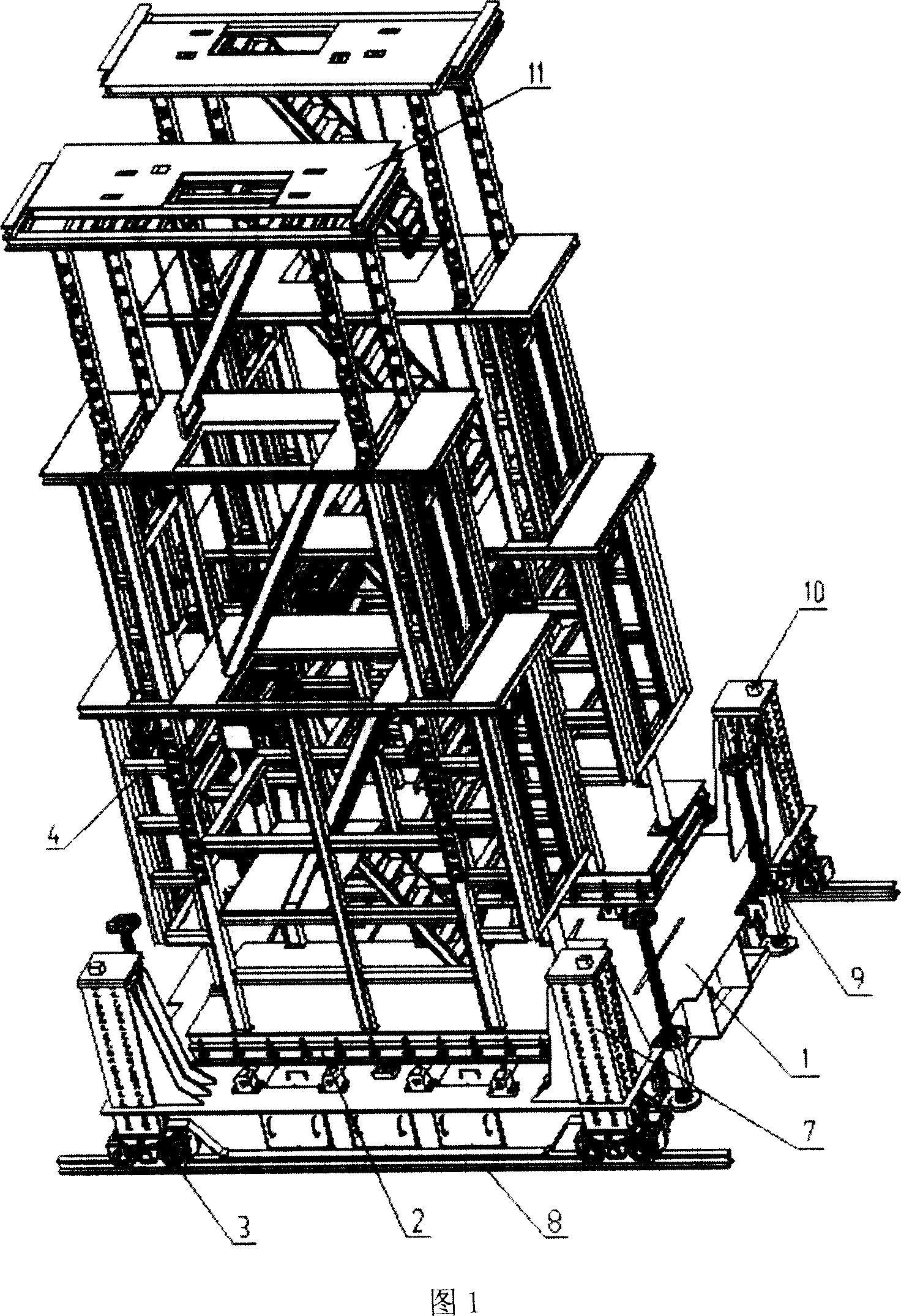

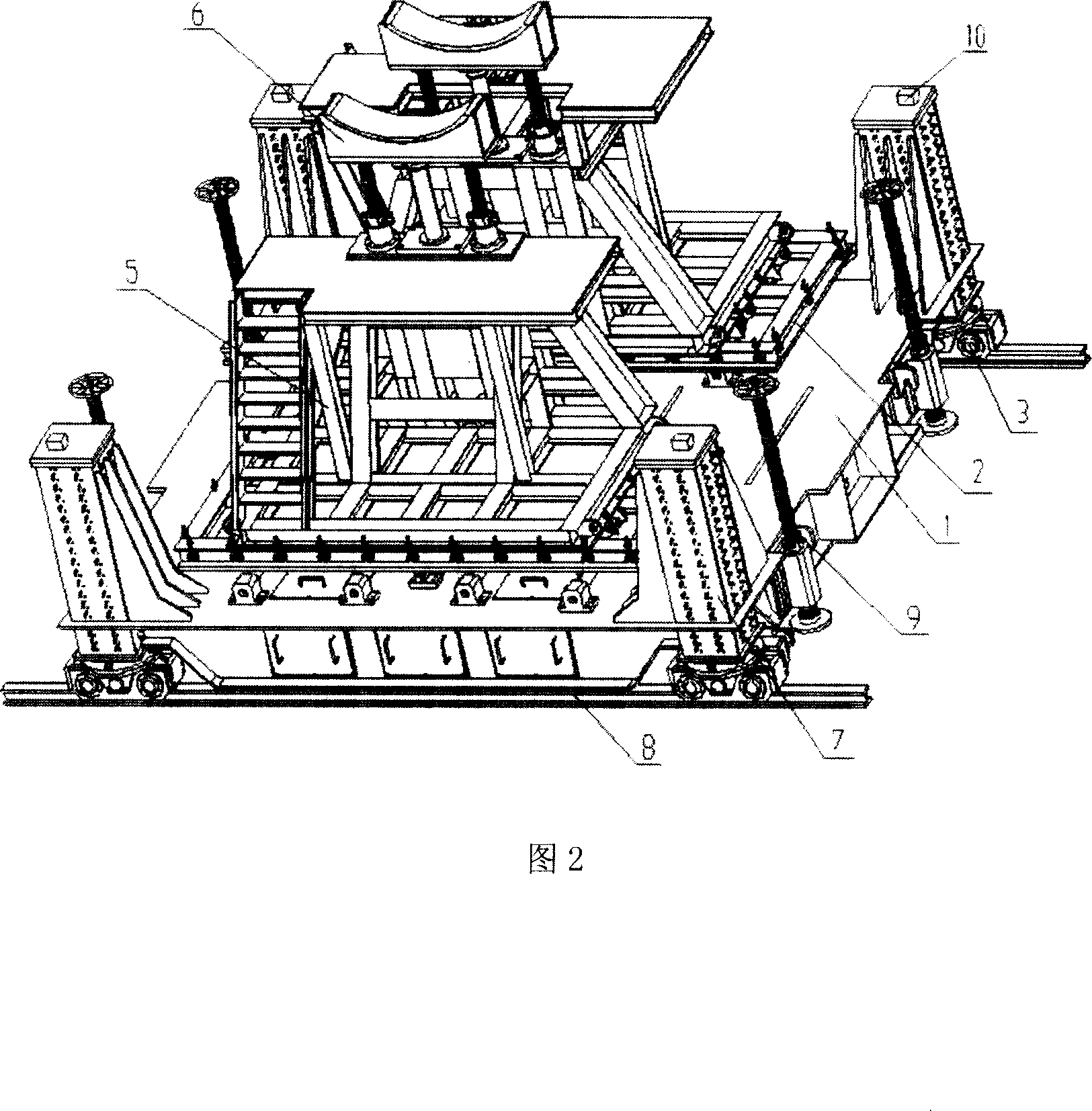

[0016] As shown in Figures 1-2, the stern hydraulic lifting work platform of the present invention includes: a work platform 1, a plane slide table 2, a rolling wheel 3, a rudder blade stand 4, and a propeller stand 5. The working platform 1 is the main body of the present invention, and the plane sliding table 2 is installed on the upper plane of the working platform 1, and the whole stern hydraulic lifting work platform is supported by the roller wheel 3, and the rudder blade stand 4 and the propeller stand 5 are respectively installed on the plane slide table 2 superior.

[0017] The rudder blade is placed on the working platform 1 and in the middle of the rudder blade stand 4 on both sides, and the propeller is placed flat on the supporting block 6 of the propeller stand 5 . A main lifting hydraulic cylinder 7 is respectively installed on the four corners of the working platform 1, which can vertically displace the working platform 1 and play the role of vertically raising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com