Ceramic tile cloth, prepressing and blank-pulling integrated mechanism

A ceramic tile and cloth technology, applied in ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of many production cycles, unpredictable, limited texture patterns, etc., to simplify cloth equipment, reduce manufacturing costs and maintenance costs , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure and working principle of the present invention will be further described below with reference to the drawings and embodiments.

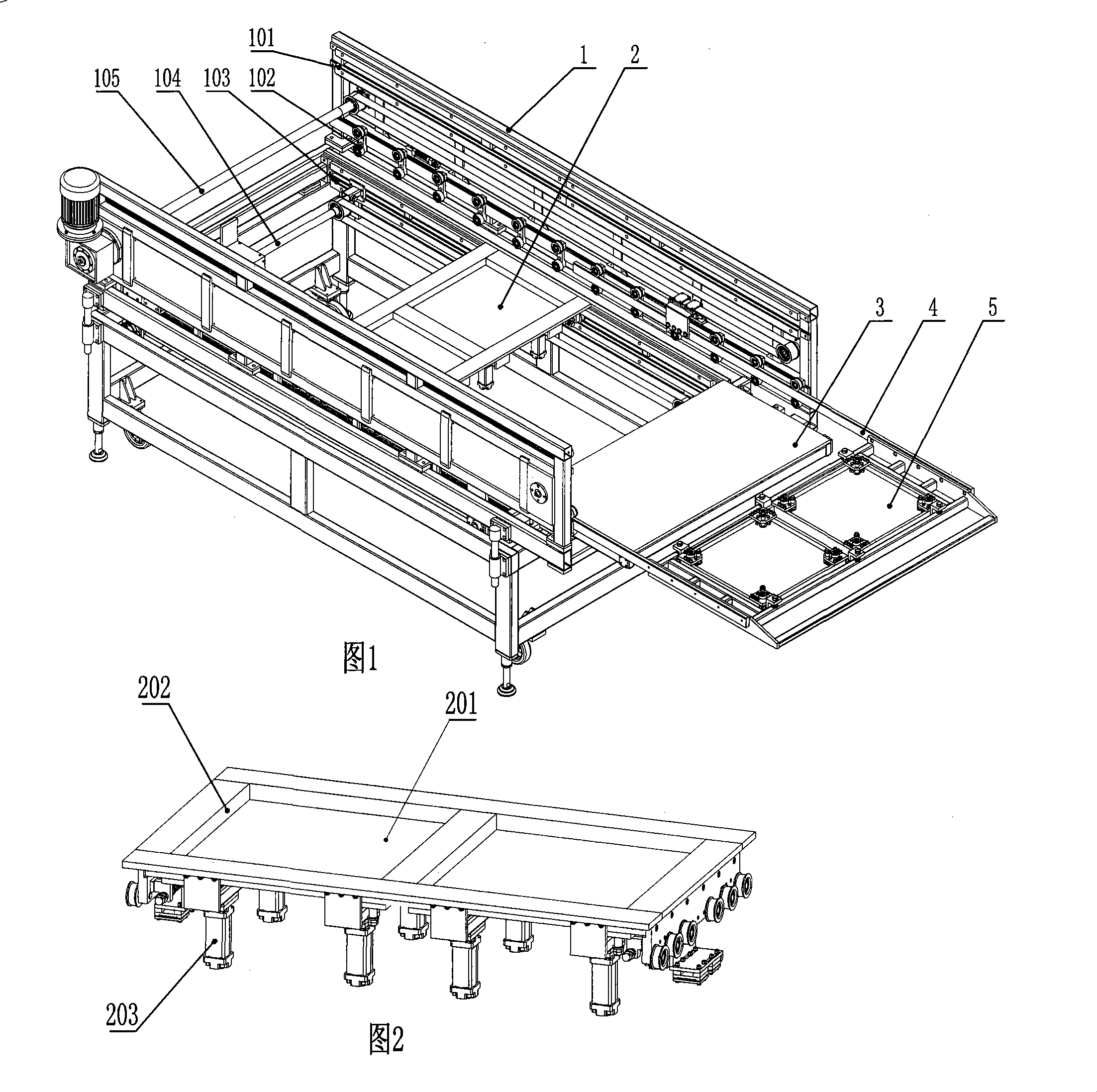

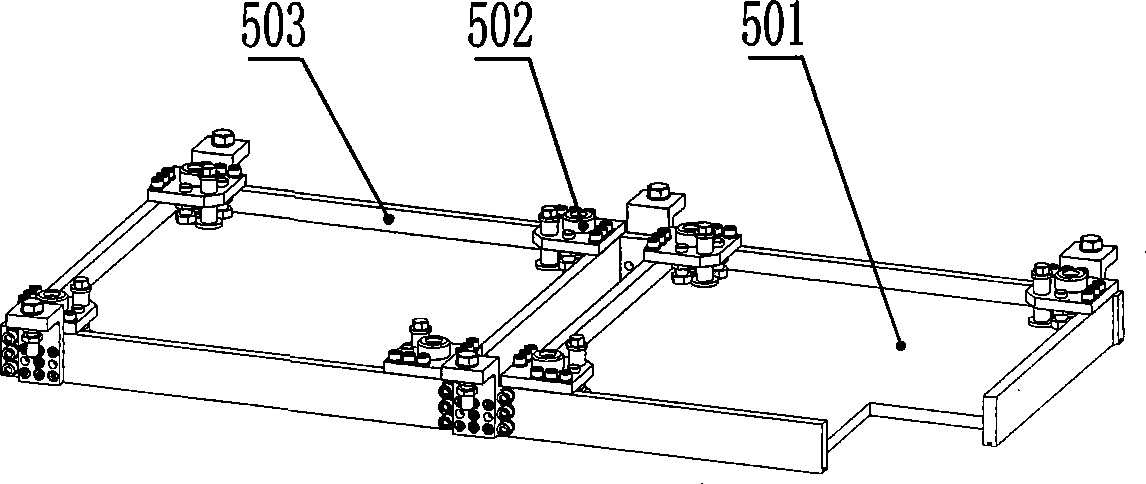

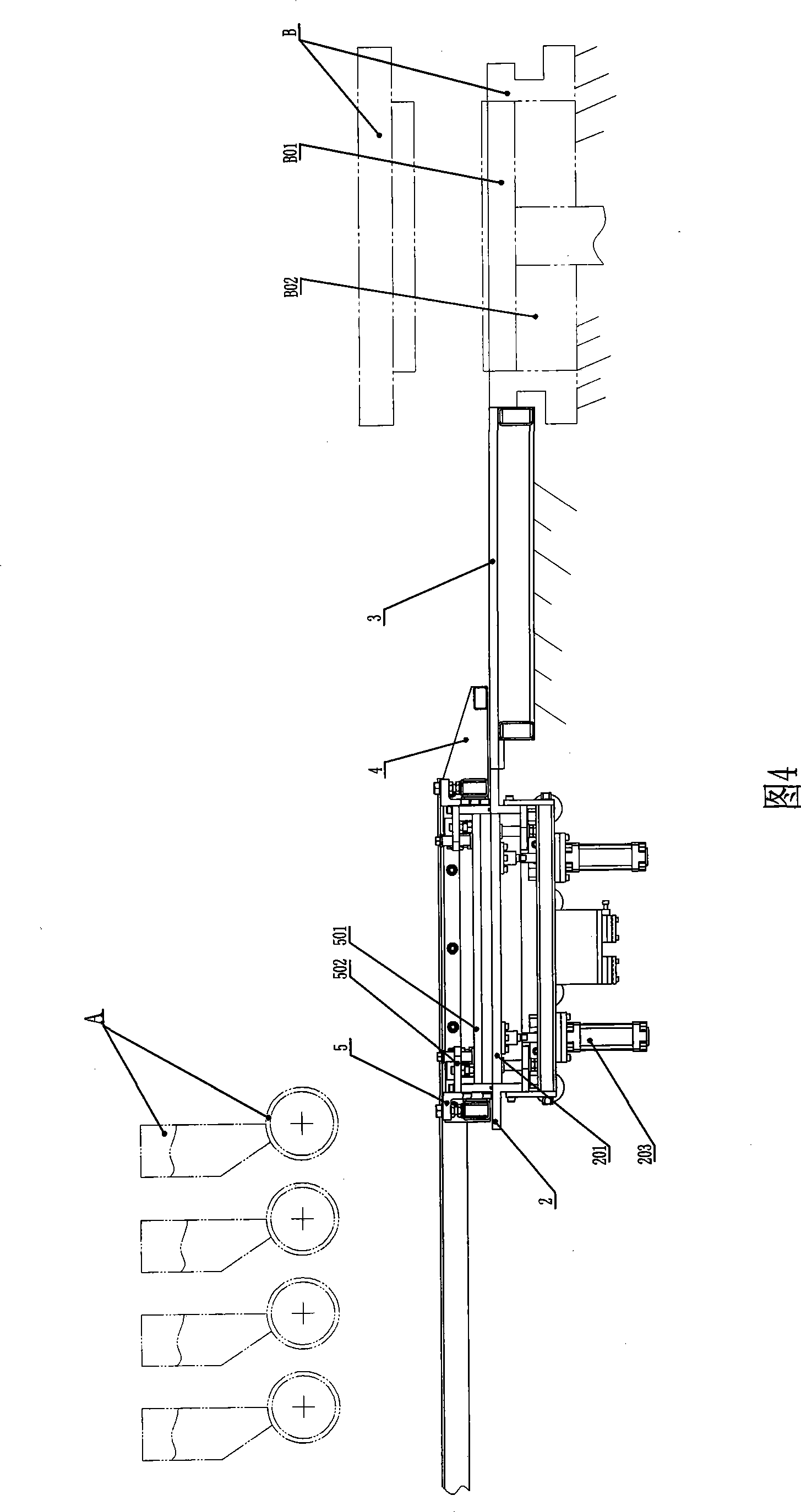

[0016] as attached Figure 1-6 As shown, a first driving device 104 and a second driving device 105 are installed on the main frame 1 of the present invention, and a first guiding device 101 , a second guiding device 102 and a third guiding device 103 are installed on both sides thereof.

[0017] Driven by the first drive device 104, the powder receiving platform mechanism 2 moves back and forth along the third guide device 103 or locks (such as permanently locking the disposable guide device guide device and the drive device), and the powder receiving chamber 202 in the middle accommodates The distributing mechanism A throws the powder to be distributed downwards, and the pressing device 203 at its lower part pushes the pressing plate 201 to press the distributed powder upwards at the powder pre-pressing station.

[0018] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com