Stator for annular generator

A stator and ring-shaped technology, applied in the direction of magnetic circuit shape/style/structure, winding insulation shape/style/structure, winding conductor shape/style/structure, etc., can solve problems such as influence and prolongation of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

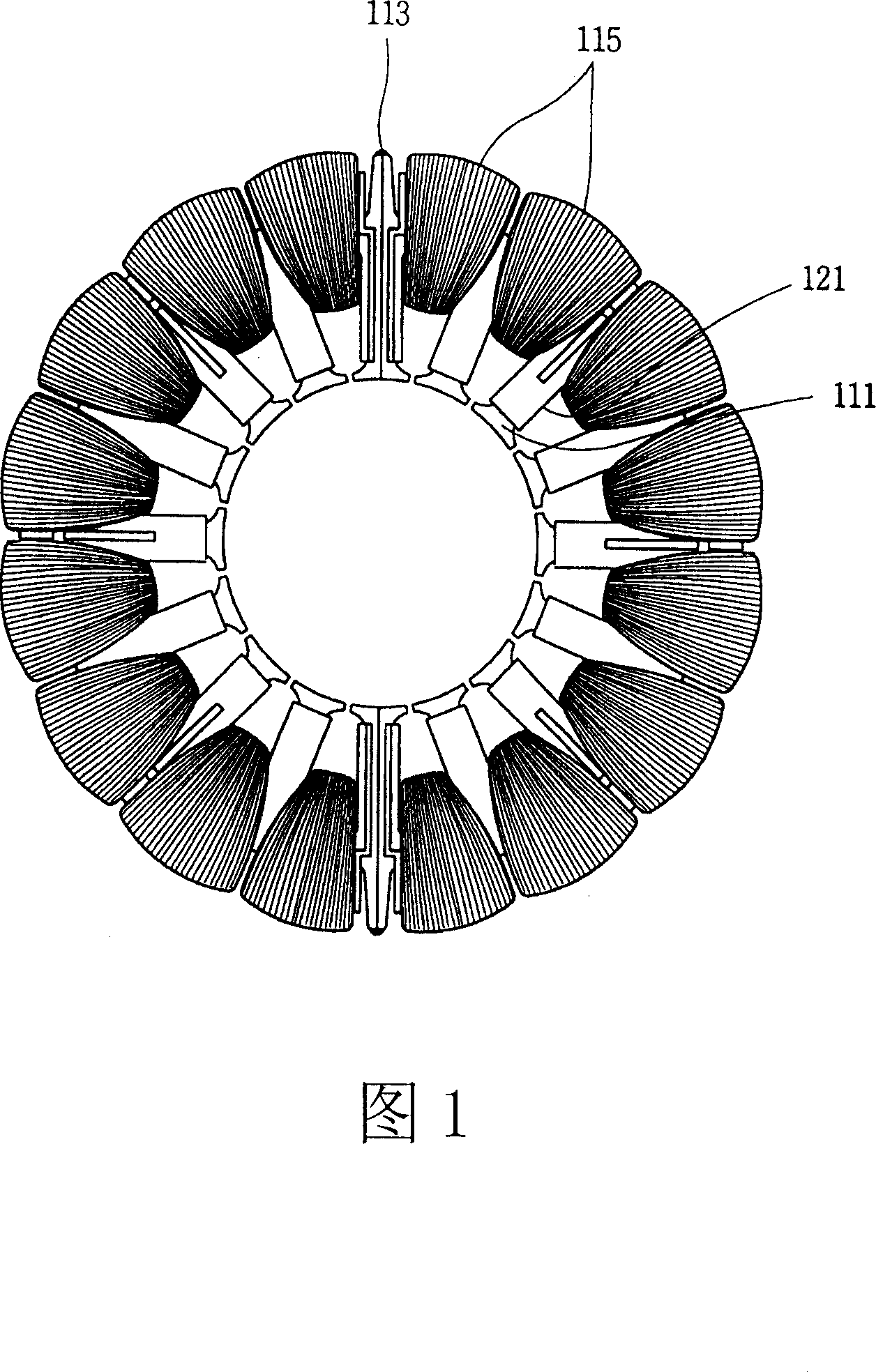

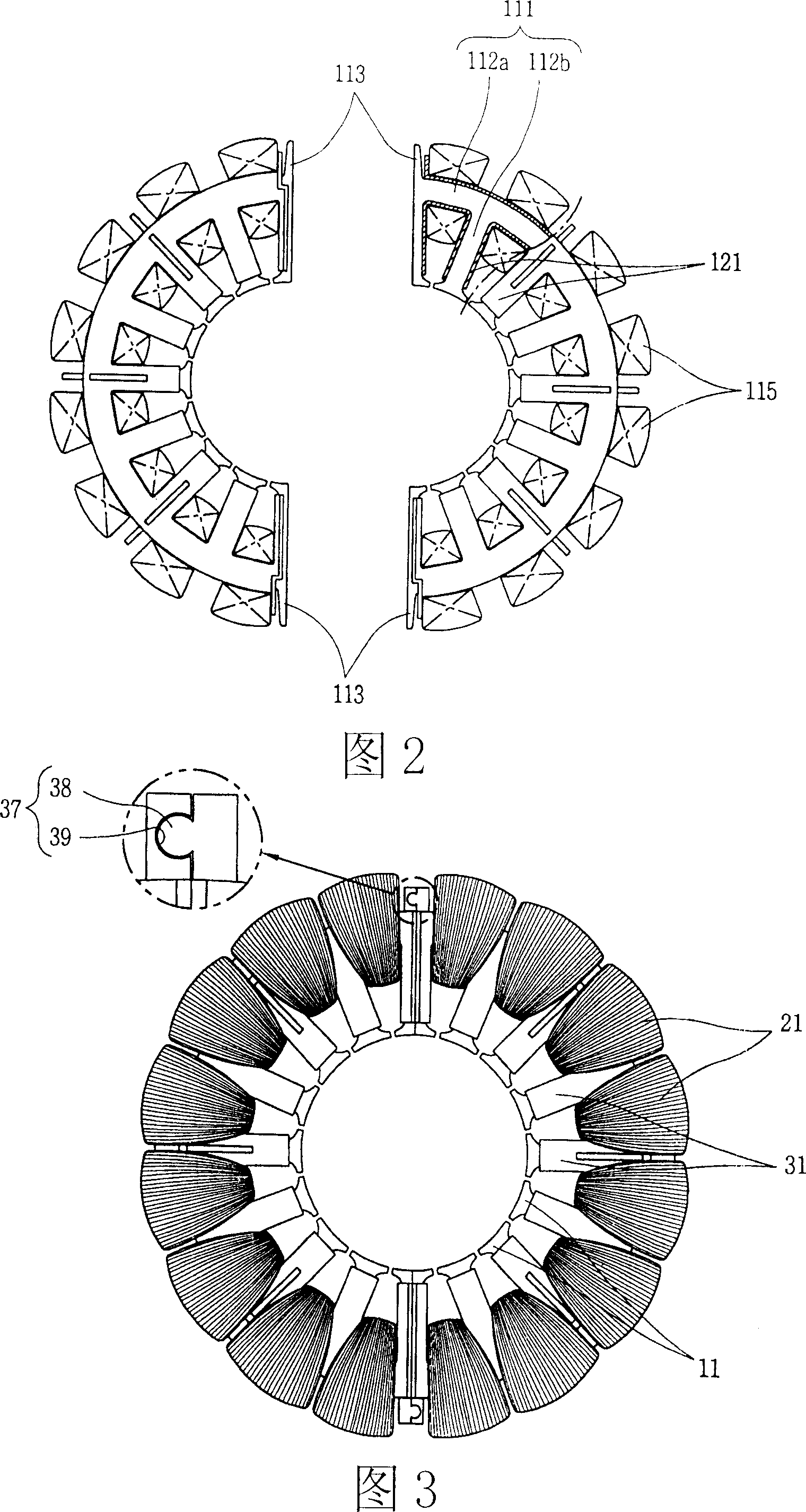

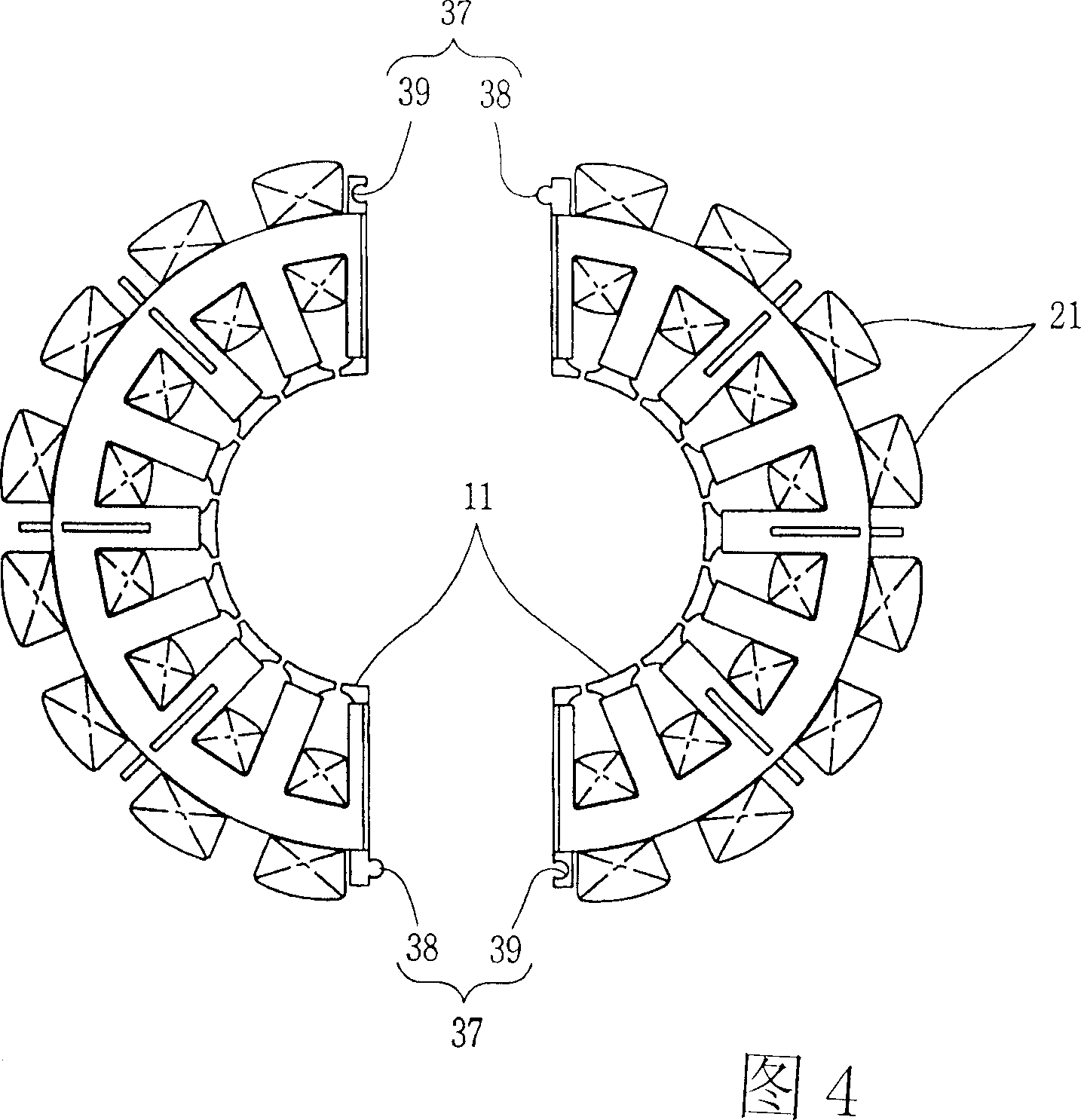

[0027] As shown in Figures 3 to 7, the stator of the ring motor in the present invention includes the following parts: an arc-shaped yoke portion 12a is provided, and protrudes toward the above-mentioned yoke portion 12a along the radial direction, and a predetermined distance along the peripheral direction to form a plurality of tooth portions 12b of slots 12c therebetween, and a plurality of split stator cores 11 combined with each other in order to form a ring shape; on the periphery of the above-mentioned yoke portion 12a The wound stator coil 21; a plurality of insulating members 31 that accommodate the yoke portion 12a and the tooth portion 12b inside and insulate the yoke portion 12a, the tooth portion 12b and the stator coil 21 from each other; One of the adjacent insulating members 31 is protrudingly provided with a coupling protrusion 38 toward the other, and the other of the mutually adjacent insulating members 31 is provided with a protrusion receiving portion 39 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com