Semifinished joint plate, joint plate, process for fabricating joint plate and heat exchanger

一种热交换器、接合板的技术,应用在间接换热器、热交换设备、换热器类型等方向,能够解决接合板不能有效地结合、元件数量增加等问题,达到避免热交换性能变差、防止短路、易于制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

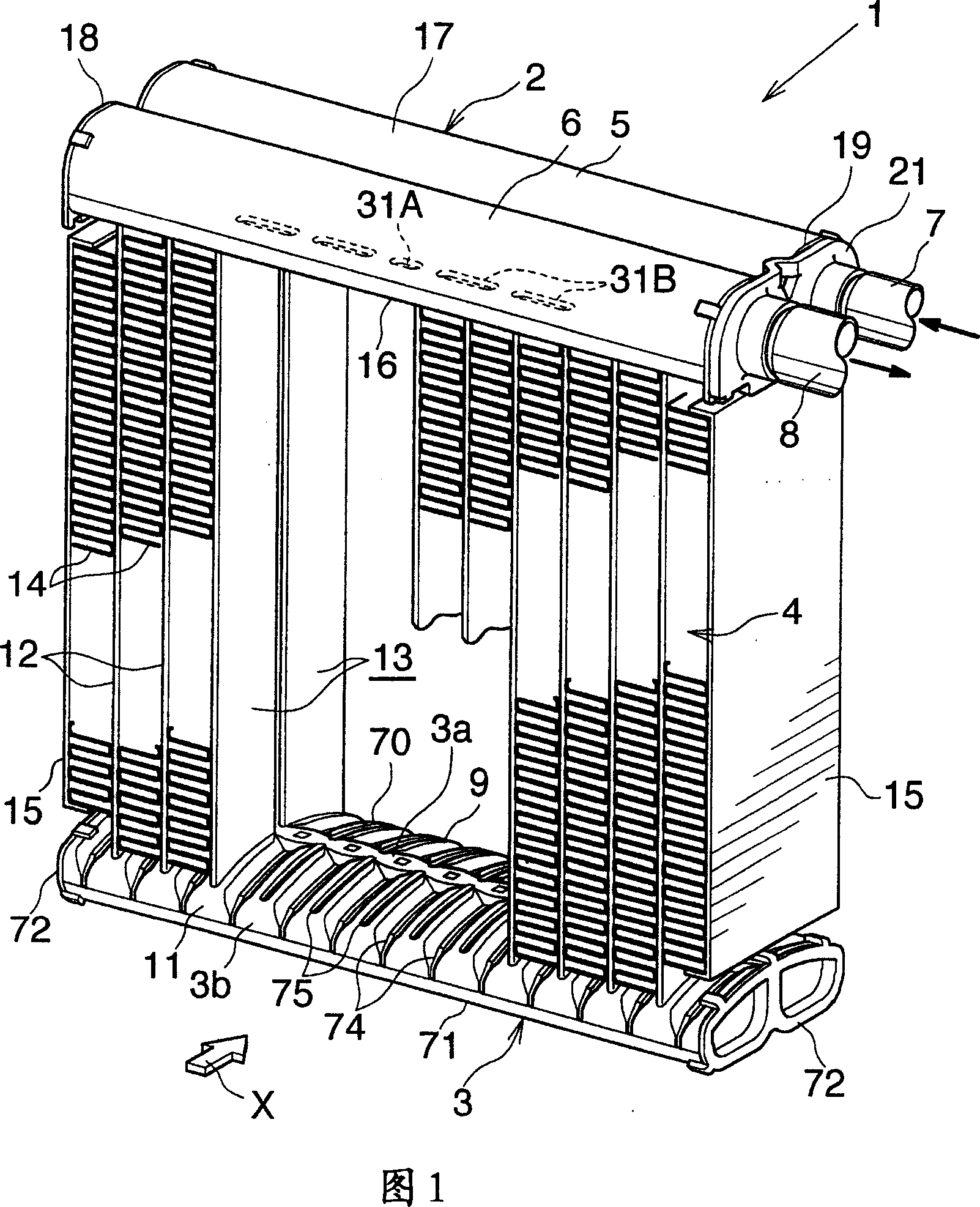

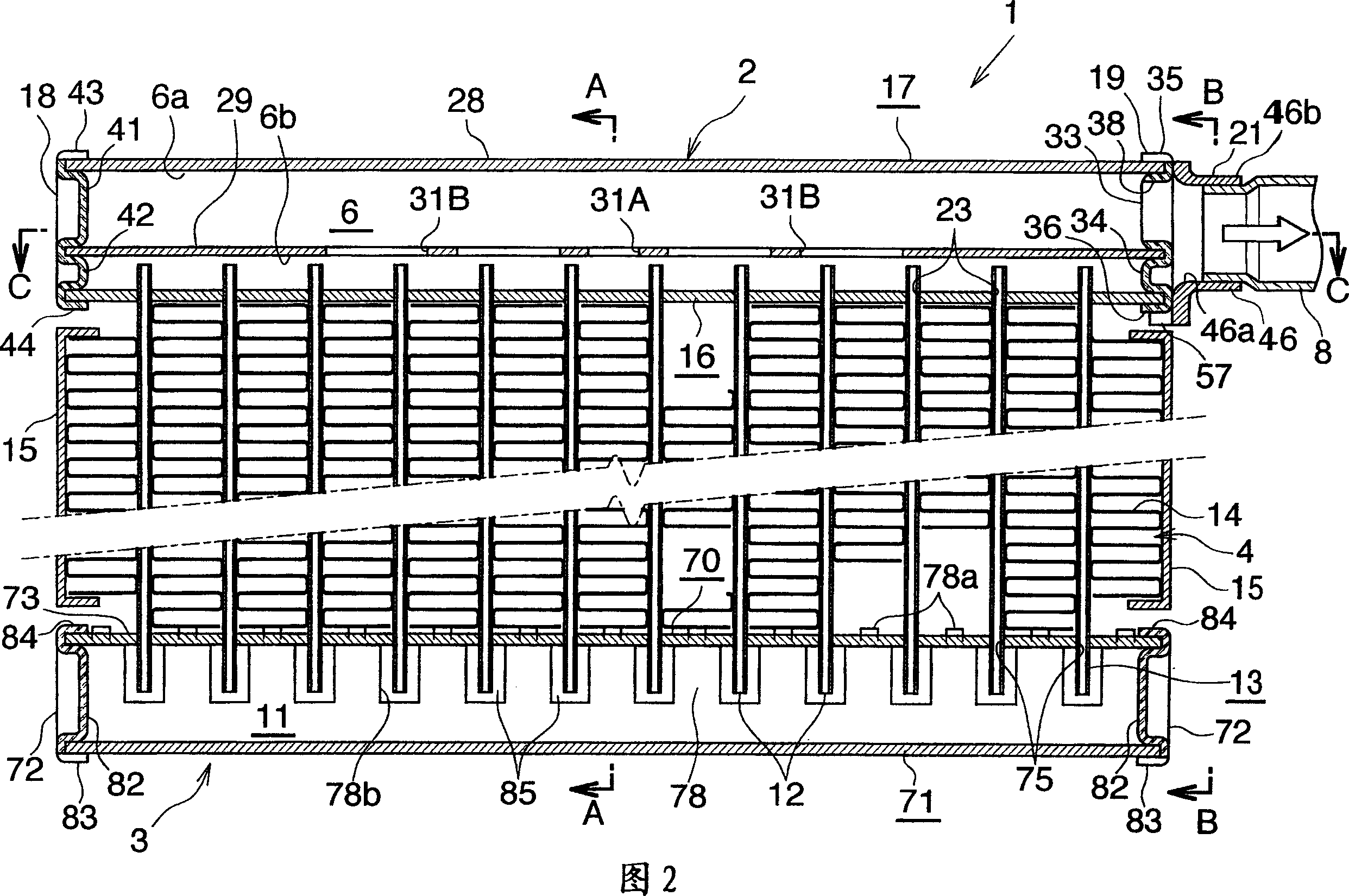

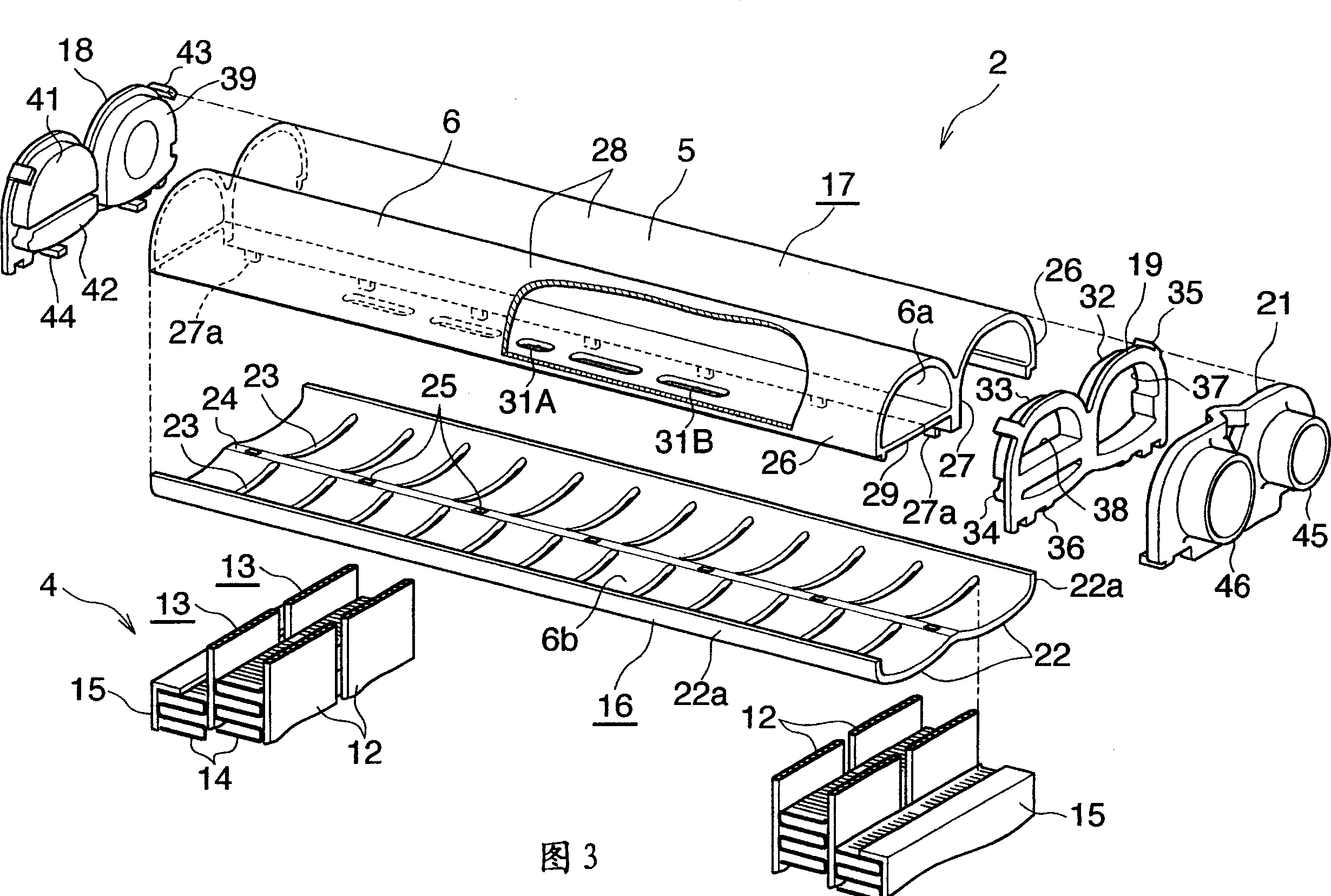

[0058] Embodiments of the present invention will be described below with reference to the drawings. This embodiment is an inventive heat exchanger used as an evaporator in a motor vehicle air conditioning unit.

[0059] 1 and 2 show the overall structure of an evaporator of a motor vehicle air conditioner to which a heat exchanger according to the present invention is applied, FIGS. 3-7 and 9 show the structure of main parts, and FIG. 8 shows a method of manufacturing a joint plate. Furthermore, Figure 10 shows how the refrigerant flows through the evaporator.

[0060] 1 and 2 show an evaporator 1 for an air conditioner in which a chlorofluorocarbon refrigerant is used. The evaporator 1 includes an aluminum refrigerant inlet-outlet tank 2 and an aluminum refrigerant diversion tank 3 arranged vertically spaced apart, and a heat exchange core 4 arranged between the two tanks 2 , 3 .

[0061] The refrigerant inlet-outlet box 2 includes a refrigerant inlet header 5 arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com