Wafer grinding and cutting process

A cutting method and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of chipping before cutting, wafer scratches, wafer exposure, etc., to reduce scratches, The effect of avoiding scratches and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

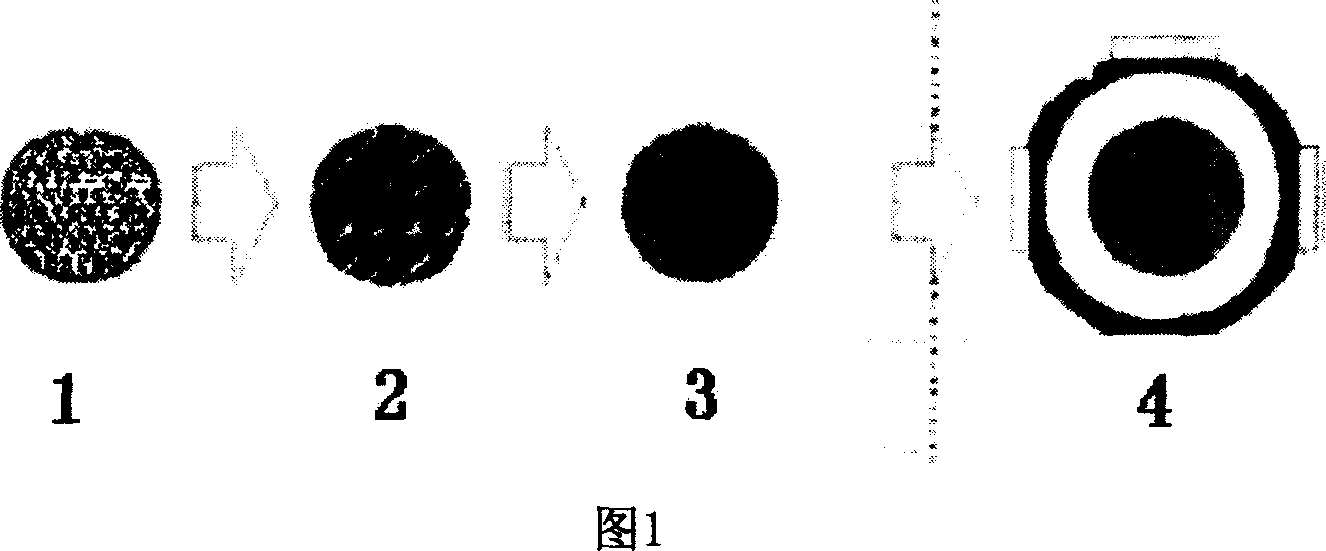

[0010] In the present invention, the existing normal ordinary wafer grinding and cutting process sequence is adjusted from 1-2-3 (①wafer film before grinding; Wafer film (3) before cutting (2) peeling after operation) to reduce chip scratches, crushing and chipping.

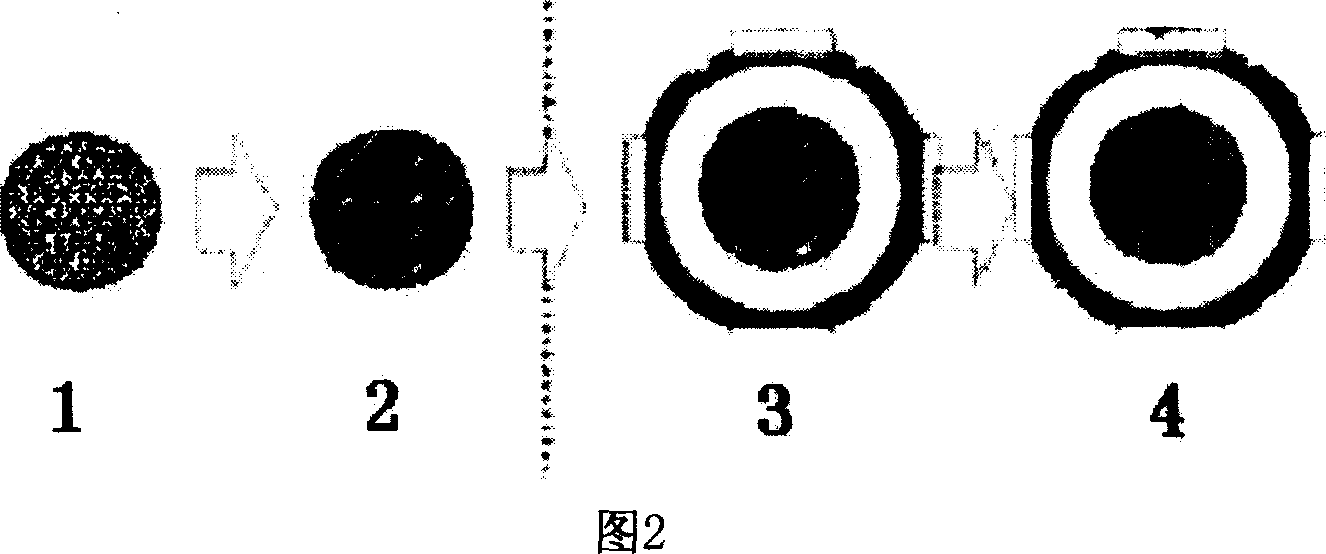

[0011] Therefore, concrete method steps of the present invention: (as shown in Figure 2)

[0012] 1. Before grinding, the wafer is first coated with a film and then ground;

[0013] 2. Paste the wafer on the bracket with adhesive tape before cutting the disc after grinding;

[0014] 3. After the wafer is pasted, the film is peeled off;

[0015] 4. The wafer after peeling off the film can be operated on the cutting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com