High rate electrolyte for lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of electrolyte, can solve the problems of low power, low conductivity, and low contribution of lithium-ion conductivity in lithium-ion batteries, and achieve the goal of improving rate discharge characteristics and increasing dissociation degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

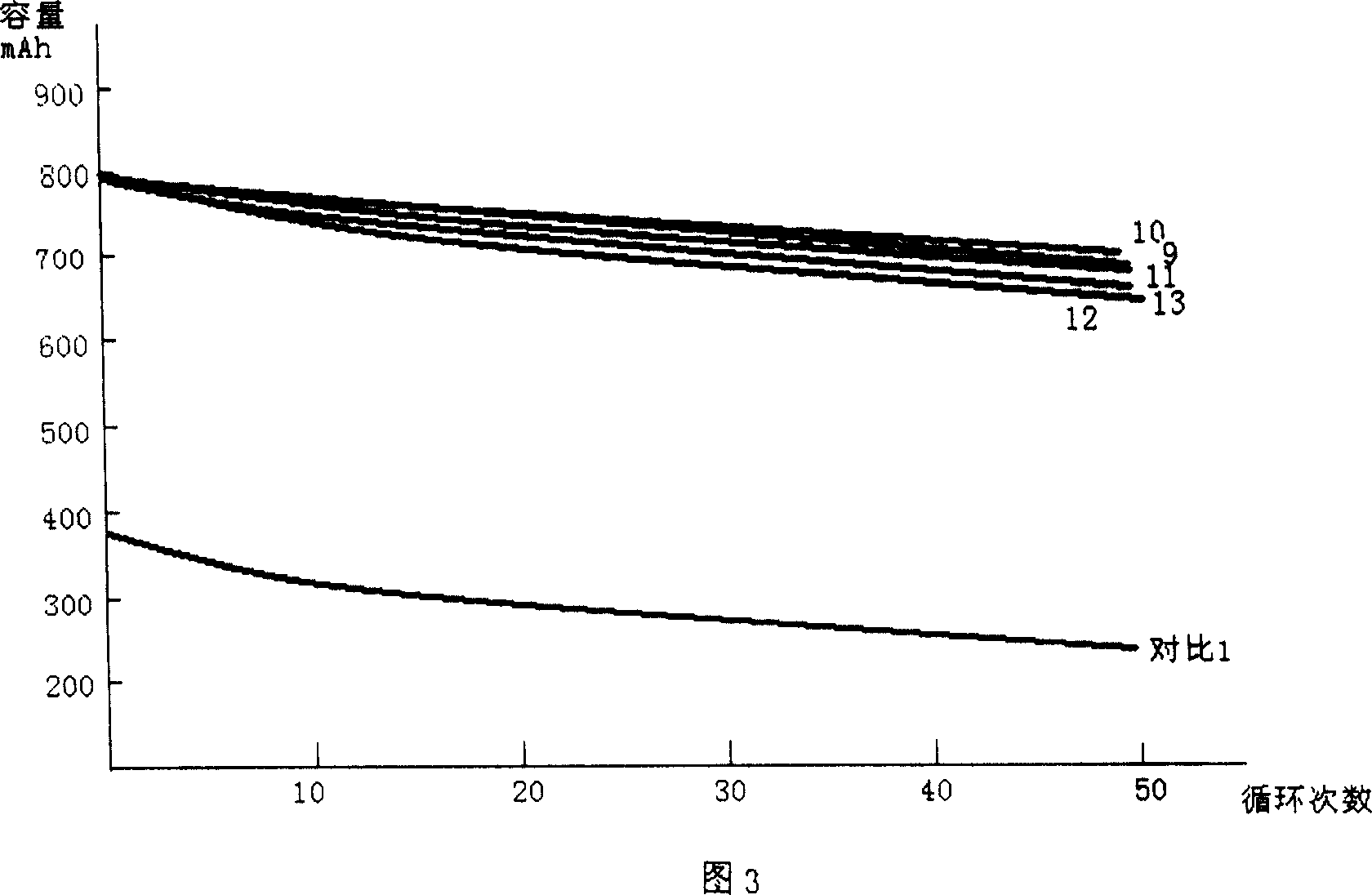

[0022] In the environment of normal temperature and pressure, moisture content 1ppm, and an inert gas environment, a solvent with a purity of more than 99.95%, 22.6% ethylene carbonate, 5.7% propylene carbonate, 39.3% dimethyl carbonate, and 16.6% ethyl methyl carbonate were mixed. Uniformly, dissolve 13.3% lithium salt LiPF in this mixed solvent 6 , add in three times on average, the time interval between each addition is 1.5-2.0 hours, shake well after adding, and finally add 1.5% functional additive vinylene carbonate and 1.0% acetamide.

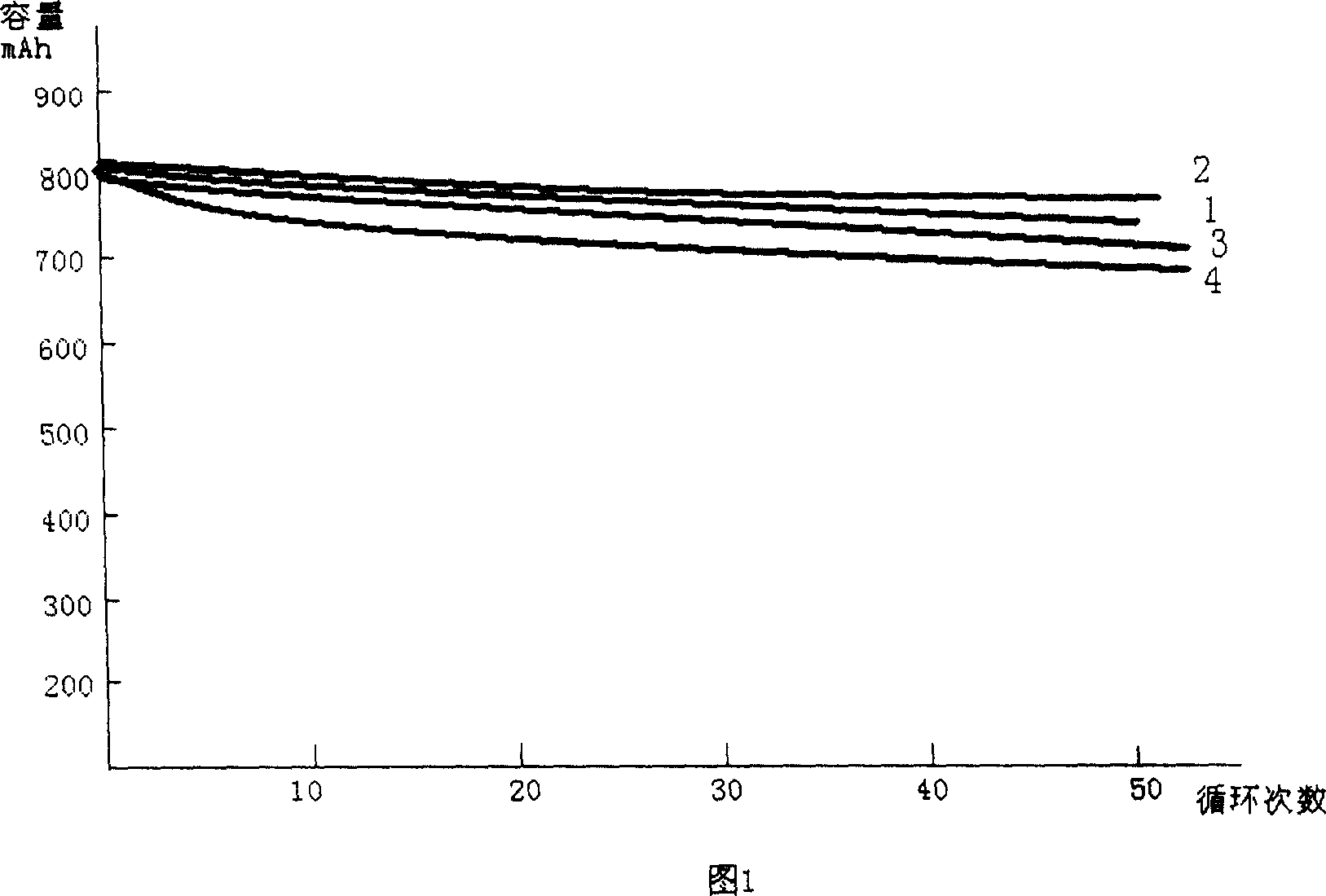

[0023] The electrolyte is filled into the battery for discharge characteristic detection, and the battery used is:

[0024] Positive electrode: active material LiCoO 2 The content of carbon black is 94%, carbon black is 3.0%, binder PVDF is 3.0%, and aluminum foil is the current collector. The width of the pole piece is 5.0cm, and the thickness is 147μm.

[0025] Negative electrode: the content of active material MCMB is 90.0%, the con...

Embodiment 2

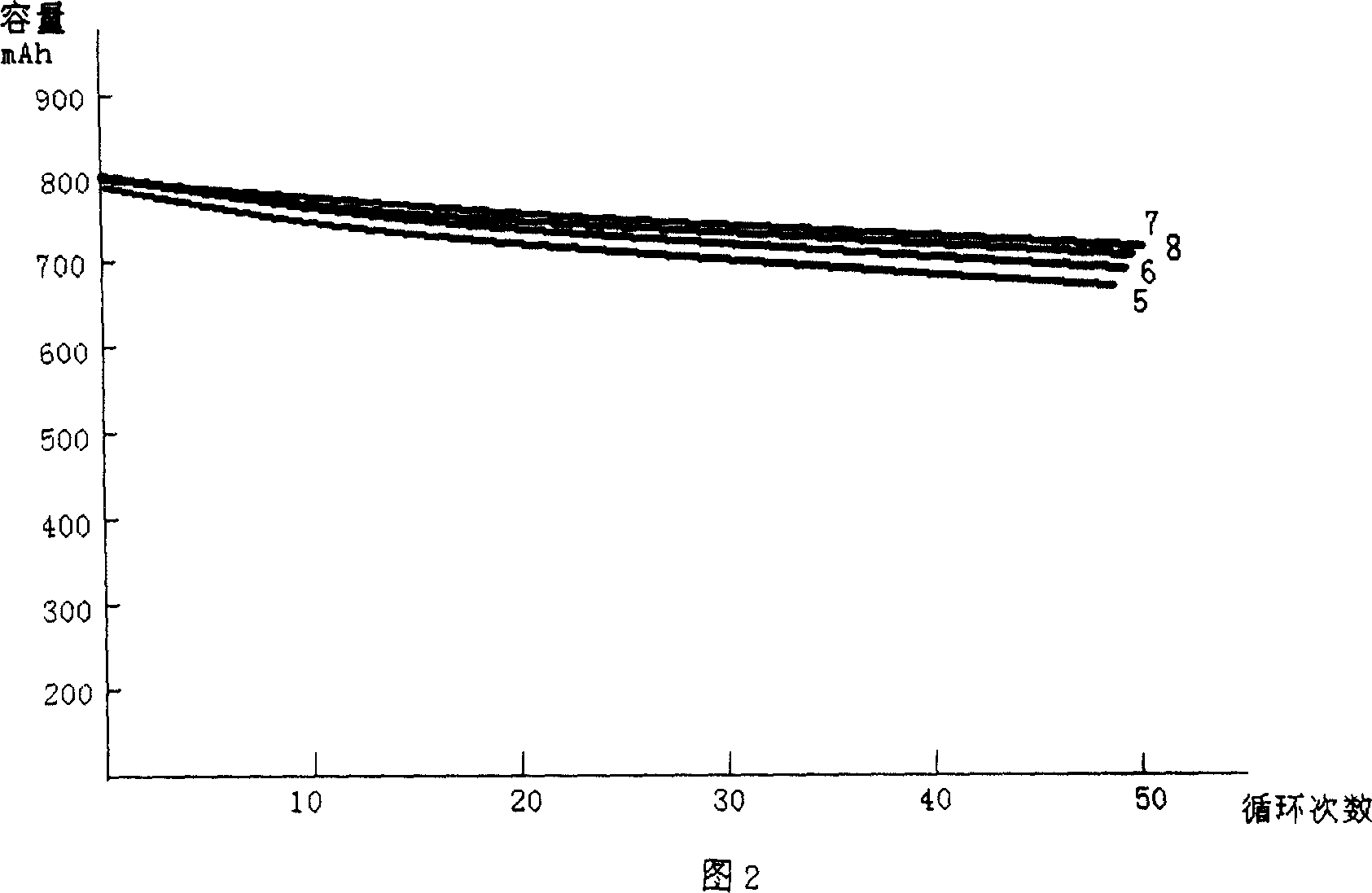

[0039] With embodiment 1, just lithium salt LiPF 6 Change to LiAsF 6 , the functional additive acetamide was replaced by 12 crown ether 4 of crown ether, and the obtained electrolyte was tested for moisture, pH, and conductivity.

Embodiment 3

[0041] With embodiment 1, just lithium salt LiPF 6 Replaced with 10.0% LiAsF 6 and 3.3% LiBOB, the functional additive vinylene carbonate was replaced by carbon dioxide, and the functional additive acetamide was replaced by liquid ammonia, and the obtained electrolyte was tested for moisture, pH and conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com